Sewing machine transmission structure

A technology of transmission structure and sewing machine, which is applied in the direction of sewing machine ring mechanism, sewing machine components, sewing machine control device, etc. It can solve the problems of large overall structure size and unsuitable processing, and achieve small overall structure size, simple processing, and transmission The effect of less bite resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

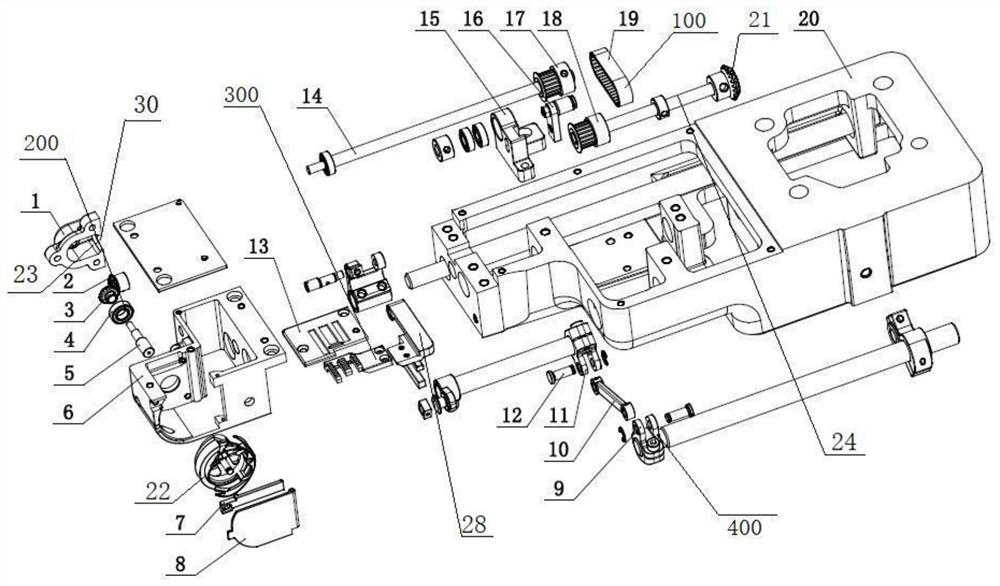

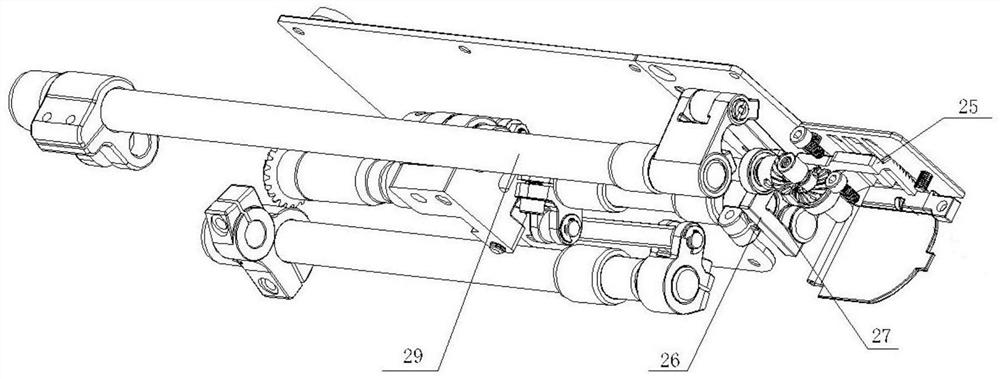

[0027] like figure 1 , figure 2 Shown; A kind of sewing machine transmission structure provided by the present invention comprises: gear cover 1, belt transmission mechanism 100, hook mechanism 200, crimping mechanism 300, crank transmission mechanism 400, machine base 20 and needle plate 13; The transmission mechanism includes a lower shaft 14 and a first main transmission shaft 24; the first synchronous wheel 17 parallel to it is equipped with one end of the lower shaft; the first rotary hook gear 21 is equipped with one end of the first transmission main shaft, and The second synchronous wheel 18; the first rotary hook gear is used to drive and connect the power unit of the machine head, and the driving of the power unit of the machine head drives the first transmission main shaft to rotate, and the first synchronous wheel is connected to it by a synchronous belt transmission. The second synchronous wheel; the end of the lower shaft away from the first synchronous wheel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com