Non-broadening low-temperature-toughness ship plate marine steel and manufacturing method thereof

A low-temperature toughness and broadening technology, applied in temperature control and other directions, can solve problems such as limited production of steel plates, pauses in the rolling process, and restrictions on the length of steel billets, so as to ensure the performance of steel plates, refine the original grains, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation of the present invention will be further described below in conjunction with the examples, and the present invention is not limited to the scope of the examples.

[0047] A low-temperature ductile marine steel without broadening, the mass fraction of its chemical composition is: C 0.15-0.18%, Si 0.10-0.30%, Mn 1.15-1.45%, P≤0.015%, S≤0.005%, Als 0.008-0.020%, Nb 0.008-0.025%, Ti 0.008-0.014%, Ceq≤0.43%. The rest is Fe and unavoidable impurities.

[0048] The thickness range of the marine engineering steel plate of the ship plate is 4-50mm. Transverse yield strength is 380-420MPa, longitudinal yield strength is 375-415MPa, transverse tensile strength is 515-555MPa, longitudinal tensile strength is 510-550MPa, transverse impact energy at -60°C is 180-250J, longitudinal impact energy at -60°C is 210-270J, The performance ratio of horizontal and vertical steel plates is 0.93 to 1.02.

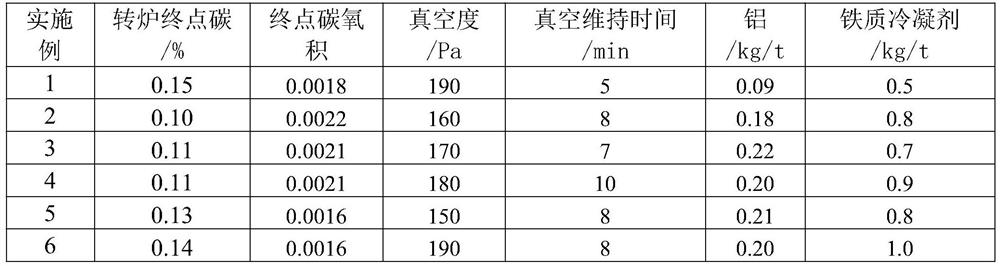

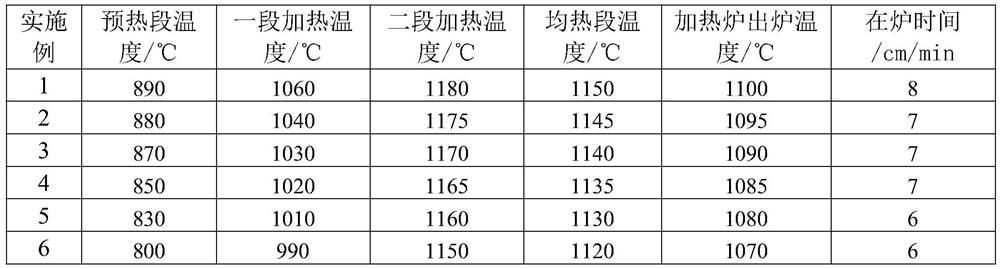

[0049] A method for manufacturing low-temperature ductile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com