Ice plug jacket device for inspection and maintenance of metal face seal joints

A technology for sealing joints and metal surfaces, which is applied to workpiece clamping devices, manufacturing tools, etc., and can solve problems such as remote monitoring and rapid thawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

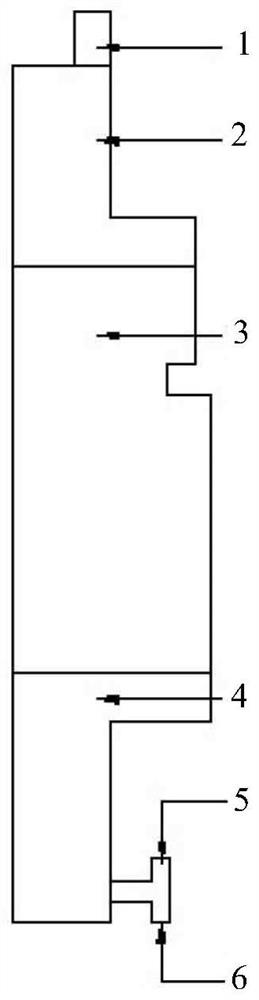

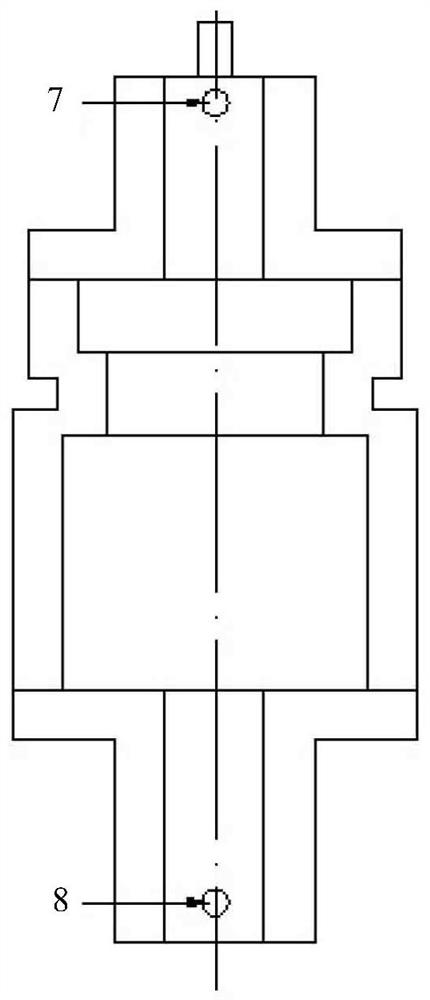

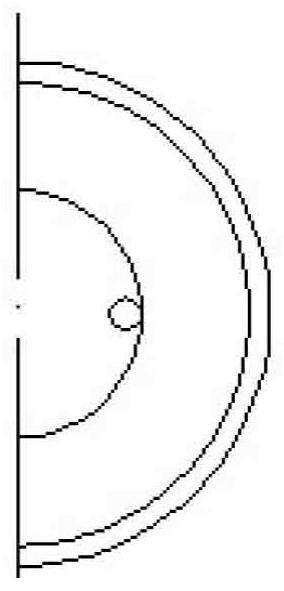

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] The commonly used methods of ice plug technology are liquid nitrogen method, dry ice method and electric refrigeration method. The medium temperature of the ice plug system made by the liquid nitrogen method is lower than 50°C, and the medium temperature of the ice plug system made by the dry ice method and the electric refrigeration method is lower than 30°C. During the ice plug production process, the unilateral pressure method, hydrophobic method, ultrasonic detection method, frost observation method, and pipe wall temperature measurement method are commonly used to detect whether the ice plug is successfully made. In the combined electrolytic catalytic exchange system, the medium pipeline and equipment are connected through VCR joints, and the maximum temperature in the pipeline is lower than 50°C. The main device for making ice plugs by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com