Diaphragm vacuum pump

A vacuum pump and diaphragm technology, applied in the direction of pump, pump control, pump components, etc., can solve the problems of diaphragm vacuum pump diaphragm aging and damage, shortening of diaphragm vacuum pump life, liquid or water vapor entering, etc., to improve condensation effect and improve service life. , the effect of increasing the duration of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

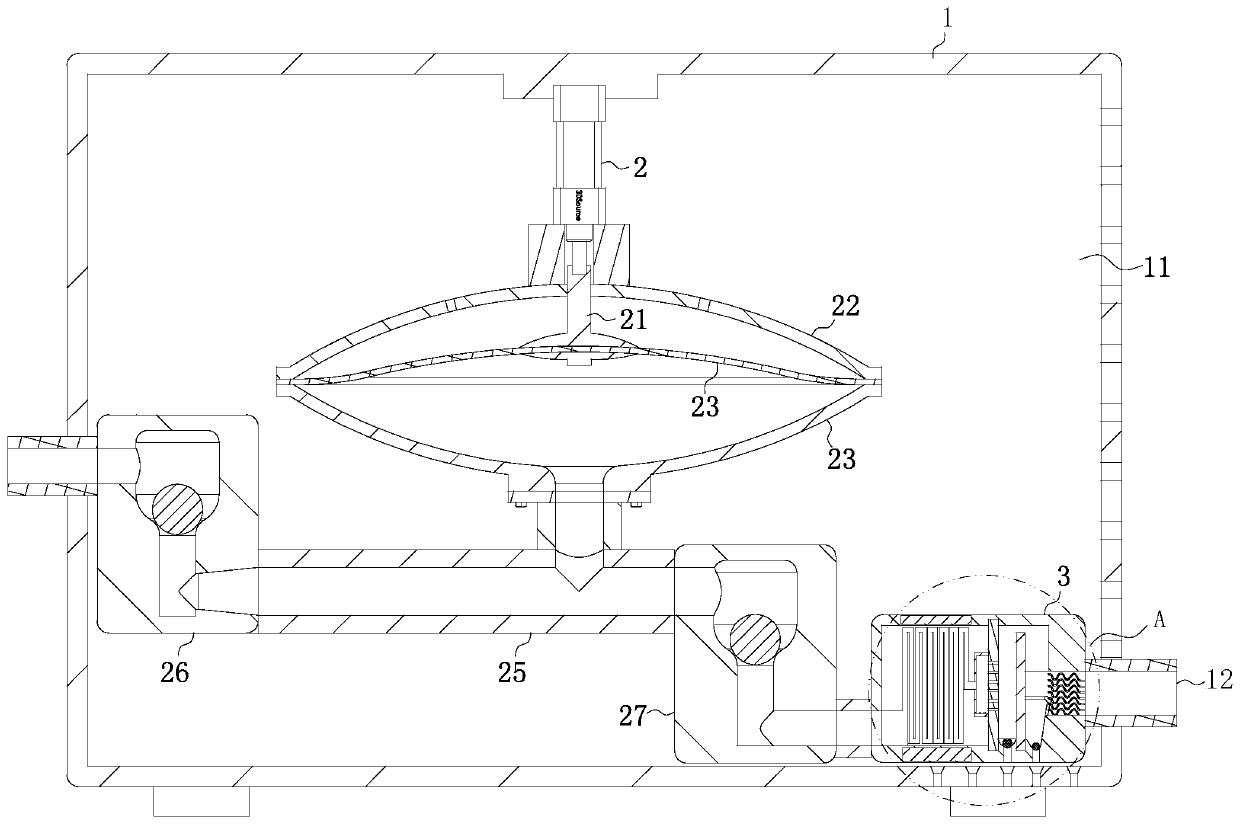

[0024] As an embodiment of the present invention, the left side of the orifice plate 31 is fixedly connected with an air-container cover 37 at the position of the air guide hole 32; two electrical connectors 38 are fixedly connected with the lower surface inside the air-container cover 37; There is a gap space between the two electrical connectors 38; during operation, when a large amount of liquid enters the diaphragm vacuum pump uncontrollably, the liquid will pass through the air guide hole 32 on the first orifice plate 31 and enter the air containment cover 37 and then further introduced into the interior of the vacuum pump next door, so in order to prevent the liquid from being further introduced through the container cover, by setting two electrical connectors 38 at the bottom of the container cover, if there is liquid flowing in, the two electrical connectors 38 will be caused by liquid When it is turned on, the electrical signal that is turned on will make the diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com