3D printer for mechanical product forming proofing

A technology for 3D printers and mechanical products, applied in the field of 3D printers for molding and proofing of mechanical products, it can solve the problems that are not mentioned, the printed products do not meet the production requirements, and the manual cleaning is not comprehensive, so as to ensure the accuracy of the position and the guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

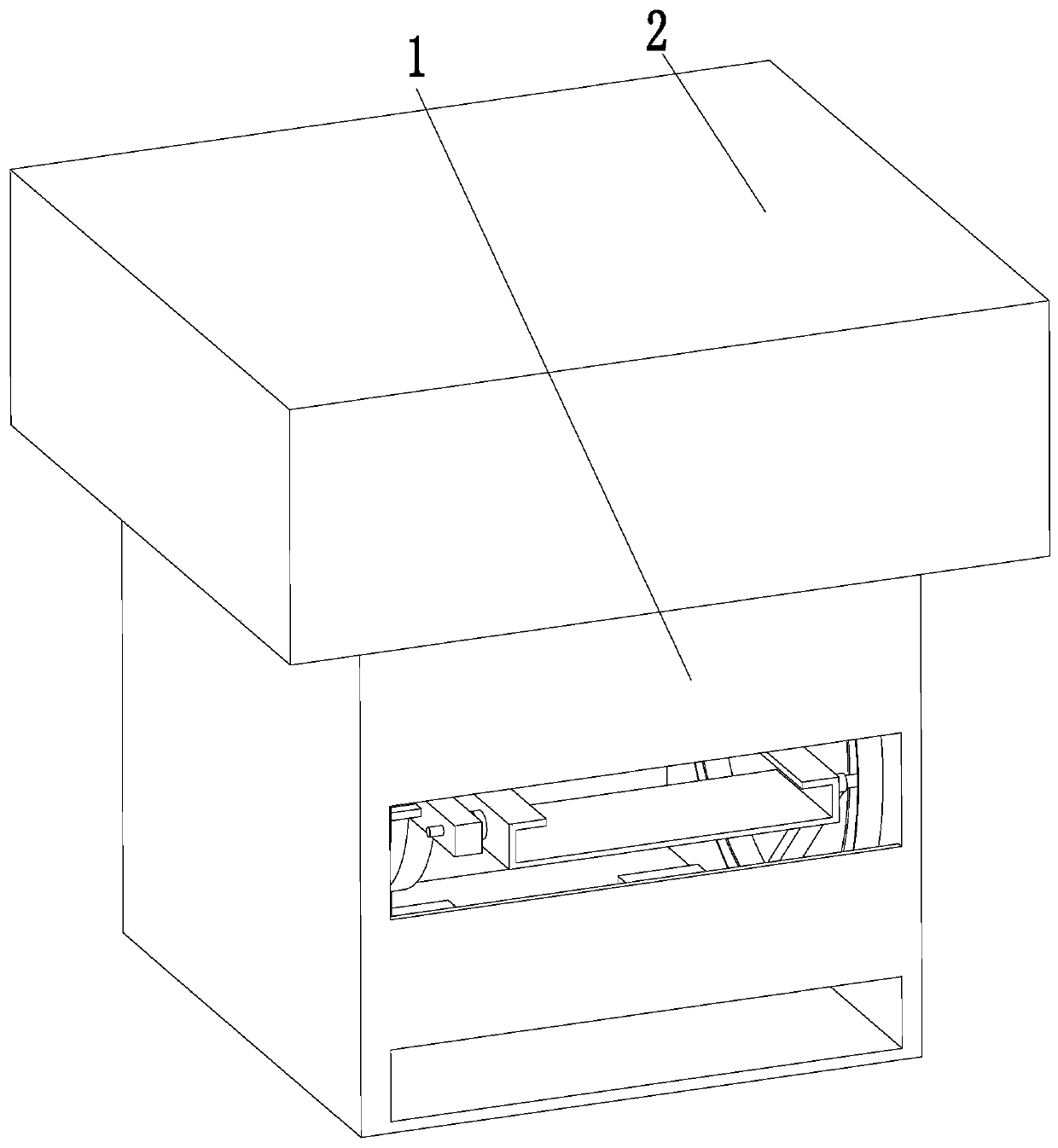

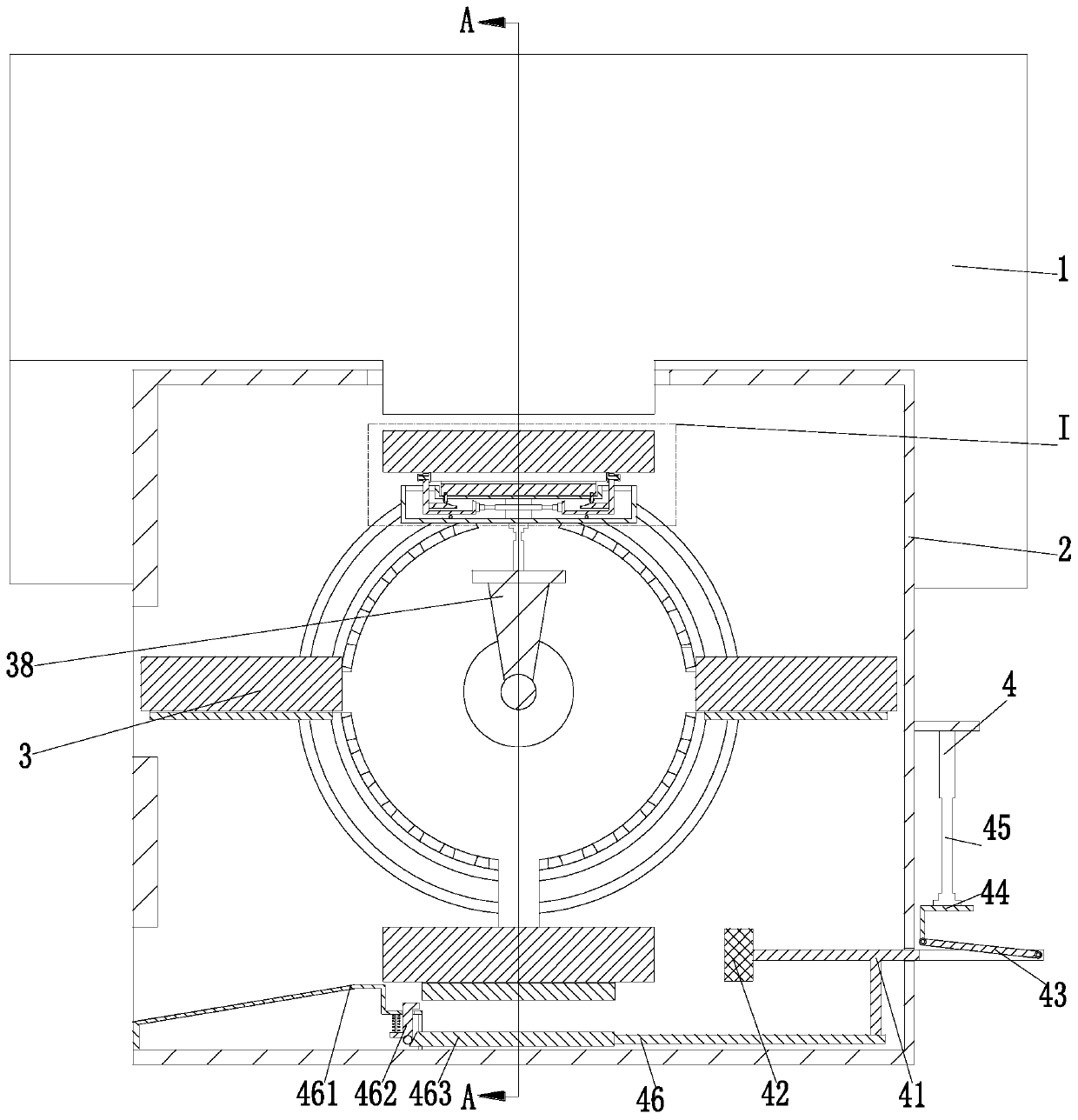

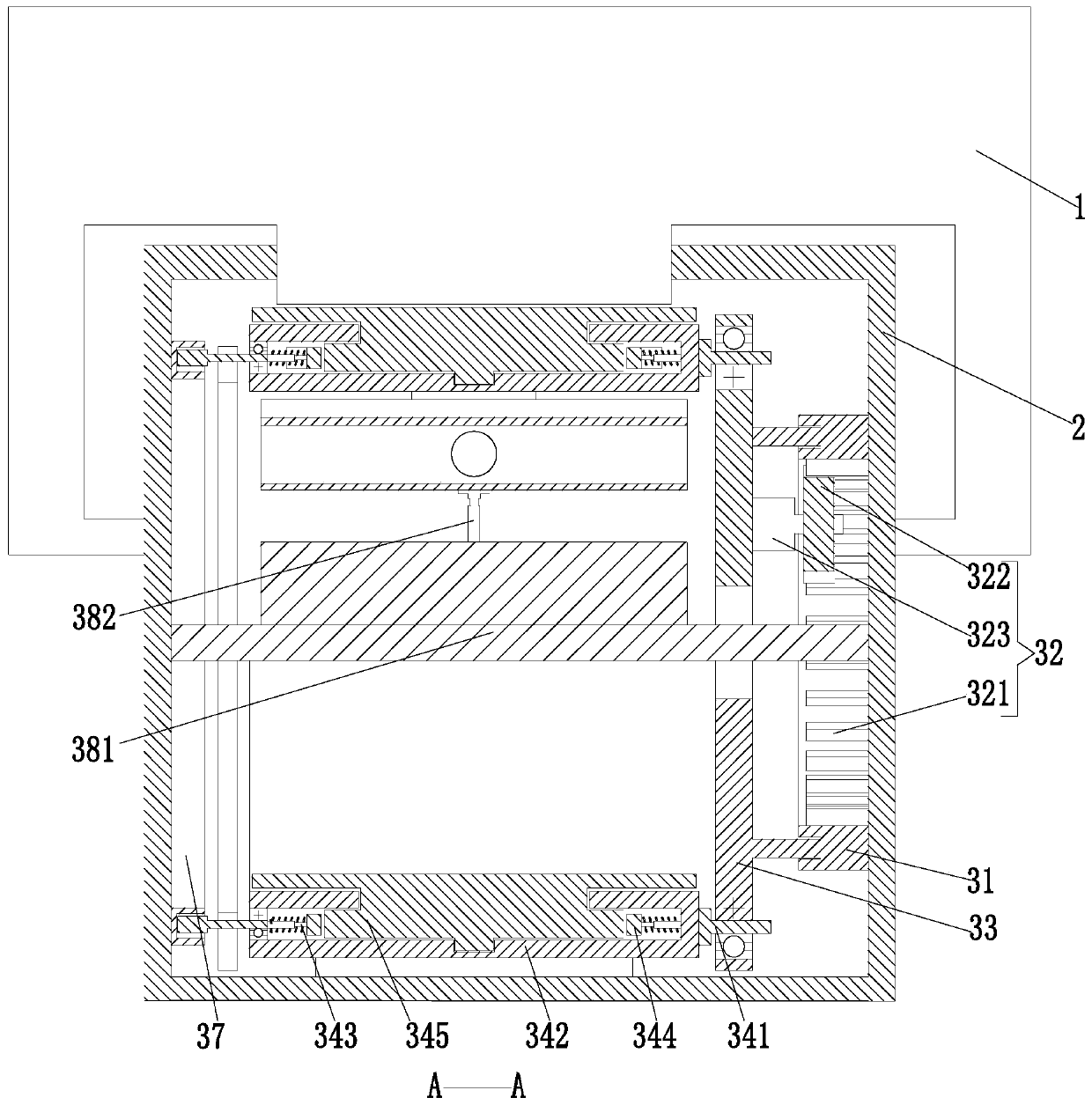

[0026] Such as Figure 1 to Figure 5 As shown, a 3D printer for molding and proofing mechanical products includes a printer body 1. A housing frame 2 is installed at the lower end of the printer body 1. A placement opening is opened on the upper side of the front end of the housing frame 2. An outlet is provided on the lower side of the front end of the housing frame 2. In the feed port, a rotating device 3 is provided between the inner walls of the housing frame 2, and a pushing device 4 is provided at the rear end of the housing frame 2;

[0027] The rotating device 3 includes an annular slideway 31 installed on the outer wall of the left end of the housing frame 2, the inner wall of the annular slideway 31 is provided with a driving mechanism 32,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com