Turbojet engine pressure measurement and diagnosis method and device

A turbojet engine and diagnostic method technology, applied in the fields of engine control, turbojet engine pressure measurement and fault diagnosis, can solve the problems of unrecognizable signal acquisition faults, increased redundancy design, poor reliability, etc., to avoid system complexity , high reliability, and realize the effect of diagnostic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

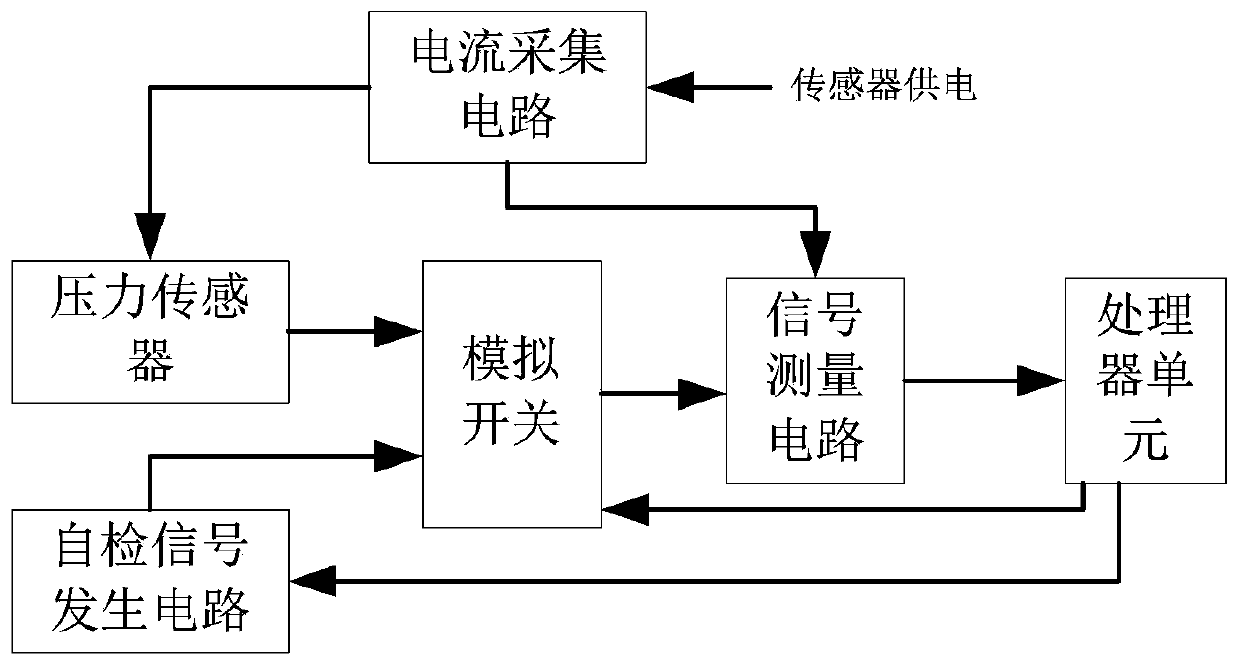

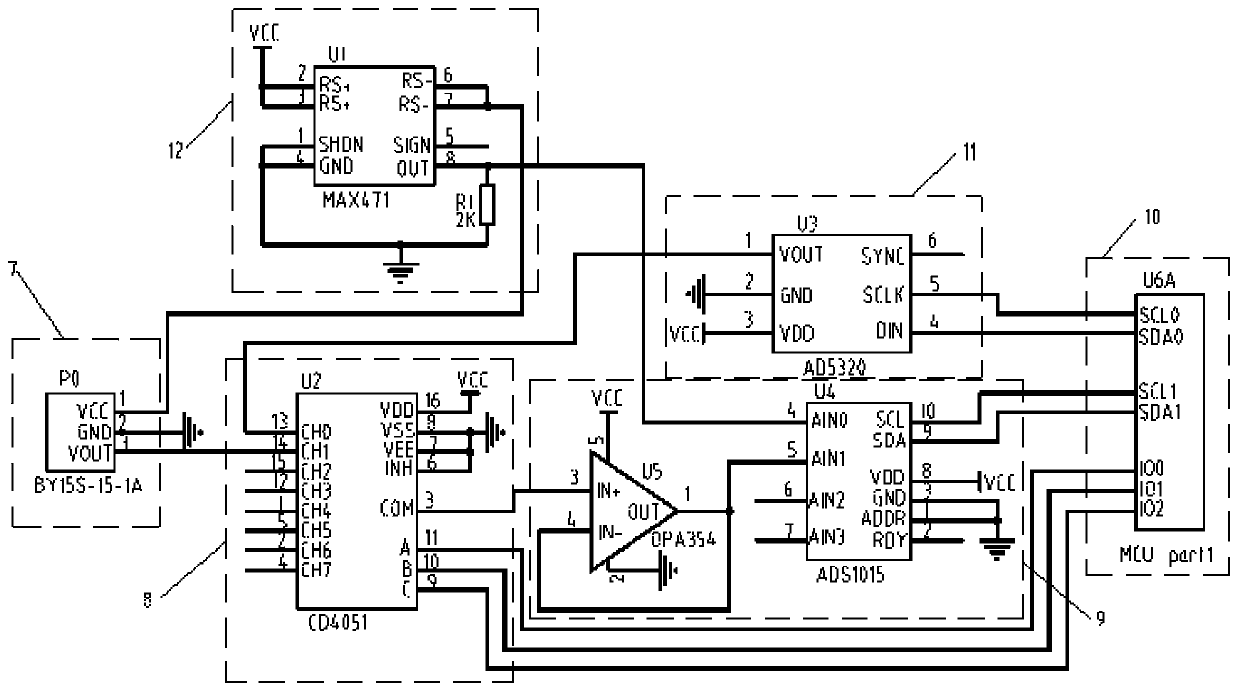

[0033] A kind of turbojet engine pressure measuring and diagnosing device that the preferred embodiment of the present invention provides, such as figure 1 As shown, it includes a pressure sensor for detecting the pressure signal of each detection point of the turbojet engine, and also includes an analog switch. The signal output terminals of each detection point pressure sensor are respectively connected to each signal channel of the analog switch, and one signal channel of the analog switch is also connected to The self-test signal generation circuit, the analog switch signal output end is connected with a signal measurement circuit that converts the pressure signal or self-test signal into a digital signal, the output end of the signal measurement circuit is connected to the processor, and the power supply circuit of the pressure sensor is also equipped with a current acquisition circuit. circuit, the current acquisition circuit collects the working current and converts it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com