Continuous casting vibrating support roller with built-in eccentric rotating mechanism

A technology of eccentric rotation and support roller, applied in the field of metal solidification and continuous casting, can solve the problem of no equipment structure plan, and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

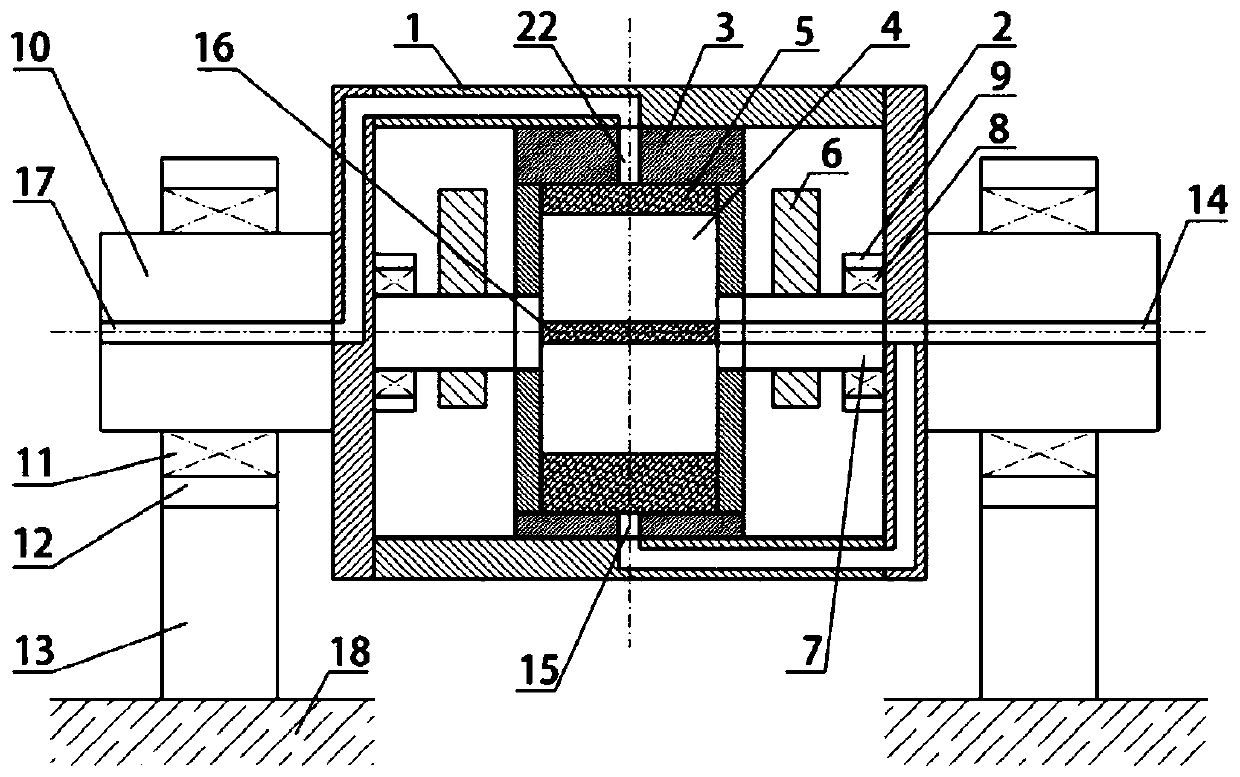

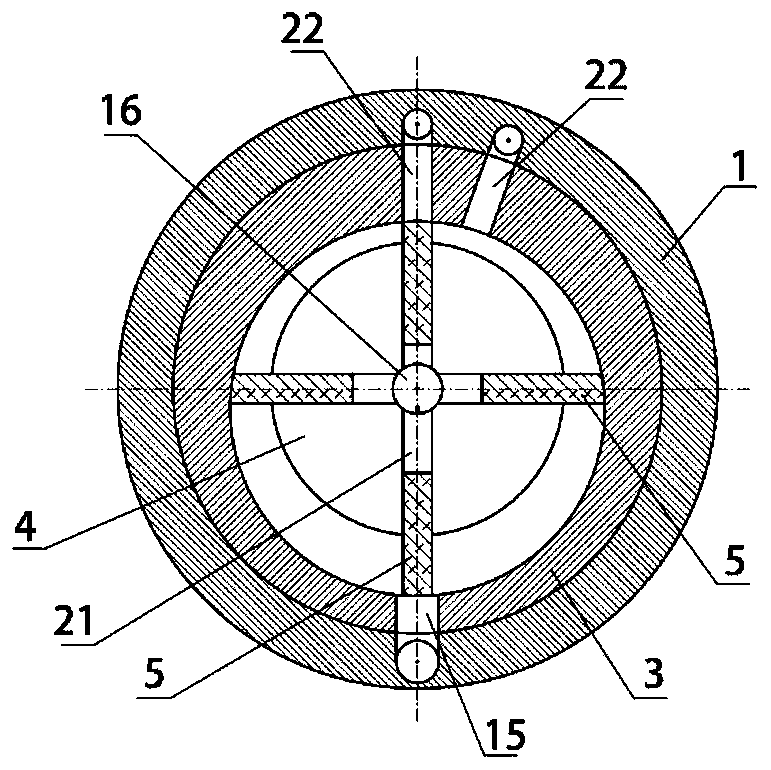

[0067] Example 1 - Continuous casting vibrating support roll with built-in eccentric rotation device (single rotor)

[0068] see figure 1 , it mainly includes: vibration support roller body 1, end covers 2 on both sides, rotor shell 3, rotor 4, movable blade 5, eccentric block 6, rotor rotating shaft 7, rotor rotating shaft bearing 8, rotor rotating shaft bearing Seat 9, rotating shaft 10, bearing 11, bearing seat 12, elastic support seat 13, air intake channel 14 (including: radial air intake hole 15, central air intake groove 16), air outlet channel 17, base stand 18 and so on. During use, the vibrating support roll body 1 is in contact with the casting strand 19 and rotates with the movement of the casting strand.

[0069] Structurally, the vibrating support roller body 1 is mechanically connected to the end covers 2 on both sides (such as bolts, pins, etc.) to facilitate disassembly and maintenance. The end cover 2 can be connected with the rotor rotating shaft bearin...

Embodiment 2

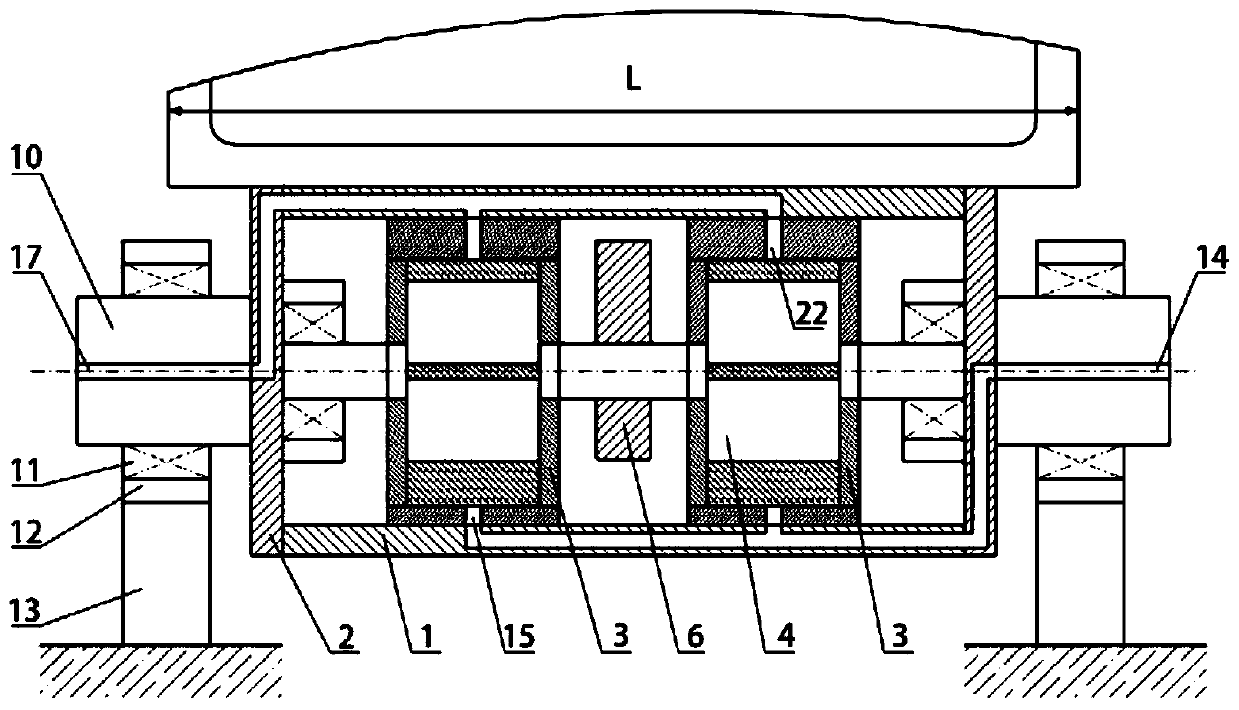

[0075] Example 2 - Vibrating support rolls for continuous casting (multiple rotors) with built-in eccentric rotation

[0076] In the present invention, there may be multiple rotor housings 3, rotors 4, etc., to drive an eccentric block 6 to rotate, see figure 2 .

Embodiment 3

[0077] Example 3 - The rotor is a fixed blade

[0078] The present invention can also be a fixed blade, that is, the axial flow blade 20, and the axial flow is on the rotor 4. At this time, the rotor housing 3 may not be needed; the compressed air flows in from one side and flows out from the other side to pass through the axial flow blade 20 promote the eccentric block 6 to rotate, see Figure 4 .

[0079] In use, at the same cross-sectional position of the slab, the vibrating support roller can be placed on one side of the slab, or can be placed on symmetrical two or more sides of the sub-slab, as shown in Fig. 6 .

[0080] The shape of vibrating support roll roll body 1 section can be rectangular, see figure 1 , can also be trapezoidal, stepped, circular, convex arc, concave arc or not limited to the above-mentioned shapes, see FIG. 7 .

[0081] When in use, the vibrating support roll can be placed at the lower end of the mold outlet of the continuous casting machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com