High-temperature superconducting cable coiling machine and cable coiling method

A high-temperature superconducting and winding machine technology, which is applied in the direction of superconducting devices, cable/conductor manufacturing, and the usage of superconducting elements, can solve the problems of brittle fracture of superconducting thin sheets, cable damage, easy distortion and deformation, etc., to achieve Easy winding operation, uniform pay-off tension and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

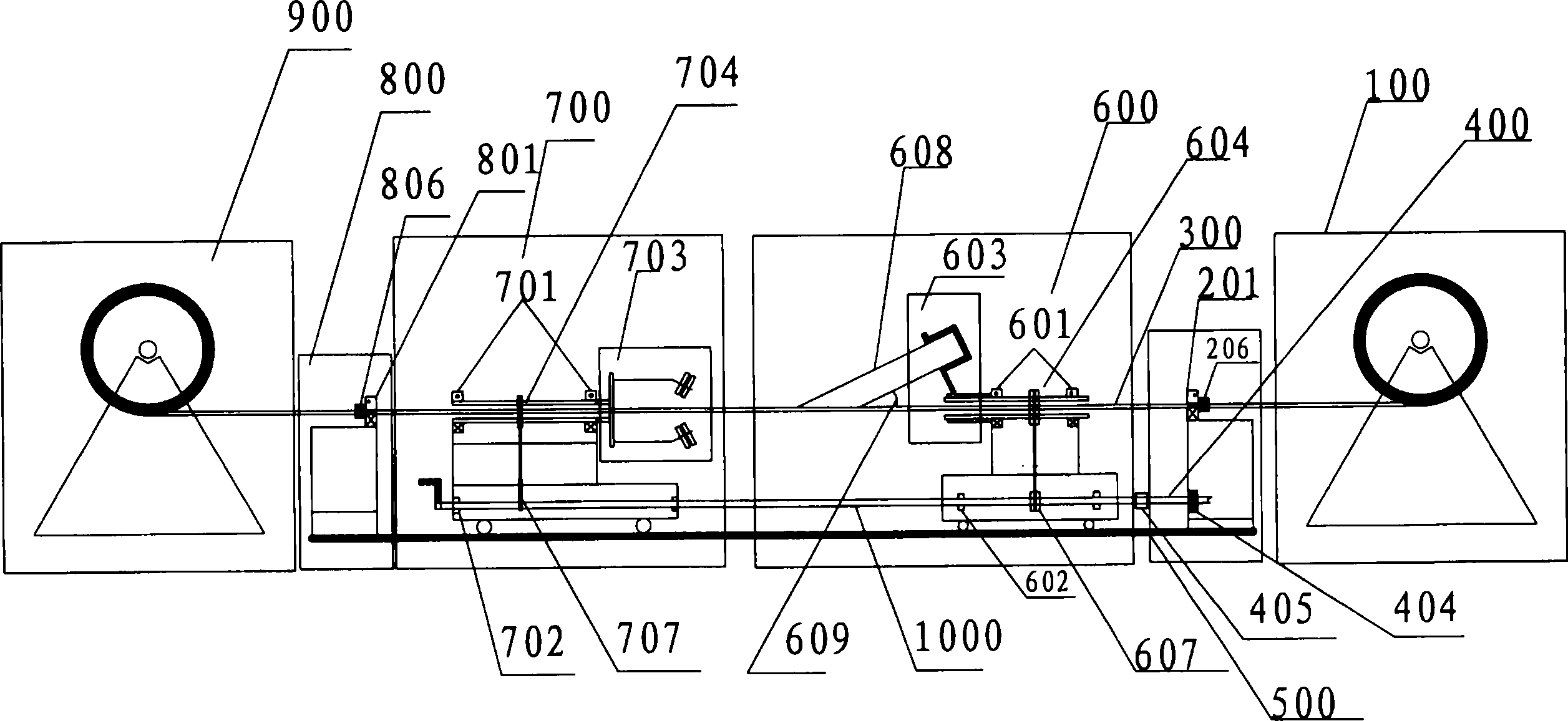

[0030] Such as figure 1 As shown, the high temperature superconducting tape winding machine of the present invention mainly includes guide rail 500, rear support frame 200 for fixing ball screw 400 and superconducting cable, front support frame 800 for fixing cable, insulating tape wrapping car 700 and superconducting cable Conductive tape winding car 600 and other five parts.

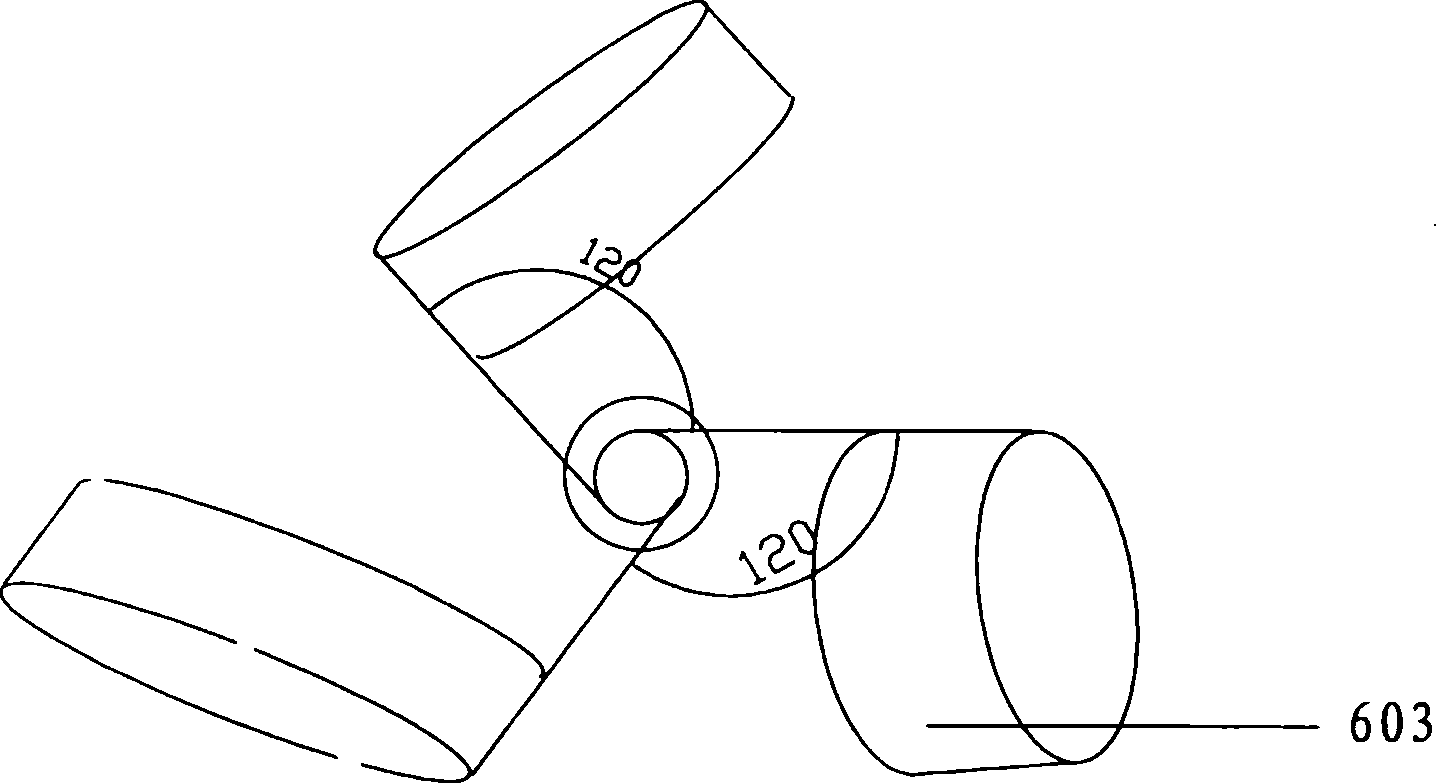

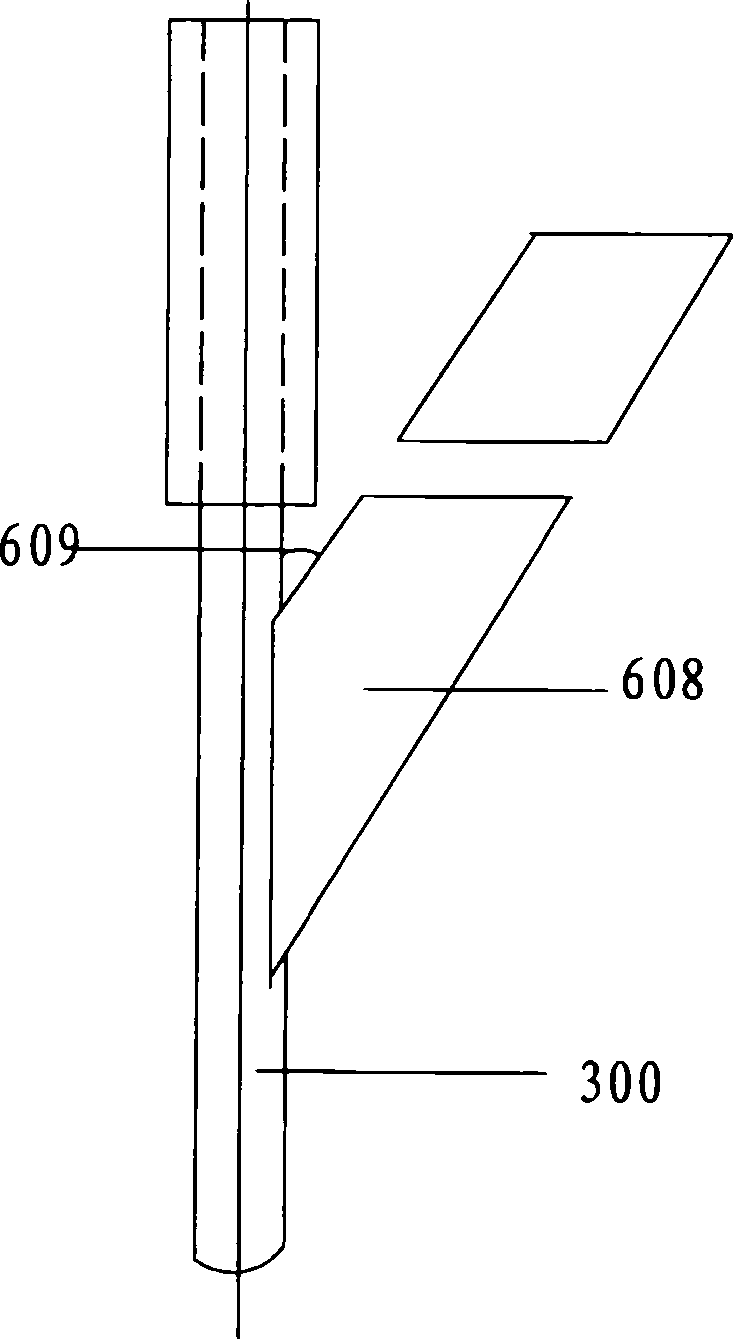

[0031]The insulating tape wrapping car 700, the high temperature superconducting strip winding car 600, the rear support frame 200, and the upper part of the front support frame 800 are respectively equipped with φ50 ball bearing support seats 201, 601, 701, 801. The hollow shaft 604 of phi 50 * 1.5 is housed in the middle of two 601 and two 701 ball bearing supports, and tetrafluoroethylene protective cover is housed in 201,801 ball bearing supports. The cable ske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com