Auxiliary self-locking protection mechanism used for electric steam boiler

A technology of steam boiler and self-locking protection, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve problems such as paralysis, damage, and dry burning of heating pipes, and achieve sensitive induction, prevention of dry burning, and protection. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

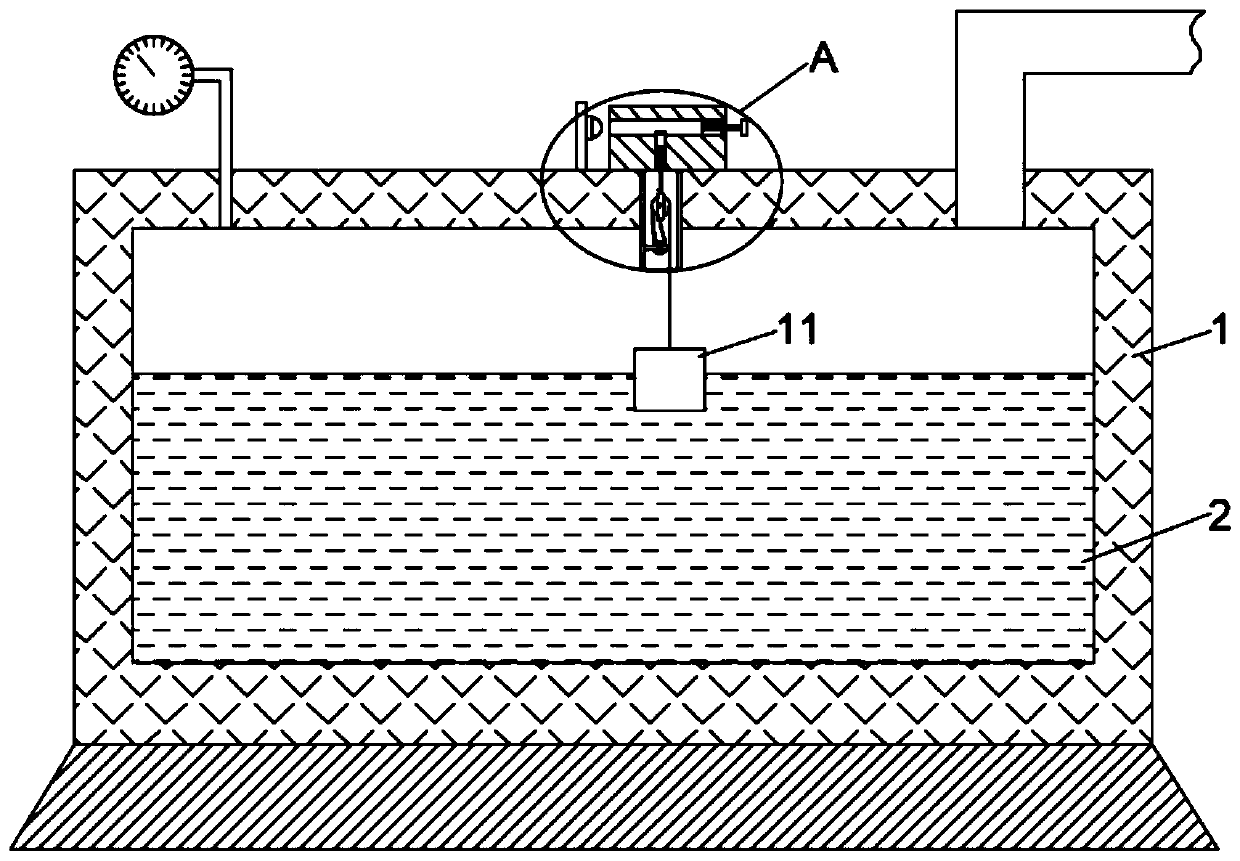

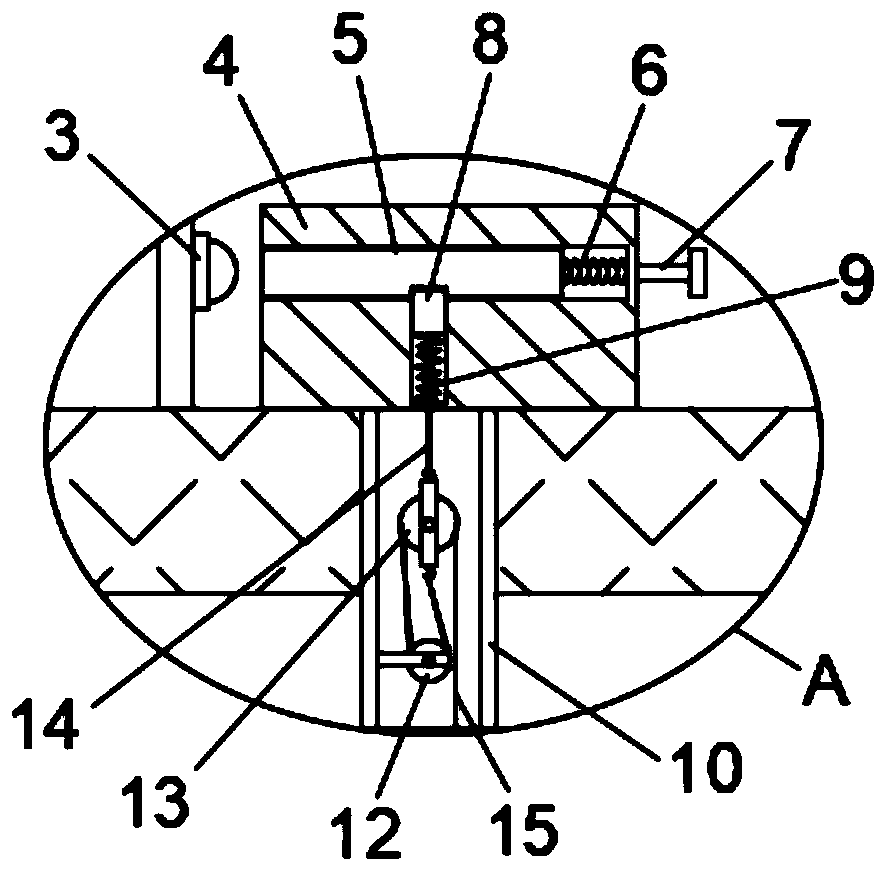

[0015] refer to Figure 1-2 , an auxiliary self-locking protection mechanism for an electric steam boiler, including a boiler body 1 and a furnace cylinder 2, a power-off self-locking switch 3 is installed on the upper end of the boiler body 1, and a fixed connection is made on the boiler body 1 located on one side of the power-off self-locking switch 3 The fixed seat 4, the side of the fixed seat 4 close to the power-off self-locking switch 3 is provided with a chute, the inside of the chute slides horizontally with a trigger block 5, and the end of the trigger block 5 away from the power-off self-locking switch 3 is fixedly connected with the inner wall of the chute The first spring 6, the end of the trigger block 5 away from the power failure self-locking switch 3 is also fixedly connected with a cross bar 7, and the first spring 6 is sleeved on the outside of the cross bar 7;

[0016] The other end of the cross bar 7 runs through the fixing seat 4, and a groove is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com