A semi-automatic device for making lead plates

A semi-automated, stereotyped technology, applied in the manufacture of tools, equipment for feeding molten metal into molds, metal processing equipment, etc., can solve the time-consuming and labor-intensive, expensive automated stereotype production equipment, and cannot meet the high efficiency requirements of stereotypes and other issues to achieve the effect of improving efficiency and lowering manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

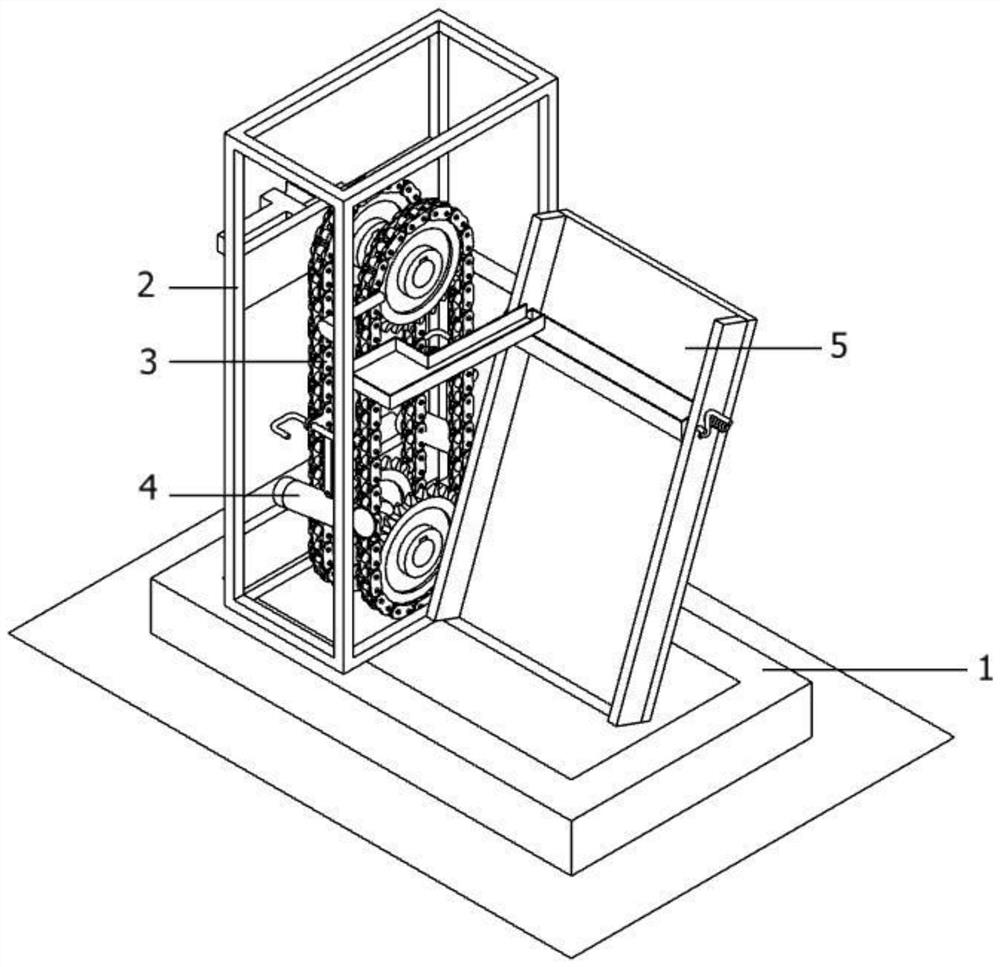

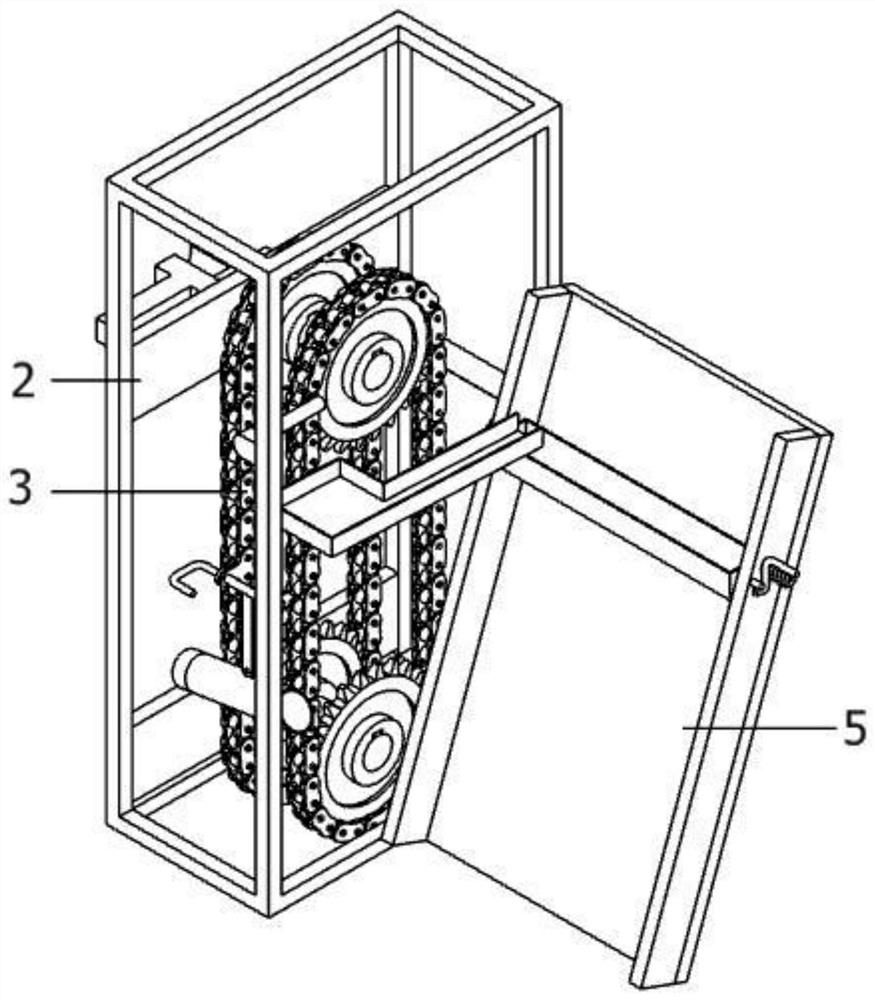

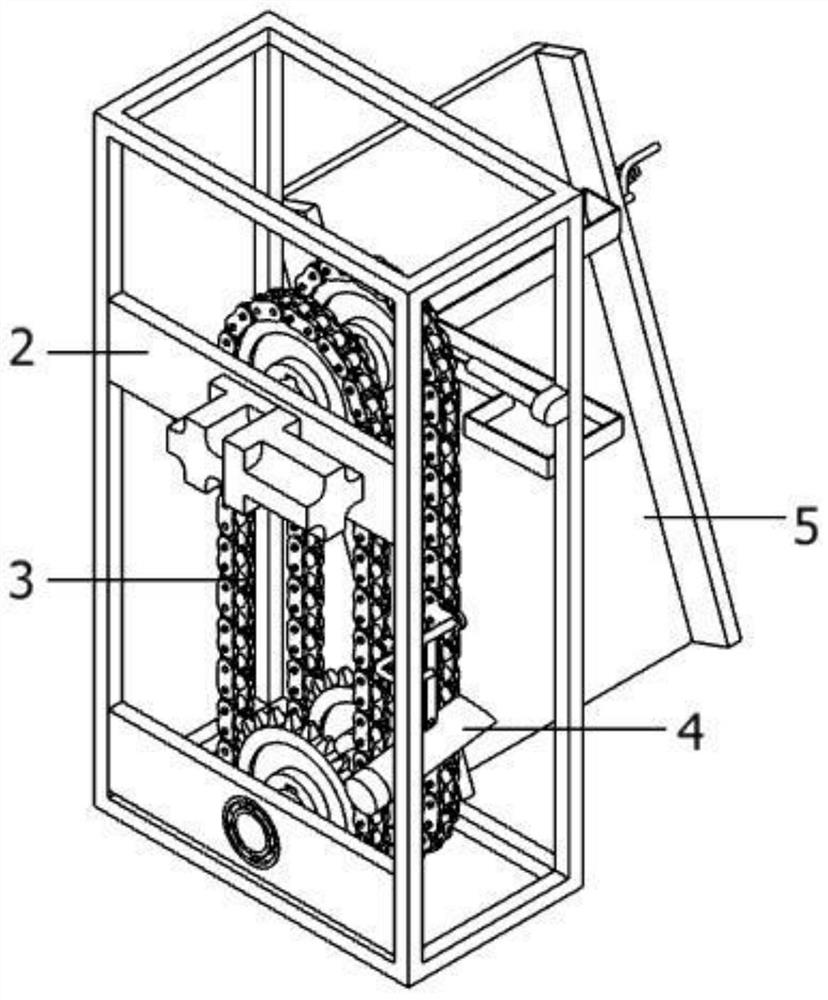

[0034] Append figure 1 Adherent Figure 14 Down:

[0035]The present invention provides a semi-active device for a lead plate, including: rectangular lead water storage container 1, rectangular lead water storage container 1 top surface left side fixed mounting frame 2, rack 2 including Rectangular Frame 201, the upper rectangular plate 202, the lower rectangular plate 203, the bearing A204, the bearing B205, the U-shaped block 206, the angle adjustment lever 207, lead water delivery channel 208, rectangular frame 201 bottom end surface fixedly mounted in rectangular lead water The left side part of the storage container 1, the upper side portion of the rectangular frame 201 is soldered on the left frame plate, and the upper rectangular plate 202 is rotated in the center portion of the upper left end surface of the upper left end surface, and there is a bearing B205, the rectangular frame 201 left The lower rectangular plate 203 is welded under the side frame plate, and the lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com