High-temperature foam stabilizer and foaming liquid of giant surfactants, preparation method and application thereof

A surfactant and foaming liquid technology, applied in the field of high-temperature foam stabilizers, can solve the problem of decreased viscosity-increasing performance of surface-active hydrophilic polymers, oil reservoir damage, reduced foaming liquid foaming performance and foam stability Improve the expansion modulus, improve the oil recovery rate, and enhance the foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Another aspect of the present invention provides a kind of preparation method of described high-temperature foam stabilizer, wherein said method comprises the following steps:

[0058] (1) In the presence of an oxime connection reaction catalyst and a thiol-ene addition reaction photoinitiator, under ultraviolet light irradiation, the aldehyde group vinyl oligomeric silsesquike siloxane of formula (VII), formula (IV ) of aminooxypolystyrene and 2-mercaptoacetic acid react in a solvent;

[0059] (2) Cool the reaction solution in step (1) in cooling liquid until precipitation occurs.

[0060] In a preferred embodiment of the inventive method, the mass ratio of the aldehyde group vinyl oligomeric silsesquicage siloxane of formula (VII), the aminooxypolystyrene of formula (IV) and 2-mercaptoacetic acid is 2 -12:18-32:5-13, preferably 4-10:20-30:7-11, more preferably 5-8:23-28:7.5-10;

[0061] In a preferred embodiment of the method of the present invention, the catalyst f...

Embodiment 1

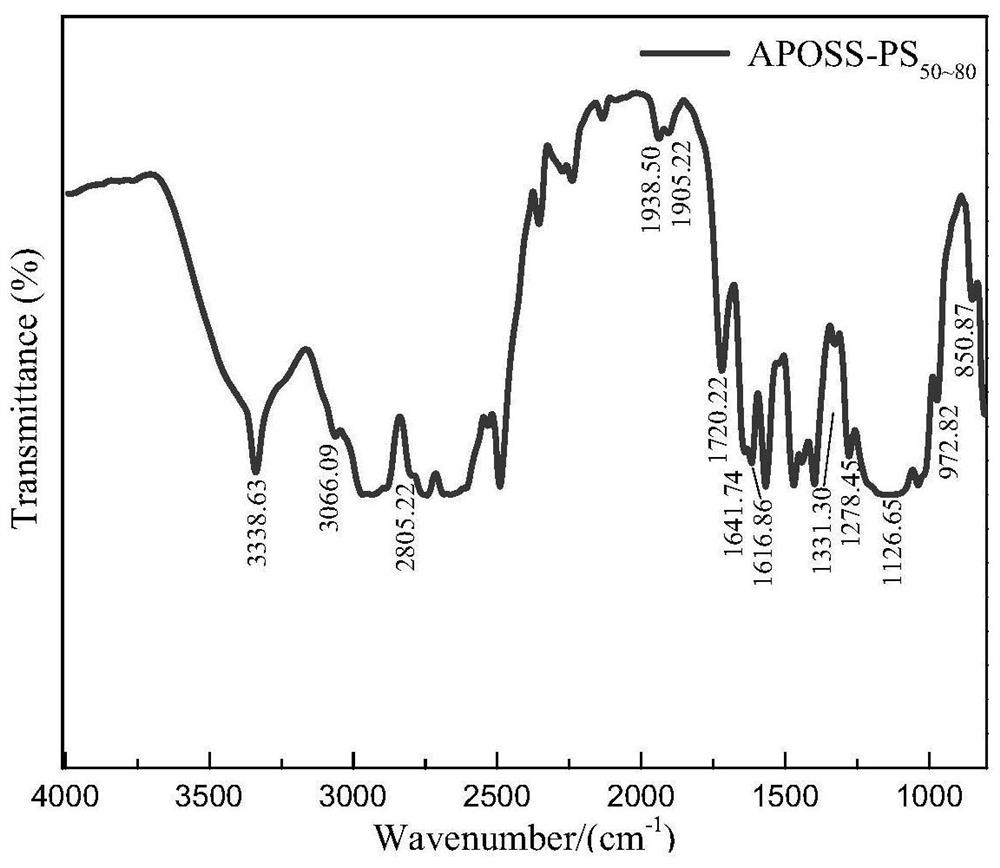

[0140] The high-temperature foam stabilizer (APOSS-PS of formula (I) of giant surfactant class of the present invention 50-80 , n is 50-80. ) for infrared spectroscopic analysis, see figure 1 .

[0141] The results of infrared spectroscopy were as figure 1 As shown, 3338.63cm -1 The place is the stretching vibration peak of hydroxyl O-H in the carboxyl group; 3066.09cm -1 It is the C-H stretching vibration peak of the aromatic ring; 2805.22cm -1 For the structural unit "-O-CH 2 "C-H stretching vibration peak; 1938.50cm -1 and 1905.22cm -1 It is the C-H out-of-plane bending vibration peak of aromatic compounds; 1720.22cm -1 The place is the C=O stretching vibration peak of the carbonyl group in the carboxyl group; 1641.74cm -1 and 1616.86cm -1 It is the C=C stretching vibration peak of the aromatic ring skeleton; 1331.30cm -1 and 1278.45cm -1 It is the carboxyl C-O stretching vibration peak; 1126.65cm -1 It is the Si-O-Si stretching vibration peak; 972.82cm-1 is th...

Embodiment 2

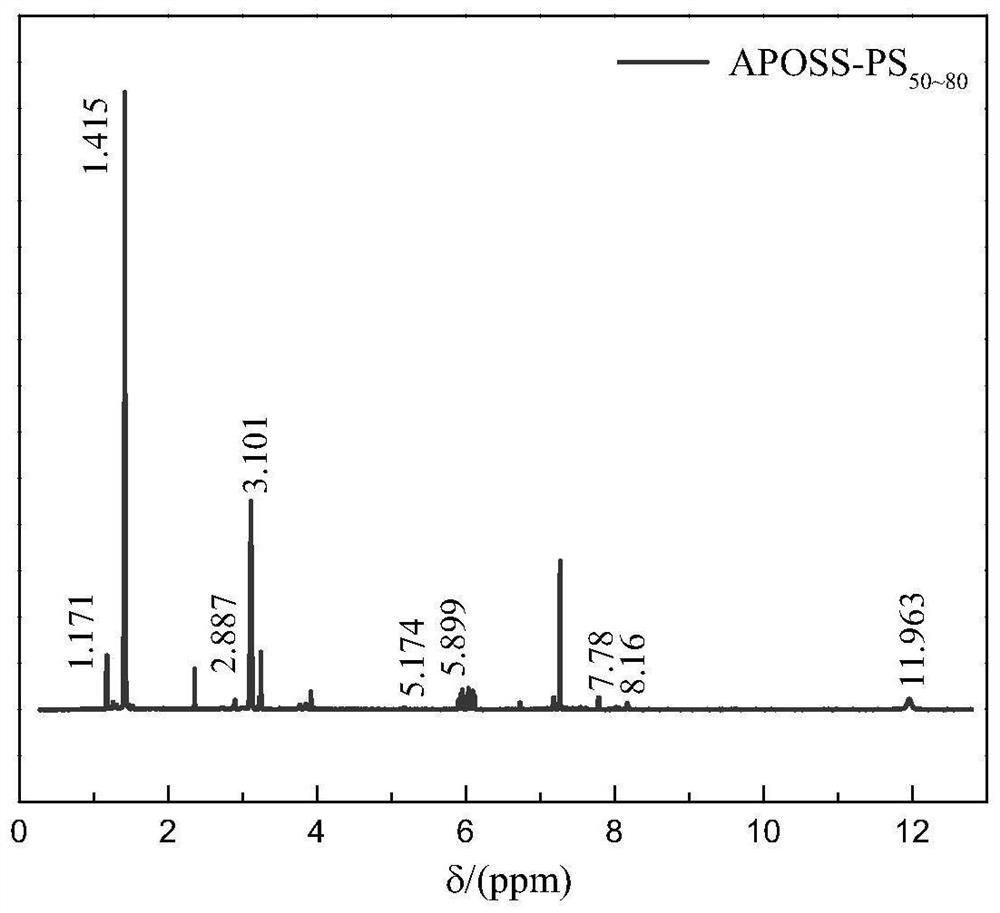

[0143] The nuclear magnetic resonance 1H-NMR analysis of high temperature foam stabilizer of the present invention, see figure 2 .

[0144] The results of H NMR spectroscopy were as follows: figure 2 Shown, δ=11.963ppm place is the proton signal in the carboxyl group, and the triplet peak that occurs at δ=8.16-8.18ppm place is the absorption peak of No. (1) proton in structural unit 1; Peak is the absorption peak of No. (2) proton in structural unit 1; The multiple peak that occurs at δ=5.899-6.124ppm place is the proton absorption peak of aromatic ring in polystyrene structural unit; δ=5.174ppm place is in structural unit 2 (3) the absorption peak of No. proton; The triplet peak that occurs at δ=3.101~3.121ppm place is structural unit " RS-CH 2 -CH 2 The proton absorption peak on the carbon nucleus linked to the sulfur atom in -Si-"; the triplet peak that appears at δ=2.887-2.906ppm is the structural unit "HOOC-CH 2 The proton absorption peak on the carbon nucleus conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com