Connecting structure of precast pile and bearing platform and construction method

A technology for connecting structures and construction methods, which is applied in basic structure engineering, construction, etc., and can solve the problem of insufficient connection between steel bars and longitudinal reinforcement at the bottom of caps, problems with connection and construction methods in engineering design, and cracking and damage at the joints between prefabricated piles and caps and other problems, to achieve the effect of simple and fast connection, easy quality assurance and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

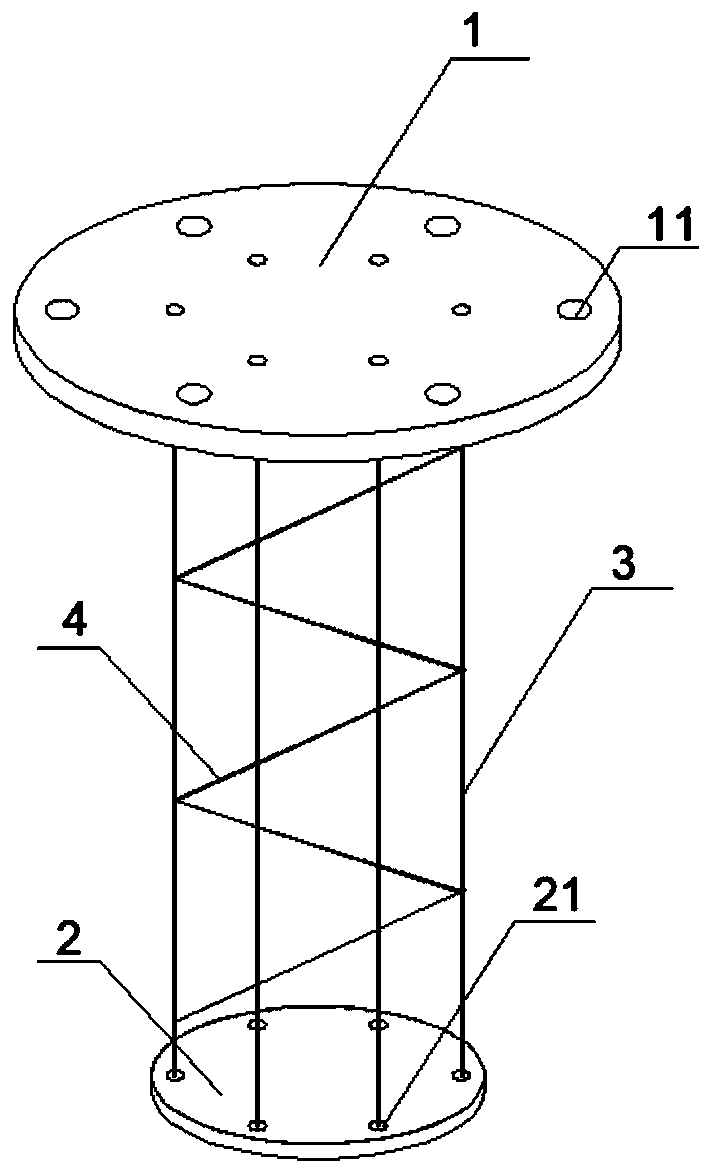

[0024] see figure 1 , this embodiment provides a connection structure between a prefabricated pile and a cap, including an upper end plate 1 and a lower end plate 2 with the same central axis, and the upper end plate 1 and the lower end plate 2 are connected by a number of main bars 3. This embodiment The cross-sections of the upper and lower end plates 1 and 2 are both circular, and the radius of the upper end plate 1 is larger than that of the lower end plate 2 , that is, the cross-section of the upper end plate 1 can cover the cross-section of the lower end plate 2 .

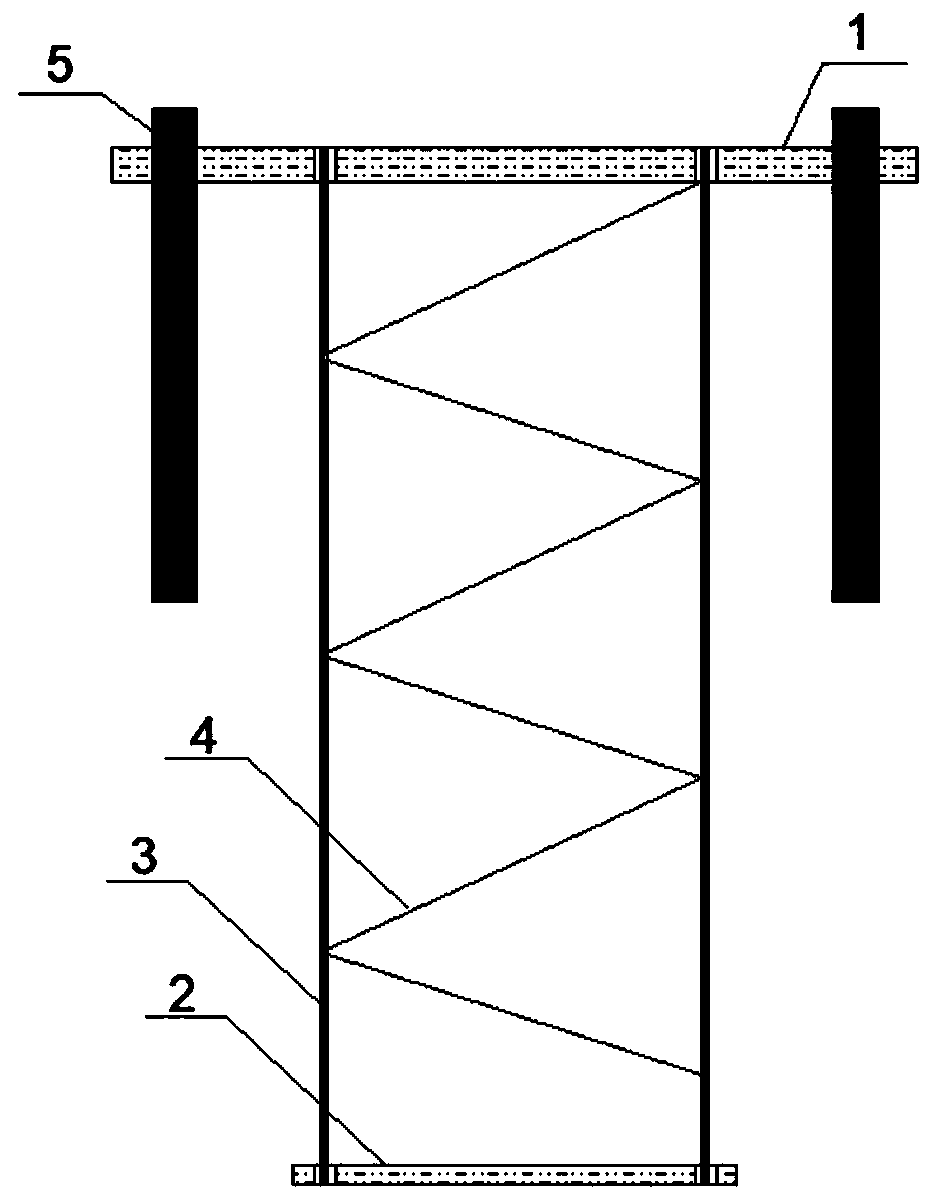

[0025] see figure 2 and combine figure 1 , a number of main ribs 3 are vertically arranged along the circumferential direction of the lower end plate 2, the top end of the main ribs 3 is connected to the upper end plate 1, the corresponding main rib holes 21 are arranged in the upper end plate 1 and the lower end plate 2, and the two ends of the main rib 3 are connected to the main rib holes 21, Stirrups 4...

Embodiment 2

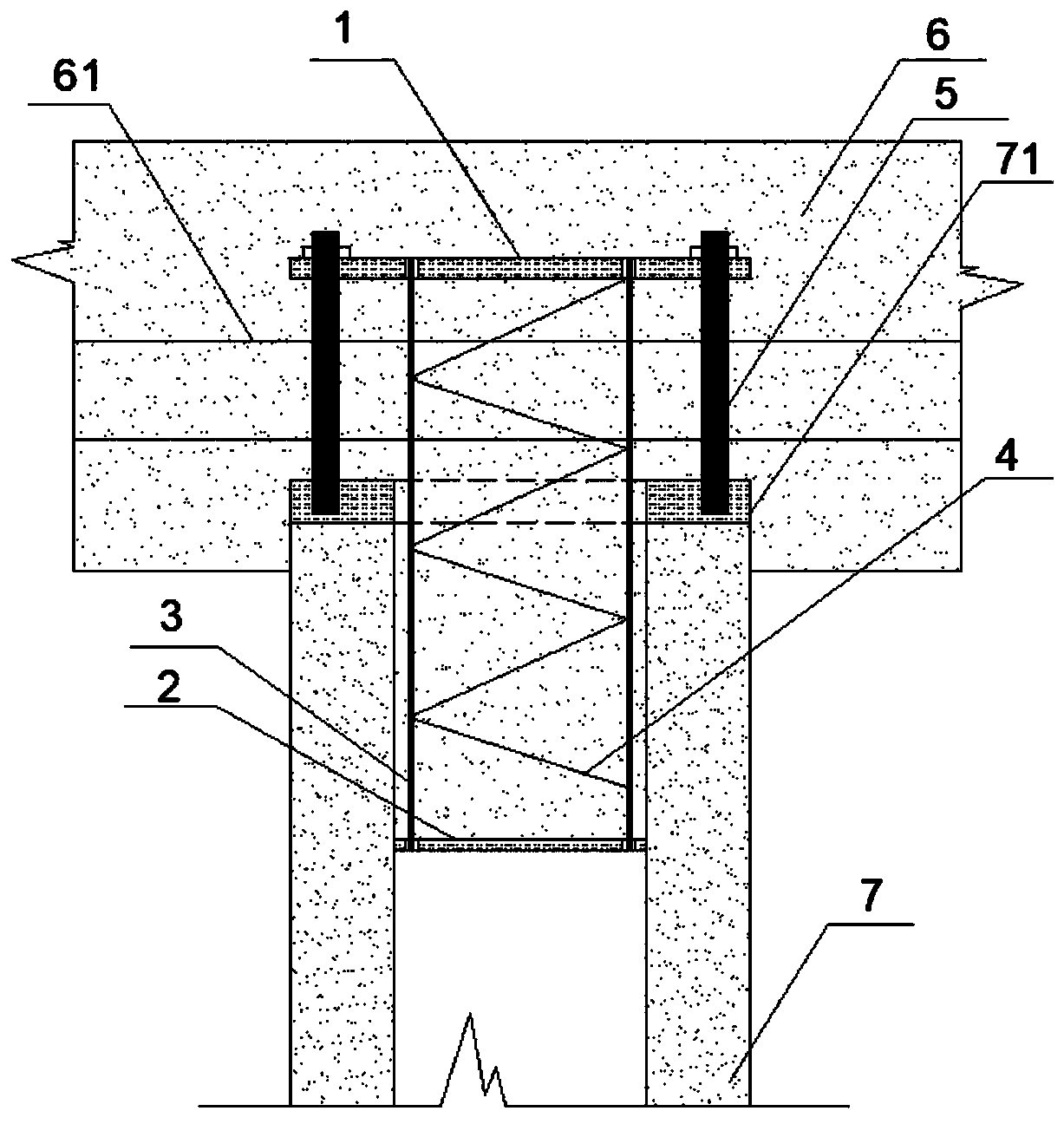

[0028] On the basis of Embodiment 1, in this embodiment, the prefabricated pile 7 to be connected is preferably a hollow cylindrical structure, and the two ends of the prefabricated pile 7 are provided with corresponding prefabricated pile end plates 71 of annular structure, and the corresponding upper end plate 1 and the lower end plate 2 are both circular in cross section, the lower end plate 2 is adapted to the hollow cavity of the prefabricated pile 7 , and the outer diameter of the upper end plate 1 is greater than or equal to the outer diameter of the prefabricated pile end plate 71 .

[0029] see image 3 and Figure 4 , the present embodiment provides a construction method for the connection structure of a prefabricated pile and a cap, comprising the following steps:

[0030] Step (1), preprocessing

[0031] Remove the foundation soil around the prefabricated pile 7, make the pile top of the prefabricated pile 7 reach the design elevation, and be 20cm~40cm higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com