Multi-cavity aluminum profile mold

A technology for aluminum profiles and molds, applied in the field of multi-cavity aluminum profile molds, can solve problems such as mold explosion, mold damage, and production efficiency reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

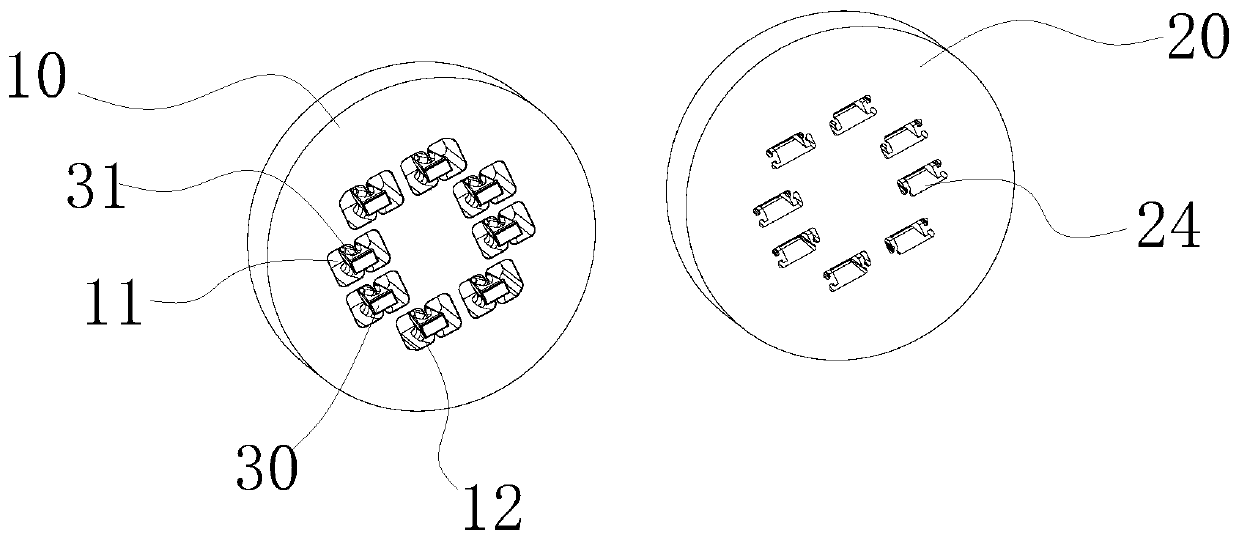

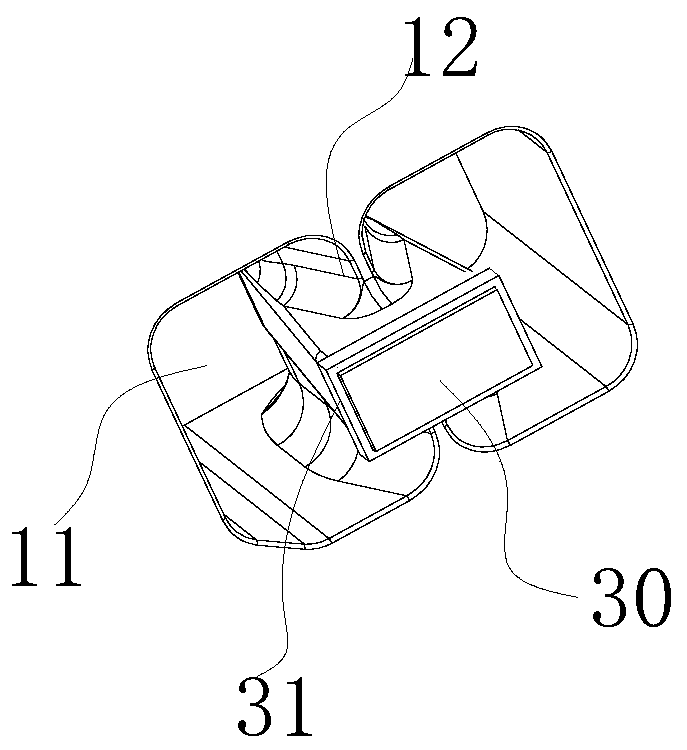

[0018] like Figure 1-4 As shown, a multi-cavity aluminum profile mold in this embodiment includes an upper mold 10 and a lower mold 20. The upper mold 10 is provided with a mold core 30 protruding from the material 10 and embedded in the lower mold 20. The above-mentioned upper mold 10 is provided with at least one feeding chamber 11, the feeding chamber 11 is divided into two parts by the splitter bridge 12, the mold core 30 is arranged on the splitter bridge 12, and the outer edge of the mold core 30 is close to the splitter bridge 12 From one end to the end away from the shunt bridge 12, the width gradually increases, and the width of the shunt bridge 12 close to the middle of the mold core 30 is greater than the width near the two ends of the feeding chamber 11;

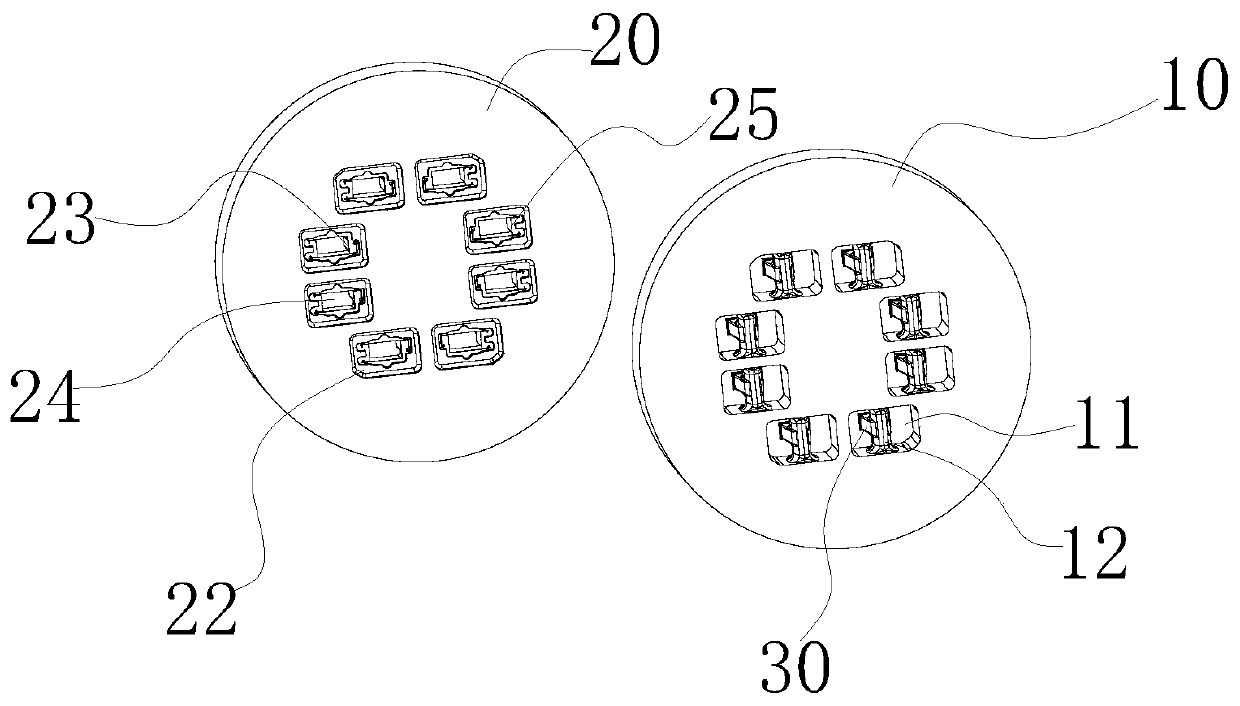

[0019] The upper mold 20 is provided with a welding chamber 22 on the lower mold 20 , the size of the welding chamber 22 is the same as that of the feeding chamber 11 , and a secondary welding chamber 23 is prov...

Embodiment 2

[0022] like figure 1 , 3 As shown, in the multi-cavity aluminum profile mold of this embodiment, the periphery of the end of the mold core 30 protrudes outward to form a raised portion 31, and the raised portion 31 forms a step with the end of the mold core 30, and the two-stage The center of the welding chamber 23 is provided with a discharge chamber 24, the secondary welding chamber 23 surrounds the periphery of the discharge chamber 24, and the outer contour of the secondary welding chamber 23 is located at the upper and lower positions of the discharge chamber 24 and protrudes outward. The main purpose of this structural design is that after the aluminum ingot comes down from the shunt bridge 12, it can first fill the welding cavity 22, and then flow out from the core 30 through the steps. The aluminum raw material first passes through the raised part 31 and then flows out from the discharge cavity 24. , can buffer the pressure on the mold core 30 and reduce the risk of m...

Embodiment 3

[0024] like Figure 2-3 As shown, in a multi-cavity aluminum profile mold of this embodiment, the outer contour of the discharge cavity 24 gradually becomes larger from close to the upper mold 10 to away from the lower mold 20. The main purpose of this structural design is to reduce the pressure of the lower mold 20. Loading capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com