Device and method for testing turning diameter of superconducting strip

A technology of superconducting strip and turning diameter, applied in electromagnetic measuring device, superconducting performance measurement, electric/magnetic diameter measurement, etc., can solve the problem that the critical current cannot deduce the critical turning diameter of the strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

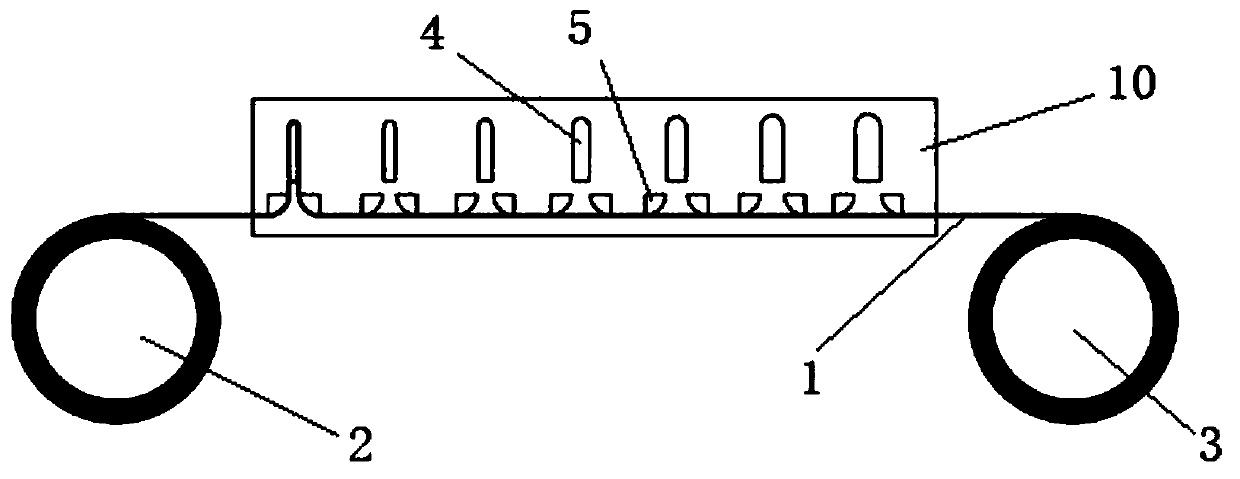

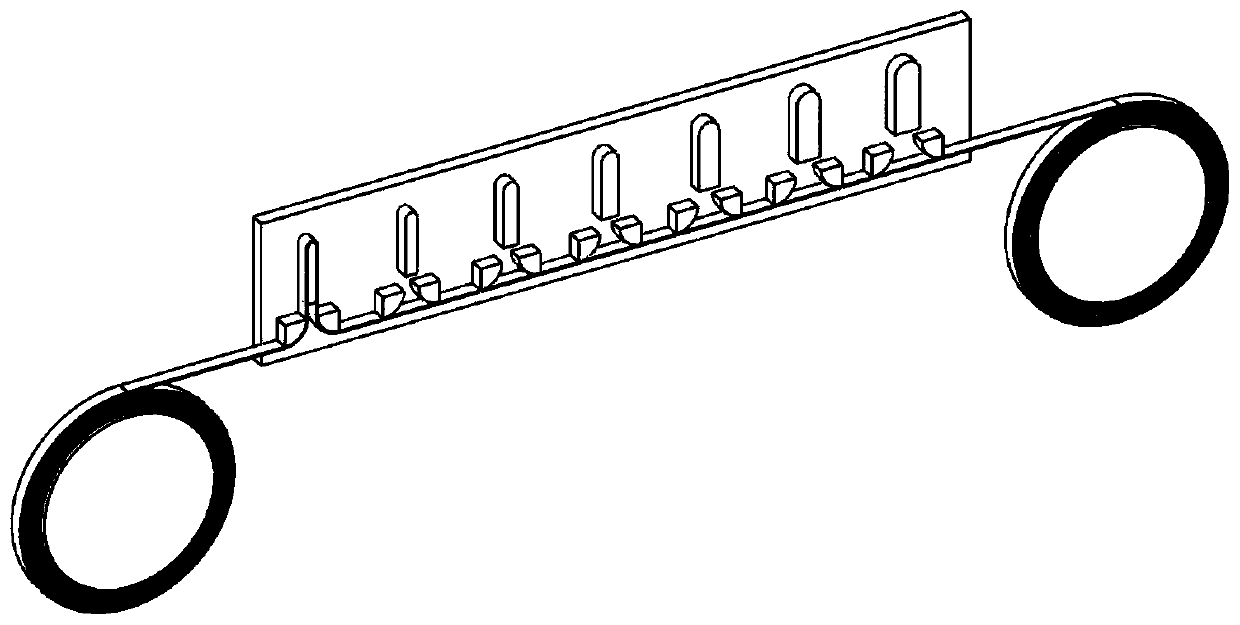

[0044] Such as figure 1 with figure 2 As shown, the device for testing the turning diameter of a superconducting strip provided in this embodiment includes: a strip discharge end 3, a strip receiving end 2 and a turning diameter test board 10. A plurality of bending diameter test blocks 4 and a plurality of guide blocks 5 are provided on the turning diameter test board 10. Each bending diameter test block 4 has a different bending diameter. The bending diameter test blocks 4 are arranged in a row from small to large according to their respective bending diameters. Each bending diameter test block 4 corresponds to two guide blocks 5. The two guide blocks 5 are located on the left and right sides below the corresponding bending diameter test block 4.

[0045] Specifically, the overall surface roughness of the bending diameter test block 4 is less than Ra1.6, and the top has an arc surface, and the corresponding bending diameter is provided by the arc surface of itself, so that the...

Embodiment 2

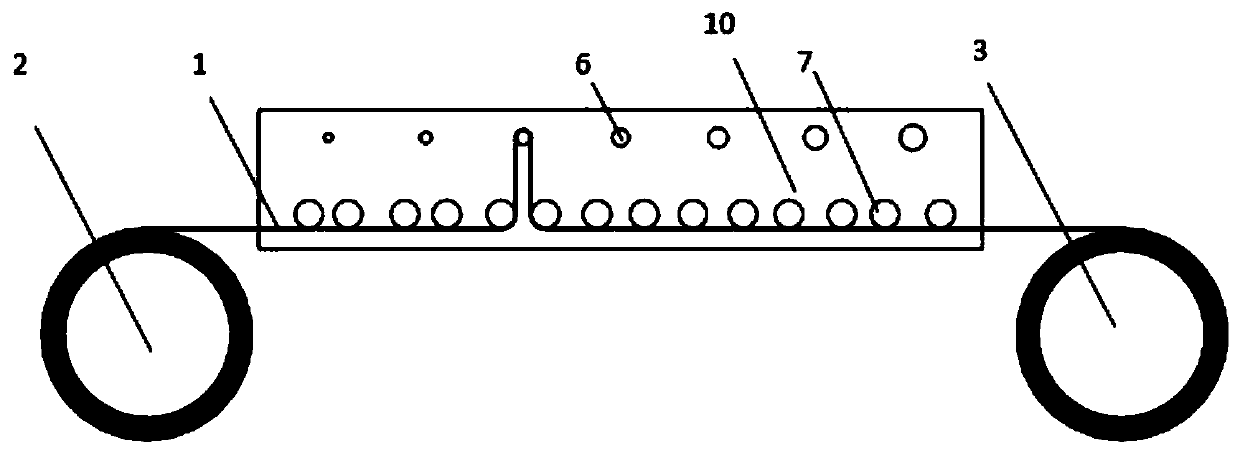

[0048] Such as image 3 with Figure 4 As shown, the device for testing the turning diameter of a superconducting strip provided in this embodiment includes: a strip discharge end 3, a strip receiving end 2 and a turning diameter test board 10. A plurality of bending diameter test wheels 6 and a plurality of guide wheels 7 are provided on the turning diameter test board 10. Each bending diameter test wheel 6 has a different bending diameter. The bending diameter test wheels 6 are arranged in a row from small to large according to their respective bending diameters. Each bending diameter test wheel 6 corresponds to two guide wheels 7. The two guide wheels 7 are located at the left and right sides below the corresponding bending diameter test wheel 6.

[0049] Specifically, the overall surface roughness of the curved diameter test wheel 6 is less than Ra1.6, and the corresponding curved diameter is provided by the curved surface of itself to bend the superconducting strip 1 to be t...

Embodiment 3

[0052] Such as Figure 5 with Image 6 As shown, the device for testing the turning diameter of a superconducting strip provided in this embodiment includes: a strip discharge end 3, a strip receiving end 2 and a turning diameter test board 10. A plurality of bending diameter test wheels 8 are provided on the turning diameter test board 10.

[0053] Every two bending diameter test wheels 8 form a group, and different groups of bending diameter test wheels 8 have different bending diameters. In this embodiment, two bending diameter test wheels 8 with the same bending diameter are placed on the left and right, so that multiple sets of bending diameter test wheels 8 are arranged in two rows according to the bending diameter from small to large. Among them, the left and right rows can be placed up and down to avoid friction damage to the superconducting strip 1 to be tested.

[0054] Specifically, the overall surface roughness of the bending diameter test wheel 8 is less than Ra1.6, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com