Gas generator and assembly method for dual-type gas generator

A technology of gas generators and gas generating agents, which is applied in the fields of weapon accessories, transportation and packaging, and vehicle safety arrangements, and can solve problems such as pulverization of gas generating agents, sound generation, and changes in combustion characteristics of gas generating agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

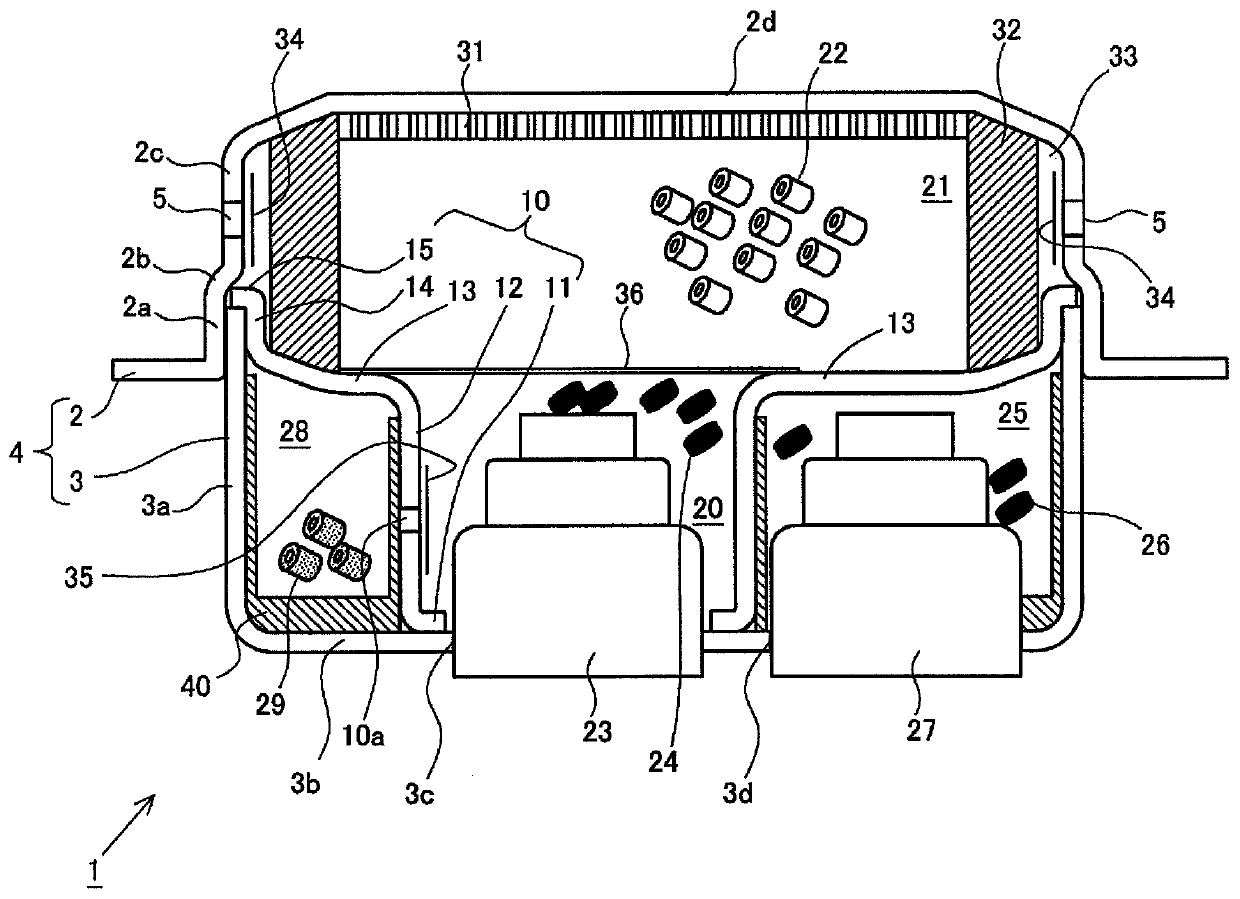

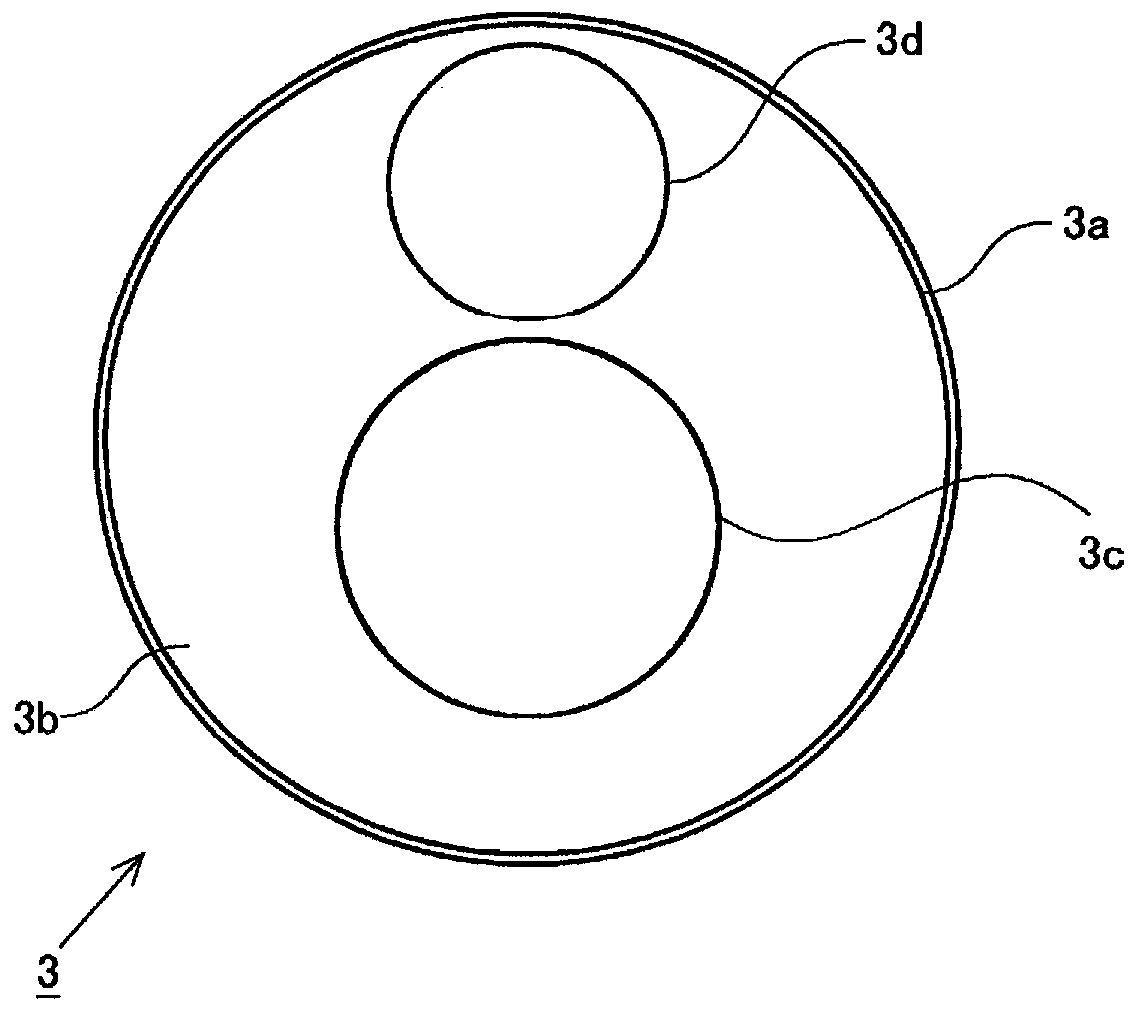

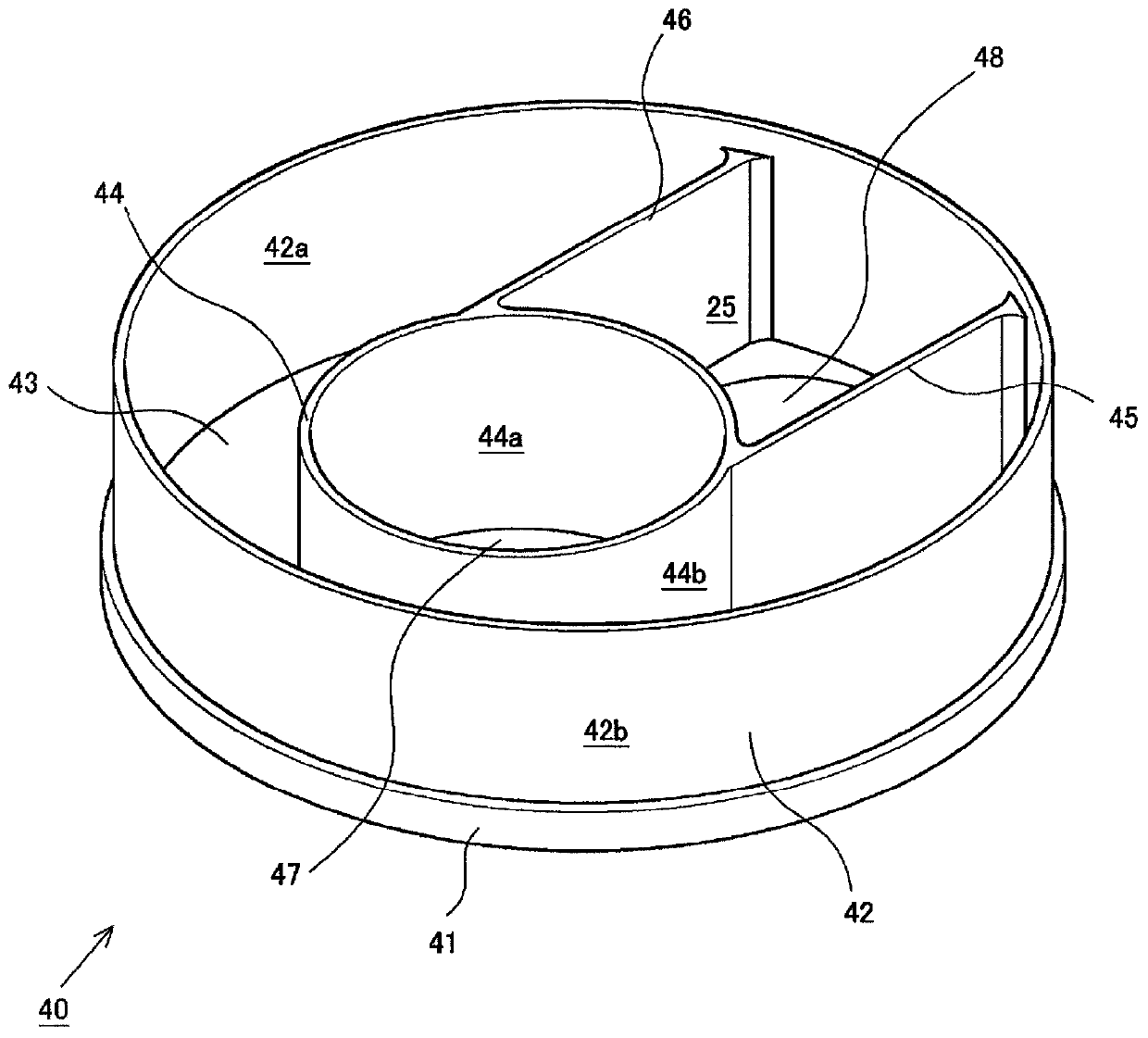

[0066] figure 1 is a cross-sectional view of the gas generator 1 in the height direction, figure 2 It is a plan view of the lower case 3 (second case) included in the gas generator 1 . The gas generator 1 is configured to burn a gas generating agent filled in a casing 4 formed of an upper casing 2 (first casing) and a lower casing 3 to release combustion gas. The gas generator 1 is a so-called two-stage gas generator in which two combustion chambers are arranged vertically as described later, and a corresponding igniter and a gas generating agent are arranged in each combustion chamber. Here, the upper case 2 has a peripheral wall portion 2c and a top portion 2d, and a concave internal space is formed by these. The top surface portion 2d and the bottom surface portion 3b of the lower case 3 described later have a substantially circular shape in plan view, and the peripheral wall portion 2c and the peripheral wall portion 3a of the lower case 3 described later surround the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com