Cleaning method of energy mixing heat exchange unit with pipeline online flushing function

A technology for heat exchange units and pipes, which is used in flushing, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of reduced equipment life, cumbersome work, and high costs, so as to improve flushing efficiency, solve cumbersome work, and avoid equipment. The effect of life loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

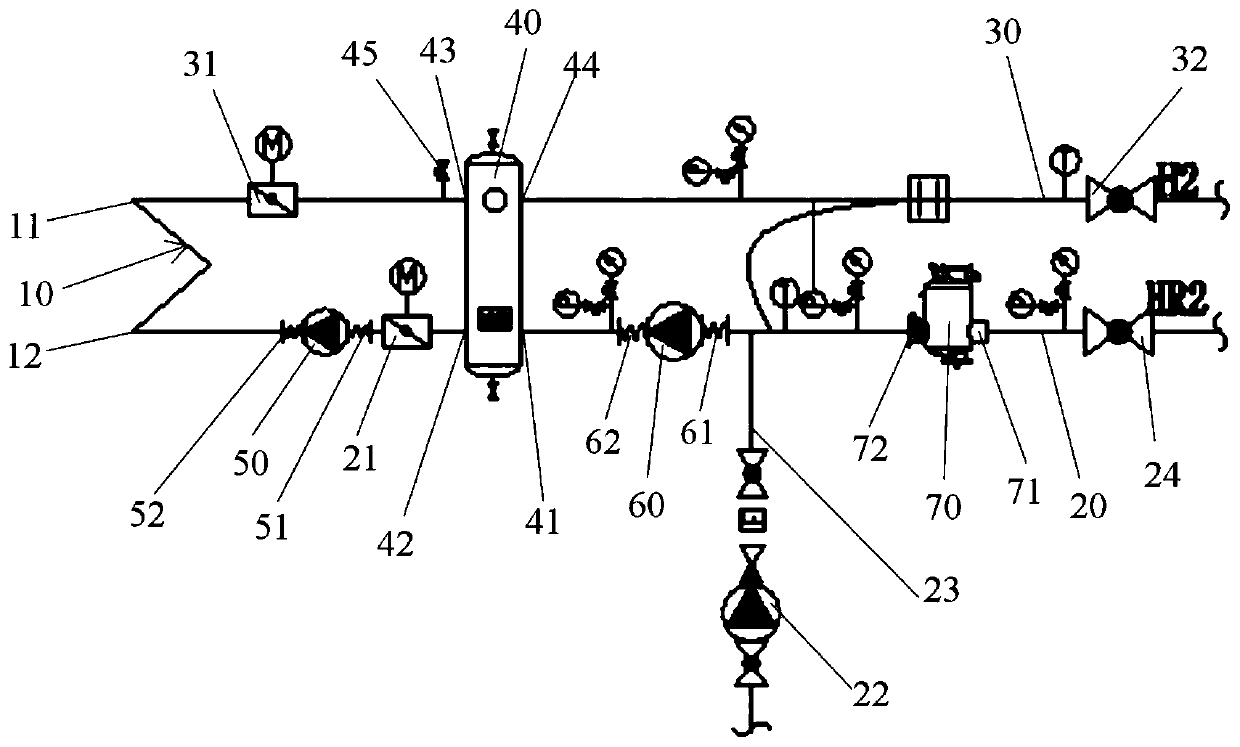

[0016] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

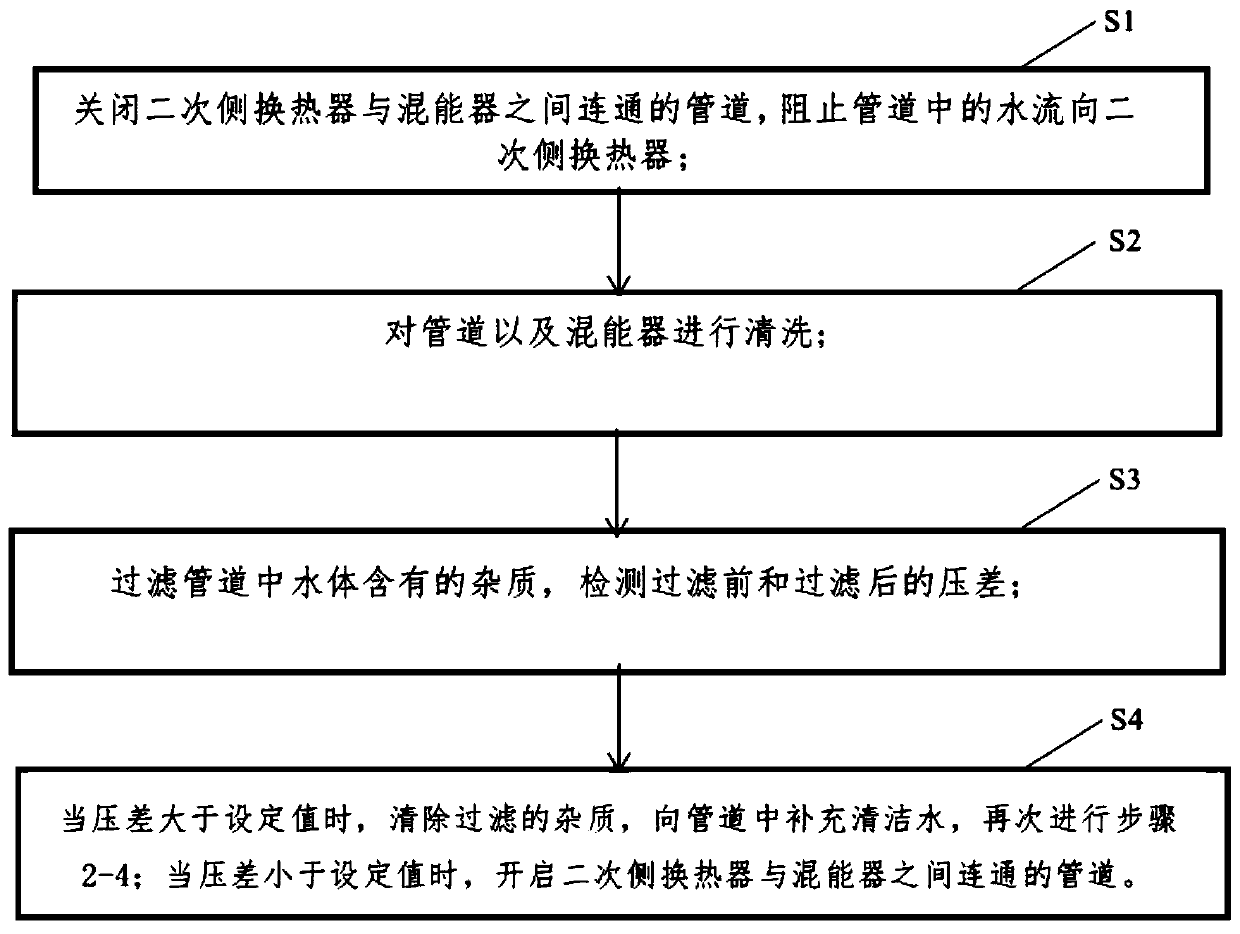

[0017] Such as figure 1 As shown, a cleaning method of a hybrid heat exchanger unit with pipeline online flushing function, the hybrid heat exchanger unit includes a secondary side heat exchanger and a mixer connected in parallel with the secondary side heat exchanger, the The cleaning method includes the following steps:

[0018] S1: Close the pipeline connecting the secondary side heat exchanger and the mixer to prevent the water in the pipeline from flowing to the secondary side heat exchanger;

[0019] S2: cleaning the pipeline and mixer;

[0020] S3: Filter the impurities contained in the water body in the pipeline, and detect the pressure difference before and after filtration;

[0021] S4: When the pressure difference is greater than the set value, remove the filtered impurities, add clean water to the pipeline, and perform steps 2-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com