Forging resistance furnace production optimization method based on SPEA2 algorithm

An optimization method and resistance furnace technology, applied in constraint-based CAD, design optimization/simulation, calculation, etc., can solve problems such as poor capacity and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

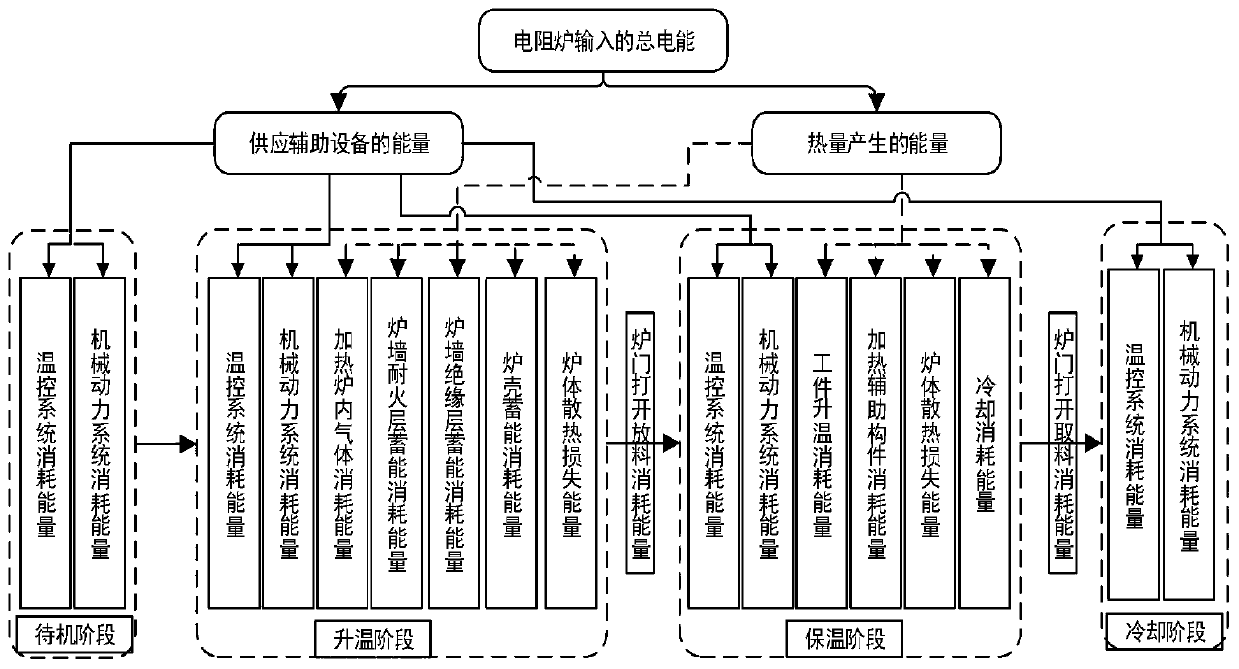

[0120] This application adopts a resistance furnace production optimization method based on the SPEA2 algorithm to solve the technical problems of the lowest forging total energy consumption, the shortest forging heating time, and the smallest difference in furnace charging capacity (that is, the highest effective utilization rate of the resistance furnace) in the resistance furnace production process. .

[0121] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings of the specification and specific case implementations.

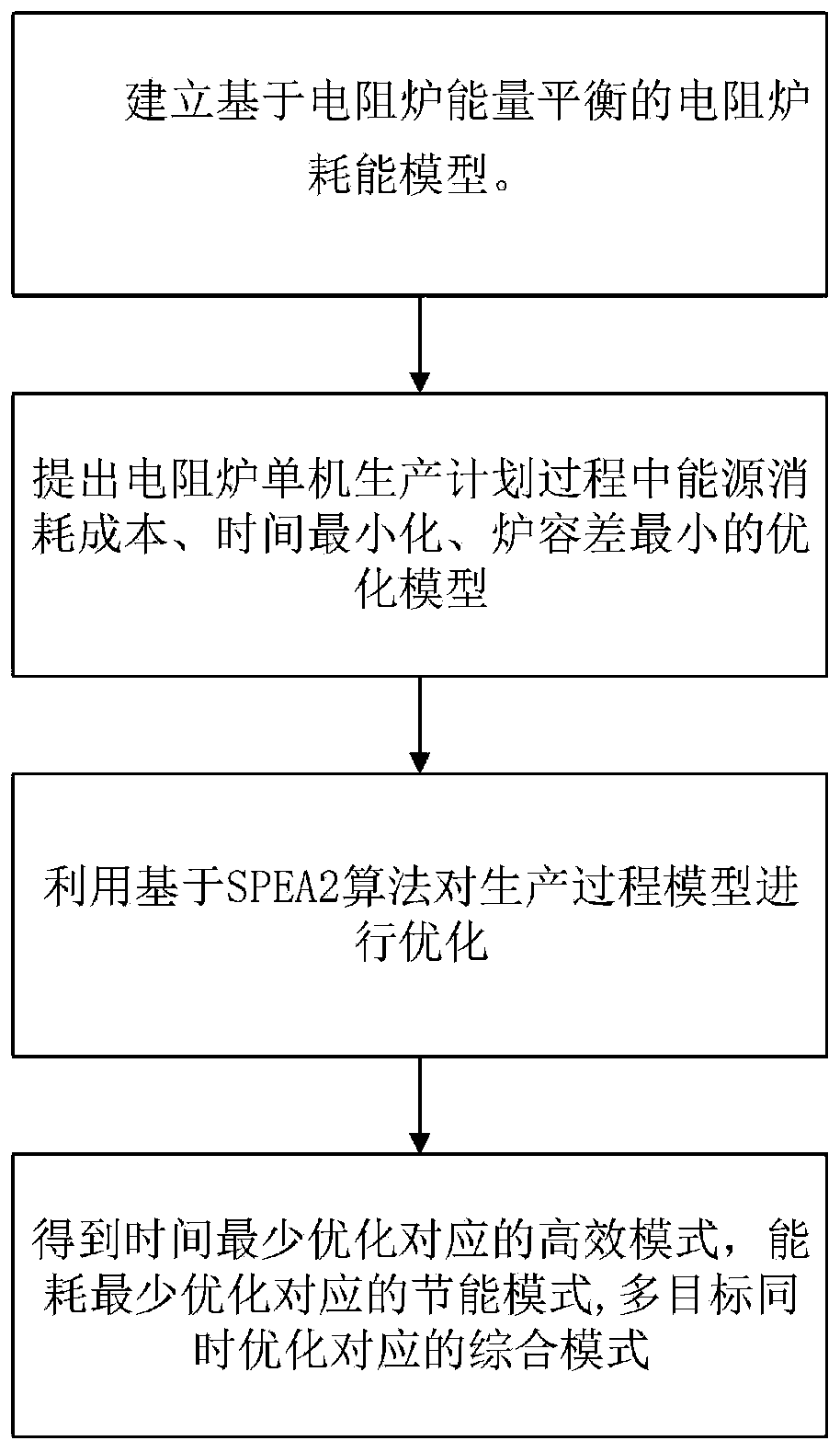

[0122] A resistance furnace production optimization method based on the SPEA2 algorithm, the specific steps are as follows figure 1 shown.

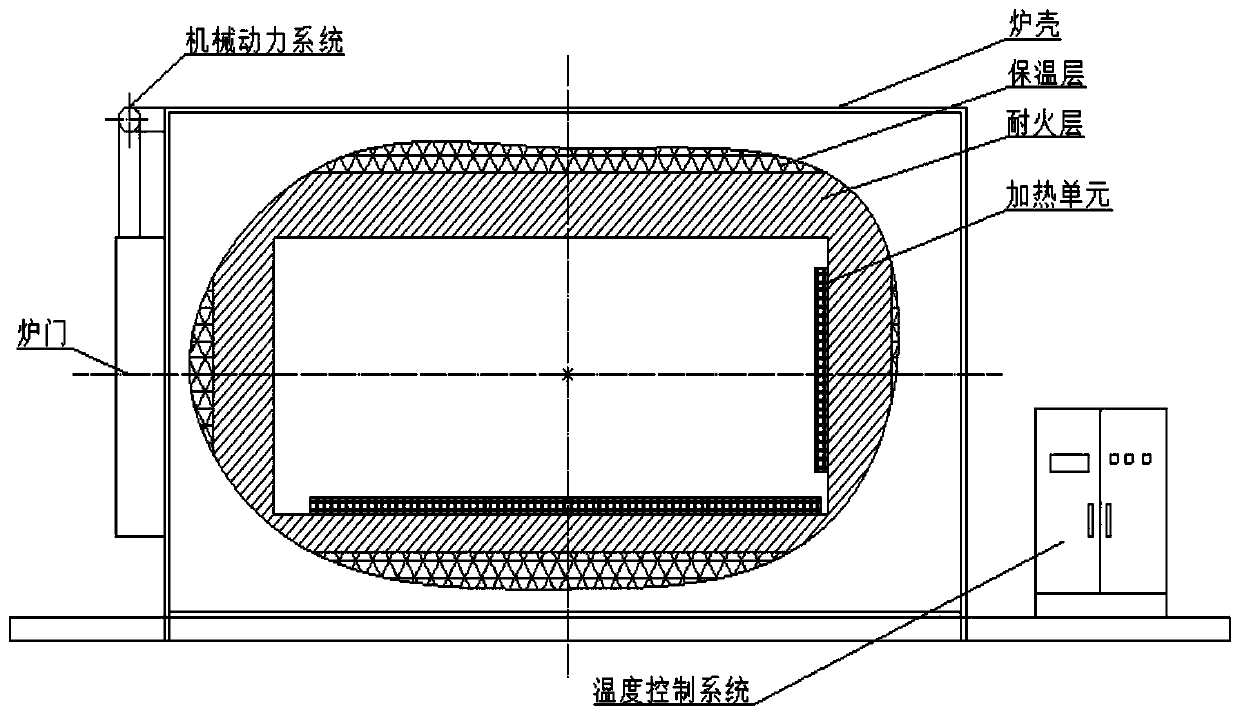

[0123] Take the RJX-75-9 medium temperature resistance furnace as an example ( figure 2 ), the implementation steps of the present invention are as follows:

[0124] Step 1 analyzes ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap