Three-jaw chuck with adjustable auxiliary supporting structure and using method for three-jaw chuck

A three-jaw chuck and auxiliary support technology, which is applied in the direction of chucks, tool holder accessories, metal processing equipment, etc., can solve the problems of insufficient rigidity in the cutting area, increase the rigidity of the cutting area, and deformation of parts during processing, so as to improve cutting conditions. , multi-cutting force, and stable cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

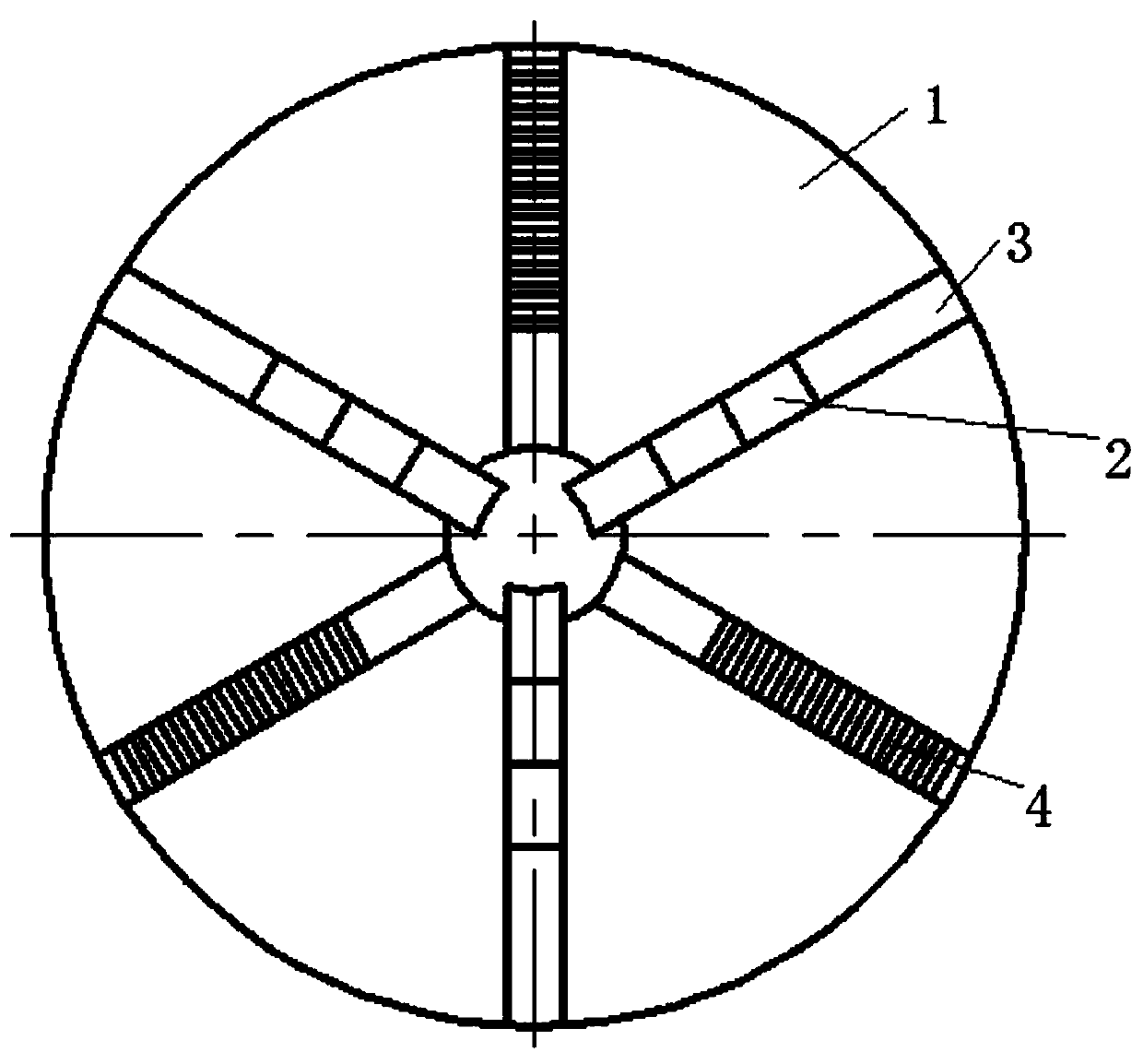

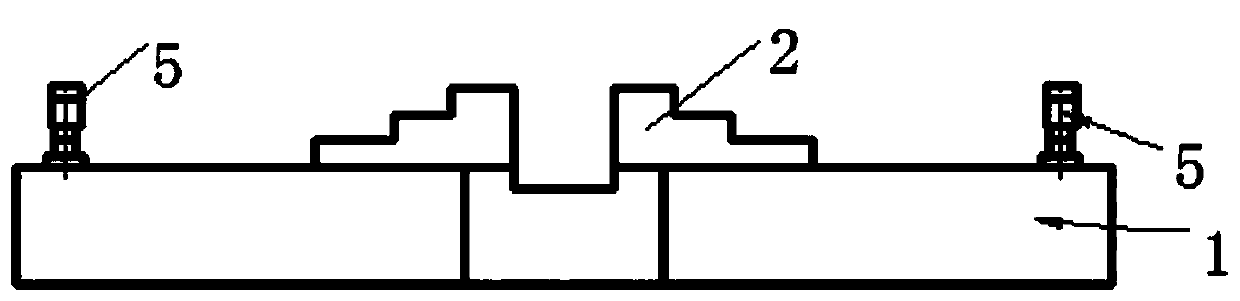

[0037] refer to figure 1 and figure 2 , is a structural schematic diagram of Embodiment 1 of the present invention, a three-jaw chuck with an adjustable auxiliary support structure, which is characterized in that it includes:

[0038] The chuck body 1 has a chuck hole in the middle center of the chuck body 1;

[0039] There are three soft-jaw slots 3 along the chuck hole in the center of the chuck body 1, and the three soft-jaw slots 3 are evenly distributed on the upper surface of the chuck body 1;

[0040] The soft jaw 2 is detachably connected in the soft jaw slot 3 along the chuck hole;

[0041] The support column tooth groove 4, the support column tooth groove 4 is arranged between two adjacent soft claw slots 3, and there are three support column tooth grooves 4;

[0042] The support column 5 is detachably connected in the support column tooth groove 4 .

[0043] In actual use: put the machined part into the chuck hole at the center of the middle of the chuck body 1...

Embodiment 2

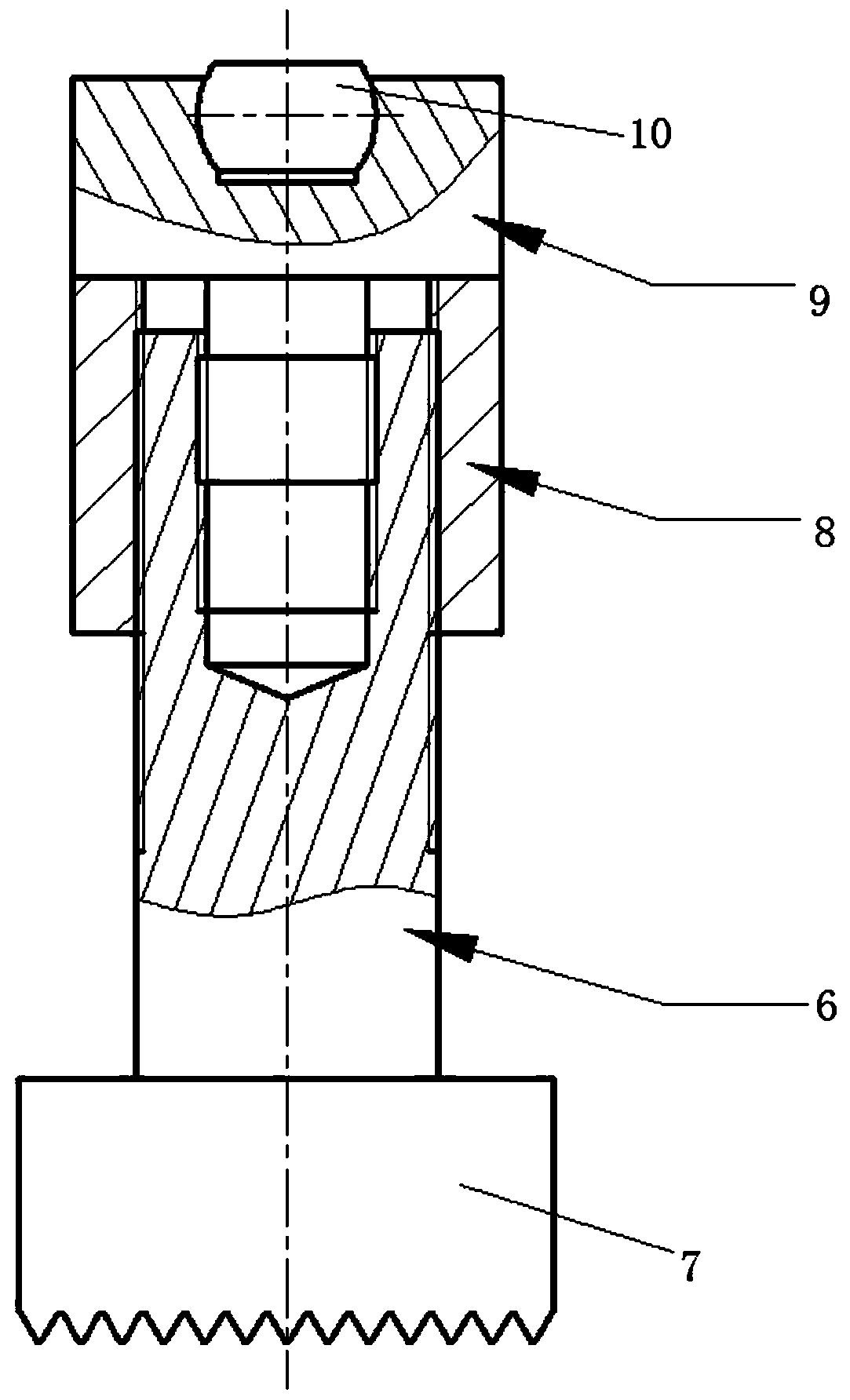

[0045] refer to image 3 , Compared with Embodiment 1, the difference of this embodiment is that: the support column 5 includes a support stud base 7, a support stud 6, a lock nut 8 and a support head 9, and the support stud 6 is connected to The top of the support stud base 7, the lock nut 8 is connected to the outer wall of the support stud 6, the support head 9 is connected to the top of the support stud 6, and the support head 9 is located above the lock nut 8, the support column tooth groove 4 Internal teeth are arranged inside, and the bottom of the support stud base 7 is connected in the support column tooth groove 4 .

[0046] In actual use: when adjusting the support column 5, first adjust the height of the support head 9 at the top of the support stud 6, and after determining the height of the support head 9, adjust the position of the support head 9 on the other two support columns 5. Adjust to make the processing surface of the processed parts level, and then scre...

Embodiment 3

[0048] Compared with Embodiment 2, the difference of this embodiment is that: the top of the support stud 6 has a threaded hole, the support head 9 is a screw-shaped structure, and the support head 9 is screwed on the support screw through the threaded hole. Top of column 6.

[0049] In actual use: when adjusting the support column 5, first adjust the height of the entire machined part by screwing the height of the screw-shaped support head 9 in the top threaded hole of the support stud 6, so as to adjust to the level of the machined surface of the machined part, use The height adjustment operation of the structure is simple, and the adjustment is convenient and fast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com