Method for removing cleavage rupture membrane for decoking and oil removal on surface of Alfalava plate heat exchanger

A technology of plate heat exchanger and bursting membrane, which can be used in the petroleum industry, processing hydrocarbon oil, cleaning heat transfer devices, etc., and can solve problems such as coking and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific examples, but the present invention is not limited to the specific examples.

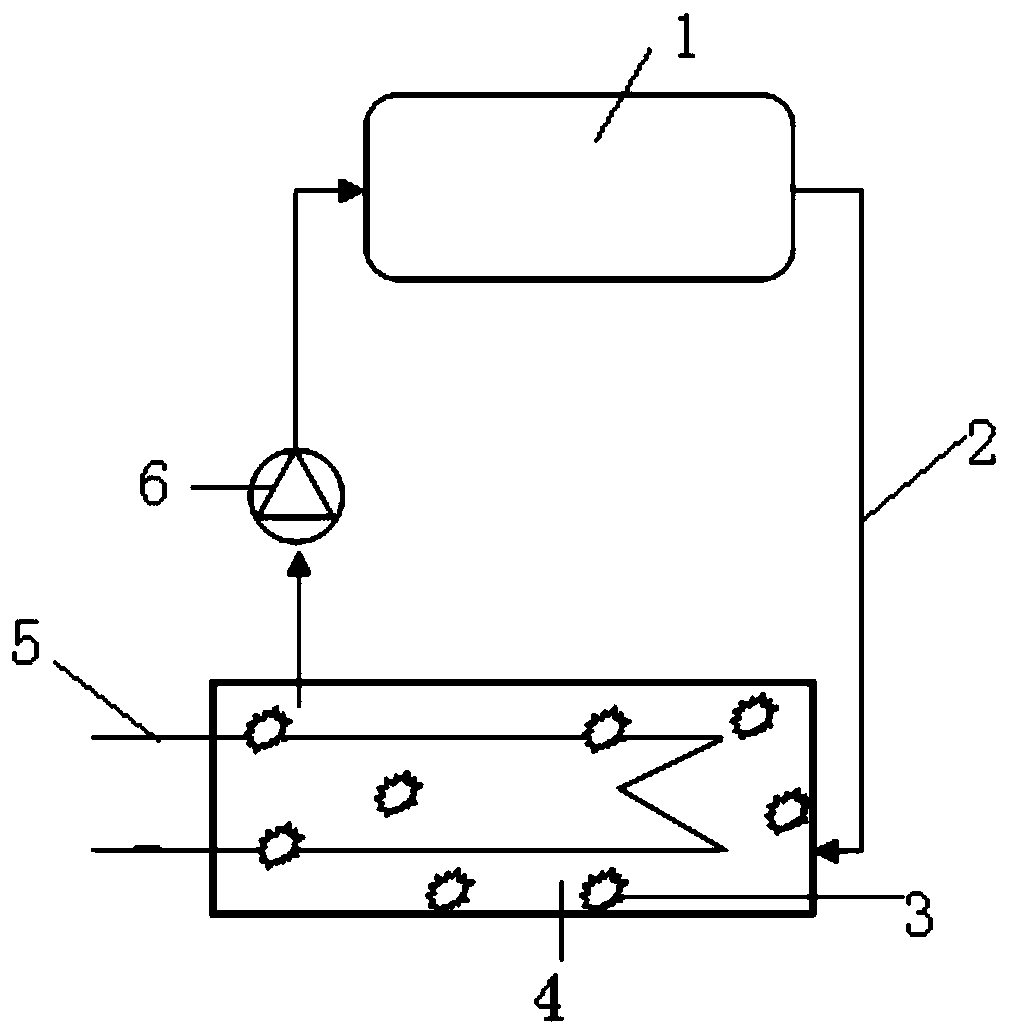

[0030] Such as figure 1 As shown, when the plate heat exchanger 1 is not disassembled, connect the stainless steel pipeline 2, the 316L stainless steel horizontal single-stage centrifugal pump 6 and the 10 cubic stainless steel reactor 4 with the steam heater 5 to form a closed operation system, in which the 316L stainless steel horizontal The single-stage centrifugal pump is equipped with a motor of 75kw, a lift of 80 meters, and a rotation speed of 1450r / min. After the sealed operation system is connected with the plate heat exchanger, a set of plate heat exchanger-plate heat exchanger external circulation closed operation reaction system is formed; Test run, check for leaks;

[0031] When there is no leak point, use hot water to heat up to 80°C, and add plant enzyme reactant 3; add plant enzyme reactant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com