A pathological slicer

A pathological sectioning and slicing technology, applied in metal processing and other directions, can solve the problem of inability to serially section pathological tissues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

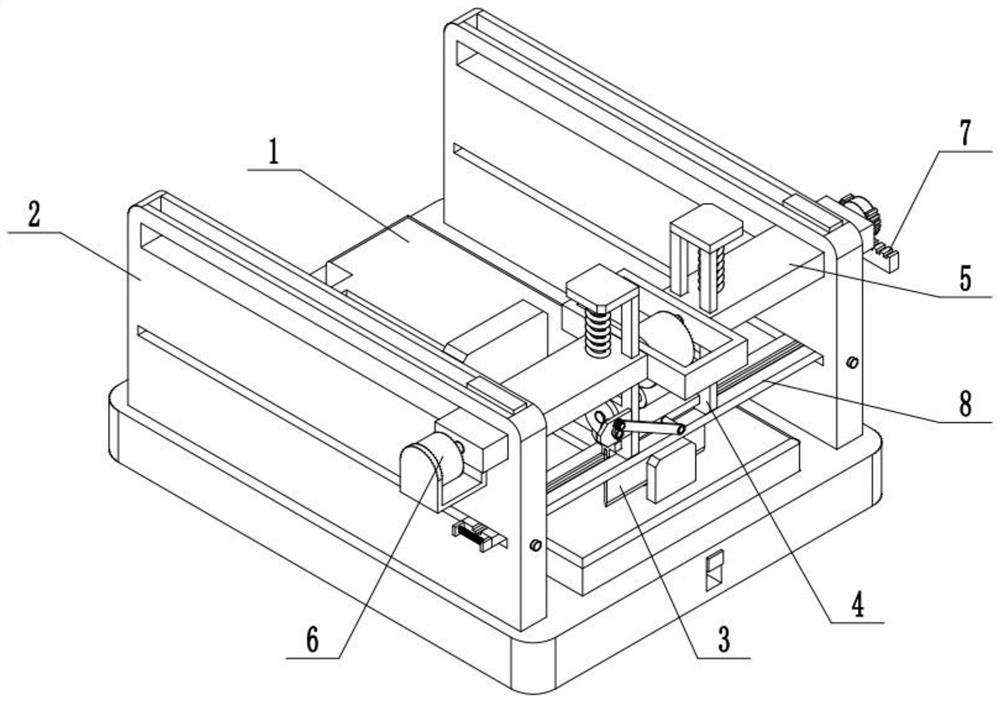

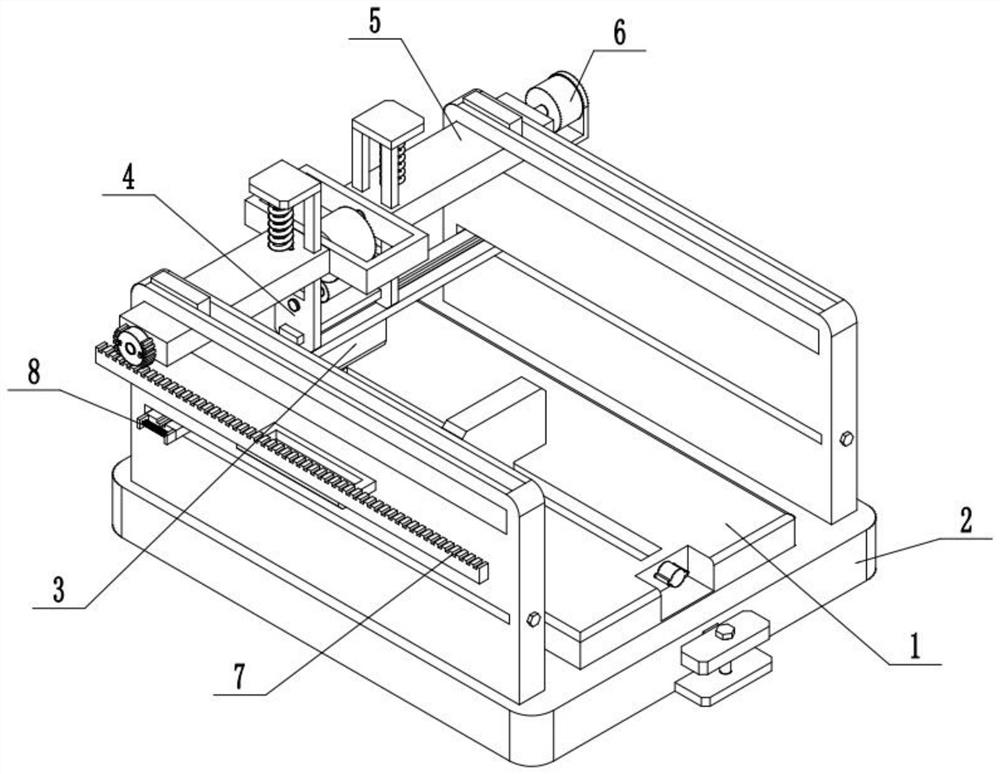

[0030] Such as Figure 1-10 As shown, a pathological slicing device includes a slicing platform 1, a complete machine support 2, a slice knife 3, a cutter seat 4, a sliding frame 5, a drive motor 6 and a straight rack 7, and the middle part of the complete machine support 2 is connected to There is a slicing platform 1; the slicing knife 3 is connected to the lower end of the cutter seat 4; the cutter seat 4 is connected to the sliding frame 5; the sliding frame 5 is slidably connected to the two ends of the whole machine support 2; the The drive motor 6 is connected to the sliding frame 5 through the motor seat; the drive motor 6 is connected to the cutter seat 4 in transmission; the cutter seat 4 is connected to the spur rack 7 in transmission; the spur rack 7 is fixedly connected to the frame of the whole machine 2 on.

[0031] A pathological slicing device of the present invention, when cutting a pathological tissue sample, after the pathological tissue sample is installe...

Embodiment 2

[0033] Such as Figure 1-10 As shown, the whole machine support 2 includes a base 201 and a side plate 202; two ends of the top surface of the base 201 are respectively fixedly connected to a side plate 202; the slicing platform 1 is connected to the base 201; the sliding frame 5 Slidingly connected to two side panels 202 .

Embodiment 3

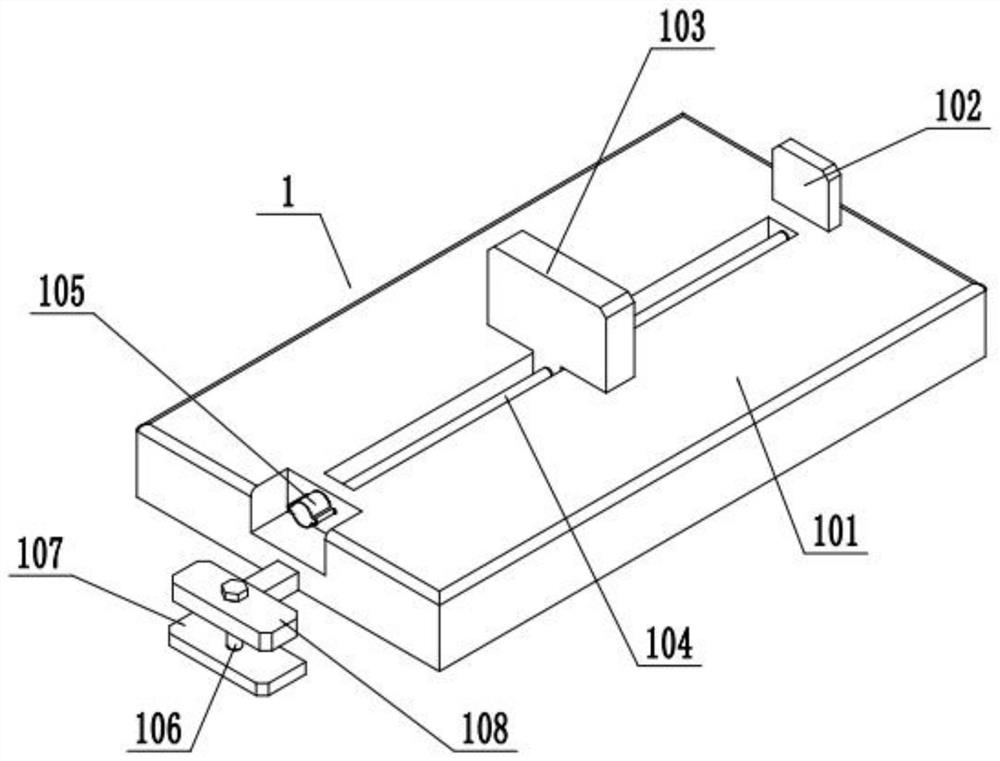

[0035] Such as Figure 1-10As shown, the slicing platform 1 includes a platform body 101, a fixed splint 102, a movable splint 103, a first screw 104, an adjustment rotary block 105, a second screw 106, a fixed plate 107 and a movable plate 108; the platform body 101 slides fit in the rectangular groove in the middle of the base 201; the fixed splint 102 is fixed on the front end of the top surface of the platform body 101; Connected to the first screw rod 104; the two ends of the first screw rod 104 are respectively rotated and matched with the two ends of the chute in the middle of the platform body 101; the rear end of the first screw rod 104 is fixedly connected to the adjusting block 105; The upper end of two screw rods 106 is threadedly connected on the movable plate 108; the rear end of the movable plate 108 is fixedly connected to the platform body 101; the lower end of the second screw rod 106 is rotatably fitted on the fixed plate 107; on the base 201. The slicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com