Secondary anti-retreating structure of terminal

A terminal and housing technology, which is applied in the field of secondary anti-return structure of terminals, can solve the problems of increased contact resistance of connectors, protruding contact pieces, ablation of connectors, etc., and achieves reliable functions, simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure and characteristics of the secondary anti-retraction structure of the terminal proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. And its effect, detailed description is as follows.

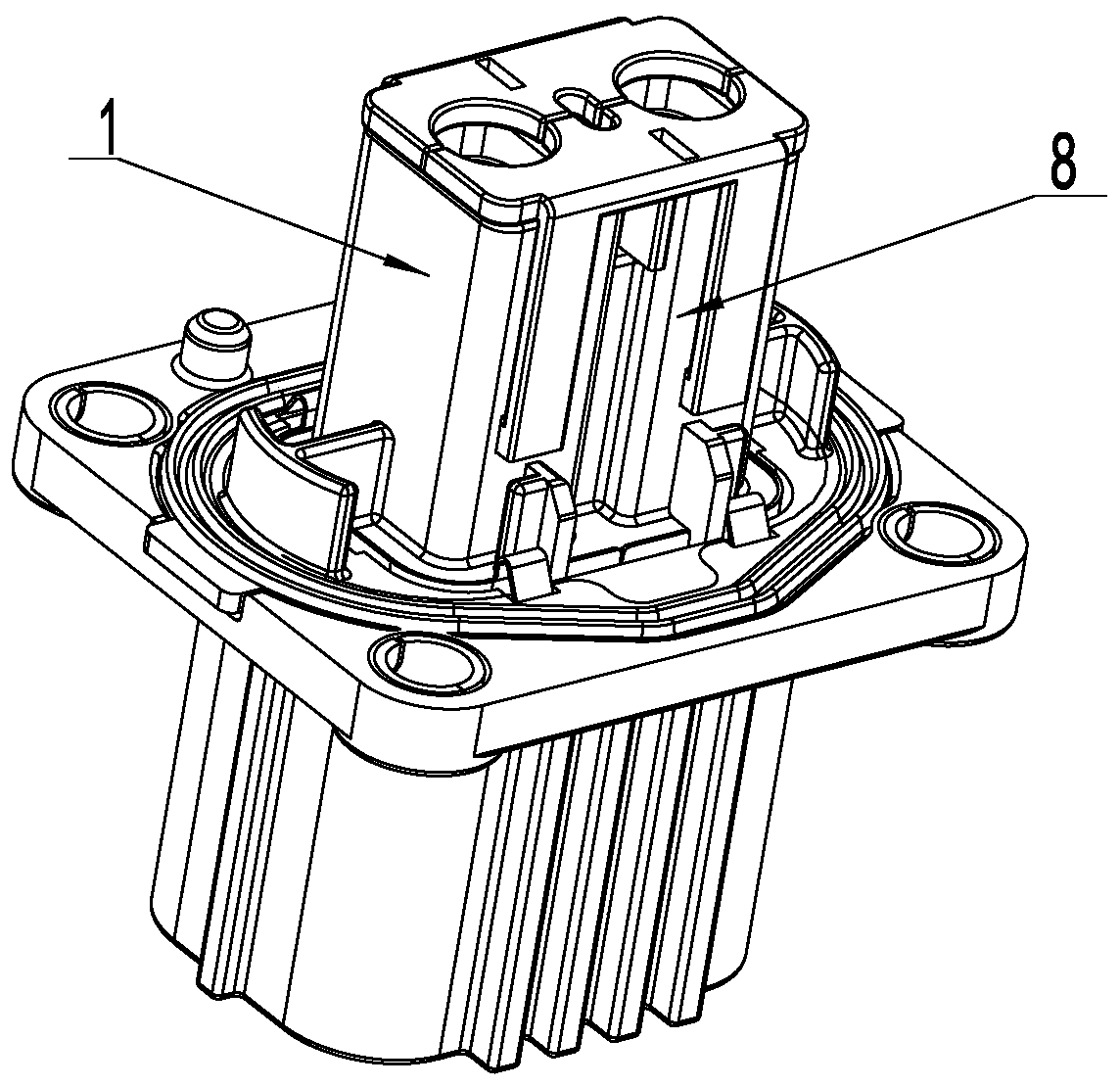

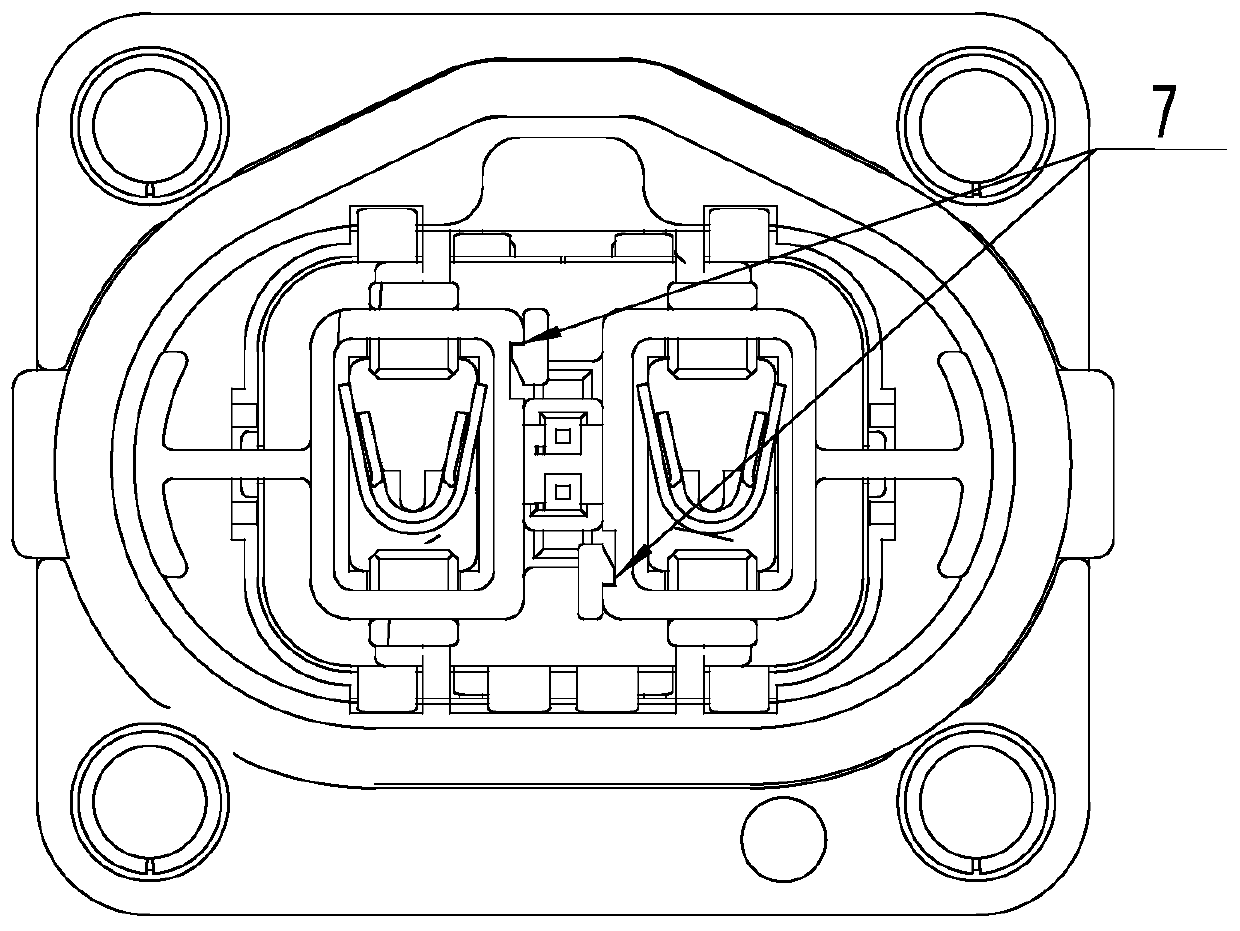

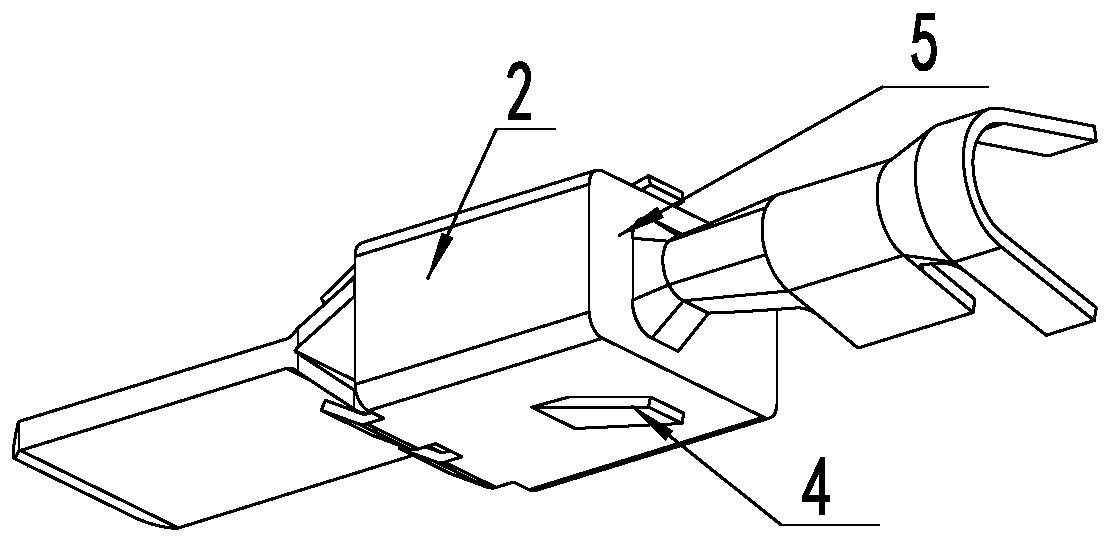

[0035] see Figure 1-8 , which is a structural schematic diagram of each part of the secondary anti-retraction structure of the terminal of the present invention, including a housing 1, which is equipped with a contact piece 2, and the contact piece 2 is connected to the housing through the positioning claws provided on both sides. The stop fit of the inner step surface of 1 realizes the one-time positioning of the contact piece, and prevents the contact piece 2 from retreating and coming out.

[0036] Two positioning steps 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com