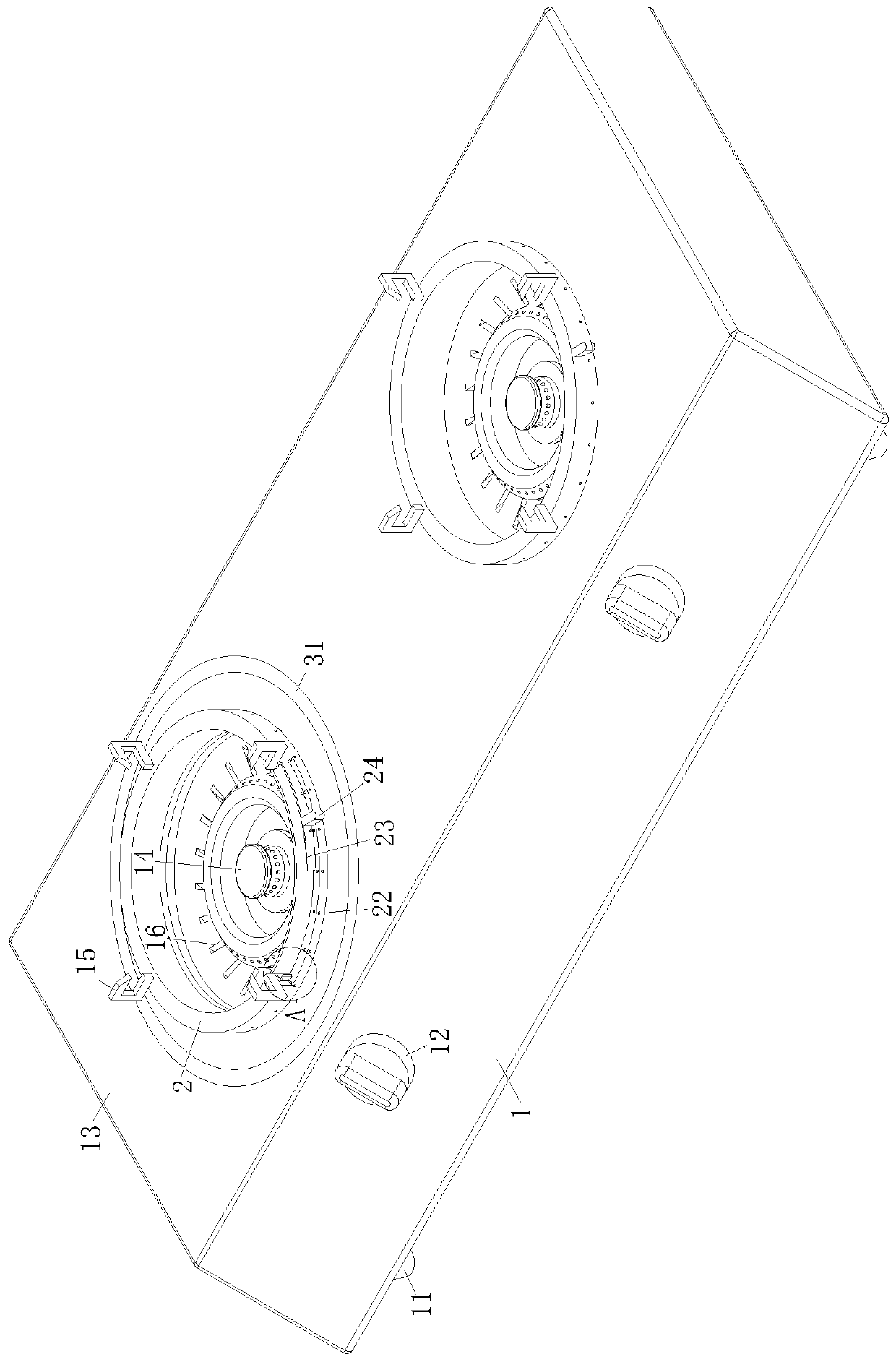

Gas stove

A gas stove and stove body technology, applied in the field of gas stoves, can solve the problems of inconvenient operation, hidden dangers, scalds, etc., and achieve the effects of increasing the safety of use and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

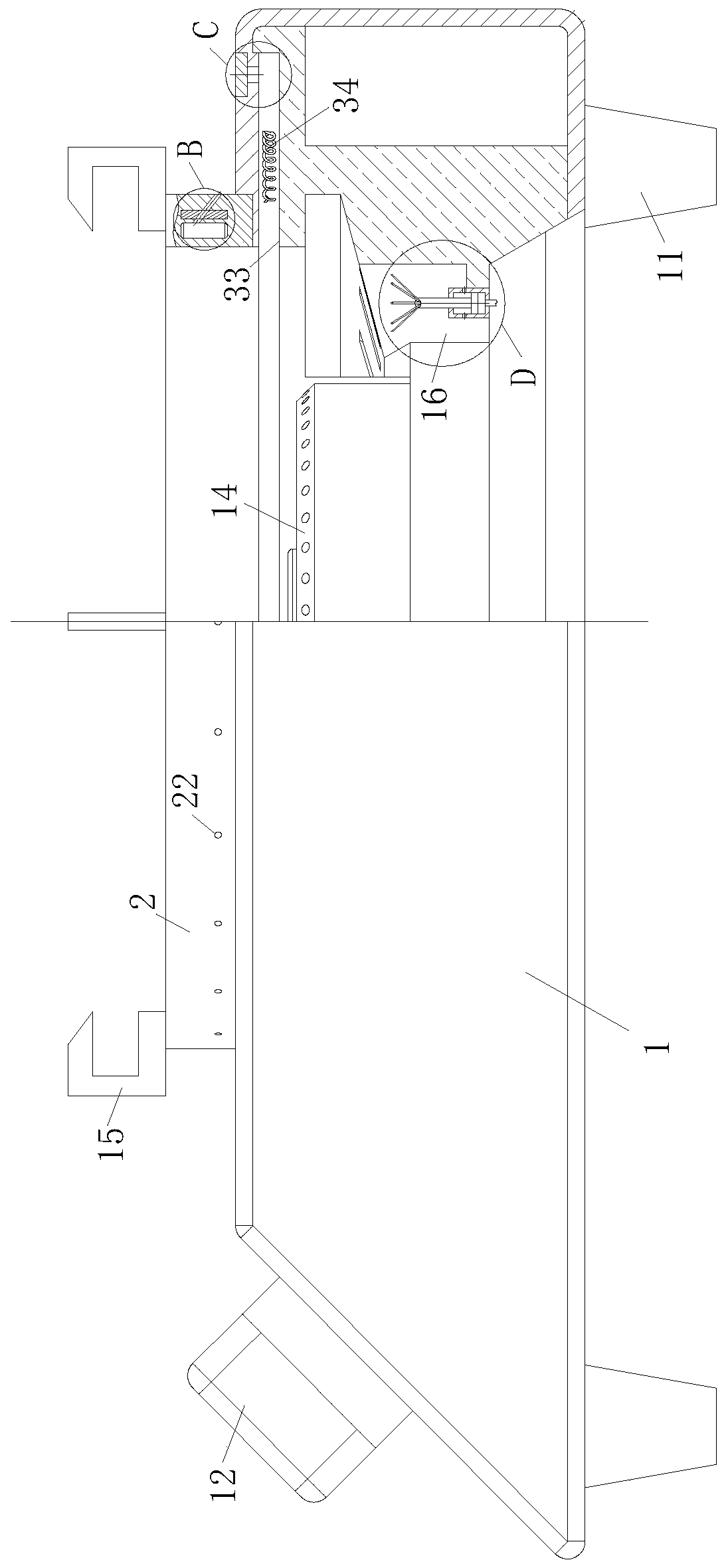

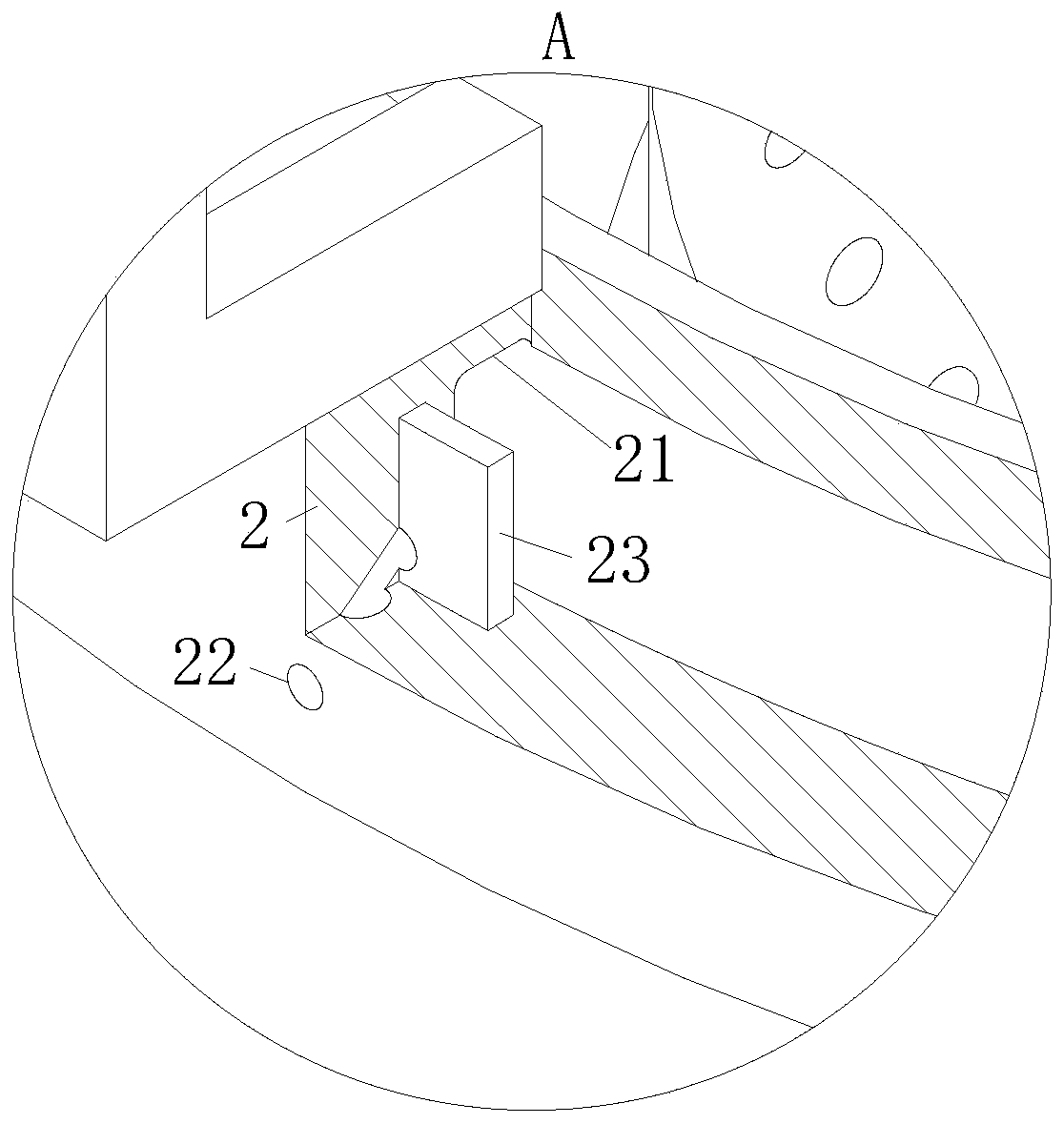

[0025] As an embodiment of the present invention, a group of spray holes 22 communicating with the water chamber 21 is evenly distributed on the circumference of the boss 2, and the side of the spray hole 22 axis close to the water chamber 21 is inclined upward; the outside of the water chamber 21 A snap ring 23 is slidably connected to the boss 2, and a driving rod 24 is fixedly connected to the snap ring 23, and the driving rod 24 extends outside the boss 2; the snap ring 23 is provided with a through hole 25 corresponding to the nozzle hole 22. Rotate the snap ring 23 by the driving lever 24, so that the steam in the water chamber 21 is sprayed to the top plate 13, which is convenient for cleaning the greasy dirt on the top plate 13; If there is a lot of oil, turn the lever 24 at this time, so that the through hole 25 on the snap ring 23 is aligned with the nozzle hole 22 after the snap ring 23 slides, and then the water vapor in the water chamber 21 is ejected from the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com