Method for moving mold of plant fiber molding machine up and down and line rail type up and down mold moving device

A plant fiber and forming machine technology, applied in textiles and papermaking, etc., can solve the problems of unsteady acceleration, inability to control the relative distance between the upper mold and the lower mold, jitter, etc., to achieve flexible sliding up and down, eliminate the risk of uncontrolled sliding, reduce Effect of servo motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

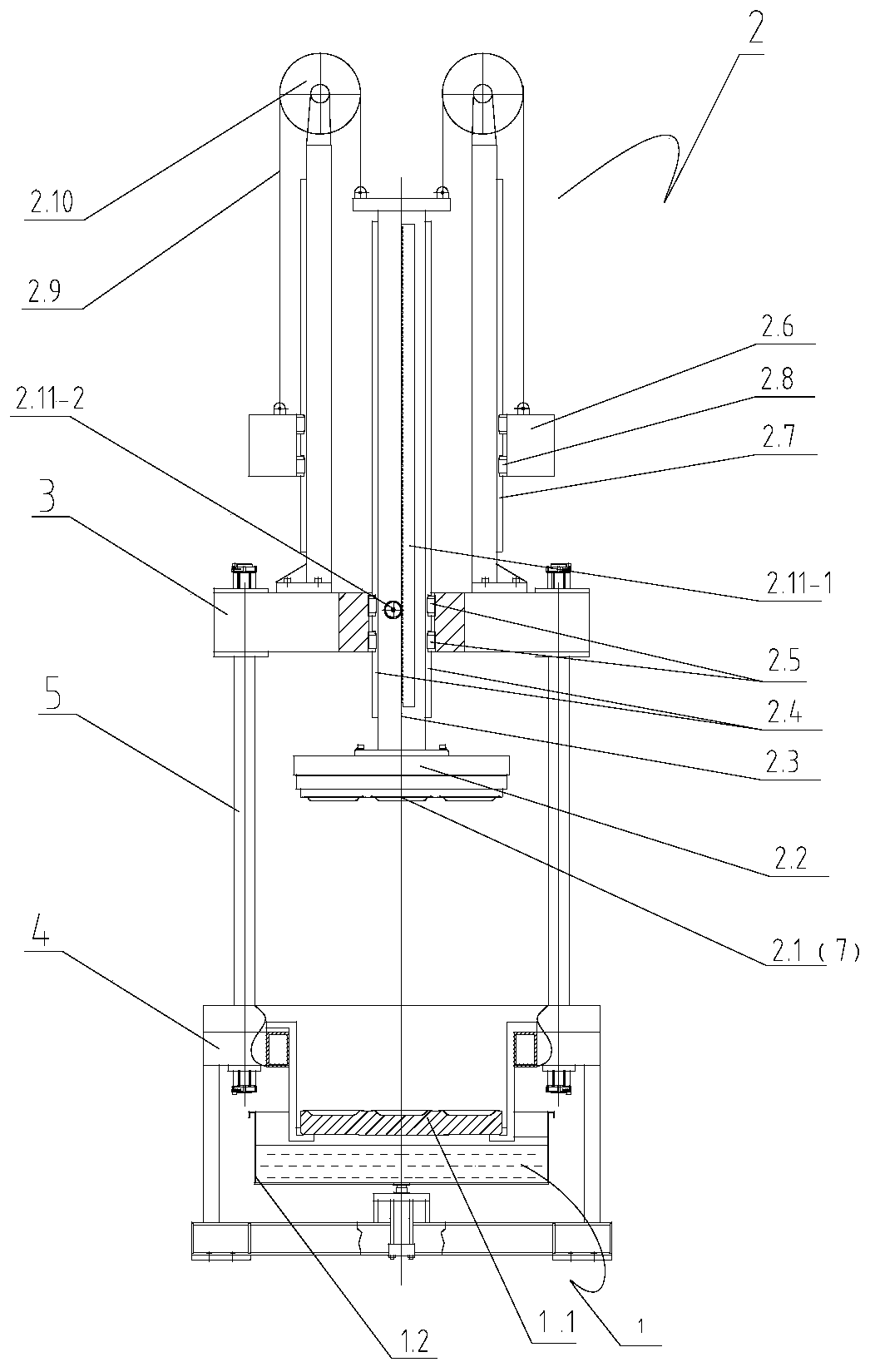

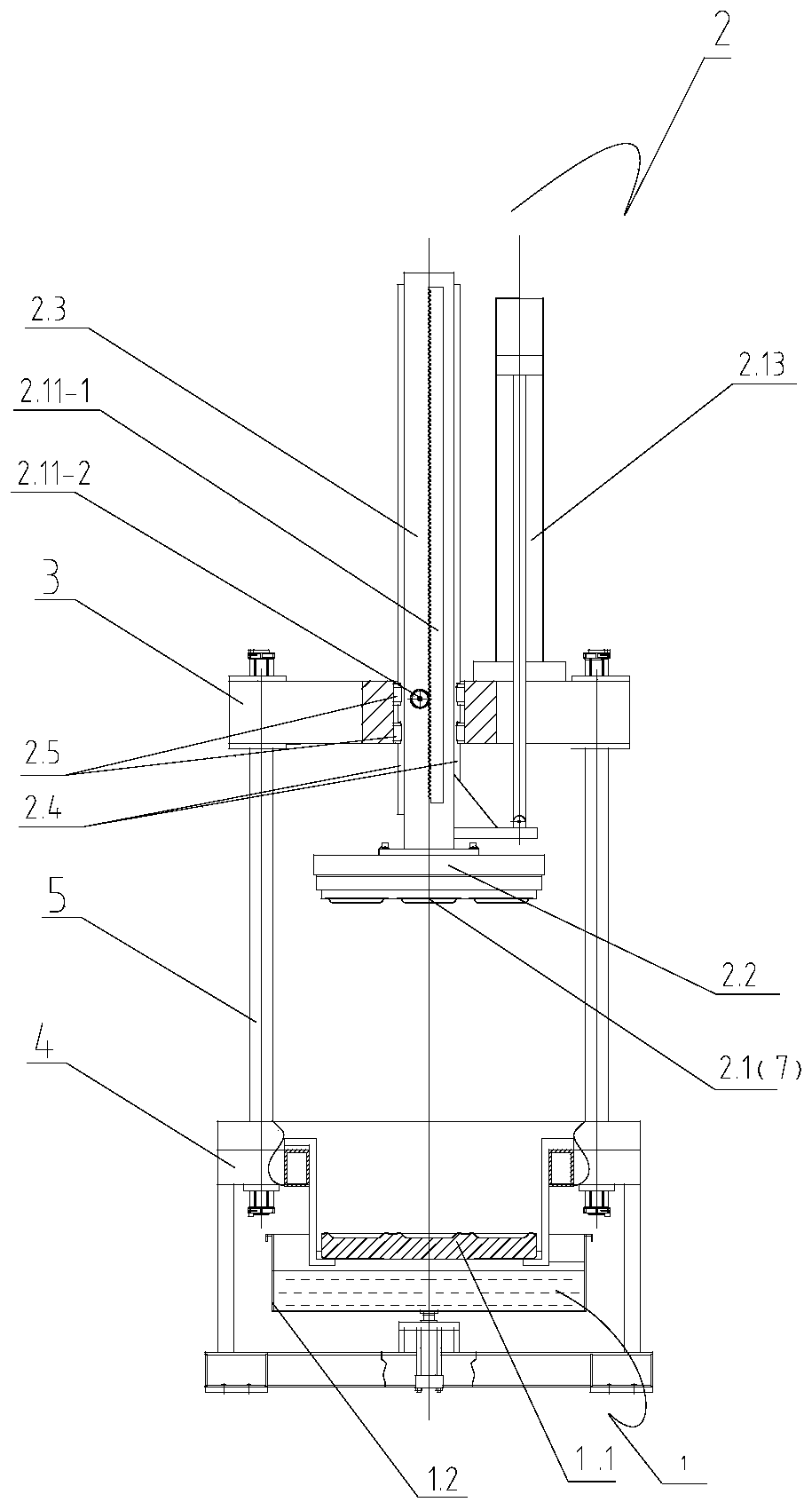

[0053] Example 1, the line rail type up and down mold moving device for the upper mold to move up and down

[0054] Such as figure 1 As shown, the plant fiber molding machine includes a suction filter forming device 1, a wet base transfer mold 7 (a vertical movable mold 2.1 driven by a line rail type up and down mold moving device 2), and a frame.

[0055] Suction filter forming device 1 contains suction filter forming mold 1.1, suction filter forming slurry tank 1.2; frame is composed of pull rod 5, lower frame 4 and upper frame 3, and pull rod 5 separates upper frame 3 and lower frame 4 by a certain distance. fixed together at a distance; the suction filter forming device 1 is arranged in the lower frame 4, and above the suction filter forming device 1, a wet billet transfer mold 7 driven by the line rail type up and down mold moving device 2 is arranged, and the line rail type moves up and down The mold device 2 is installed on the upper frame 3, and in the present embodim...

Embodiment 2

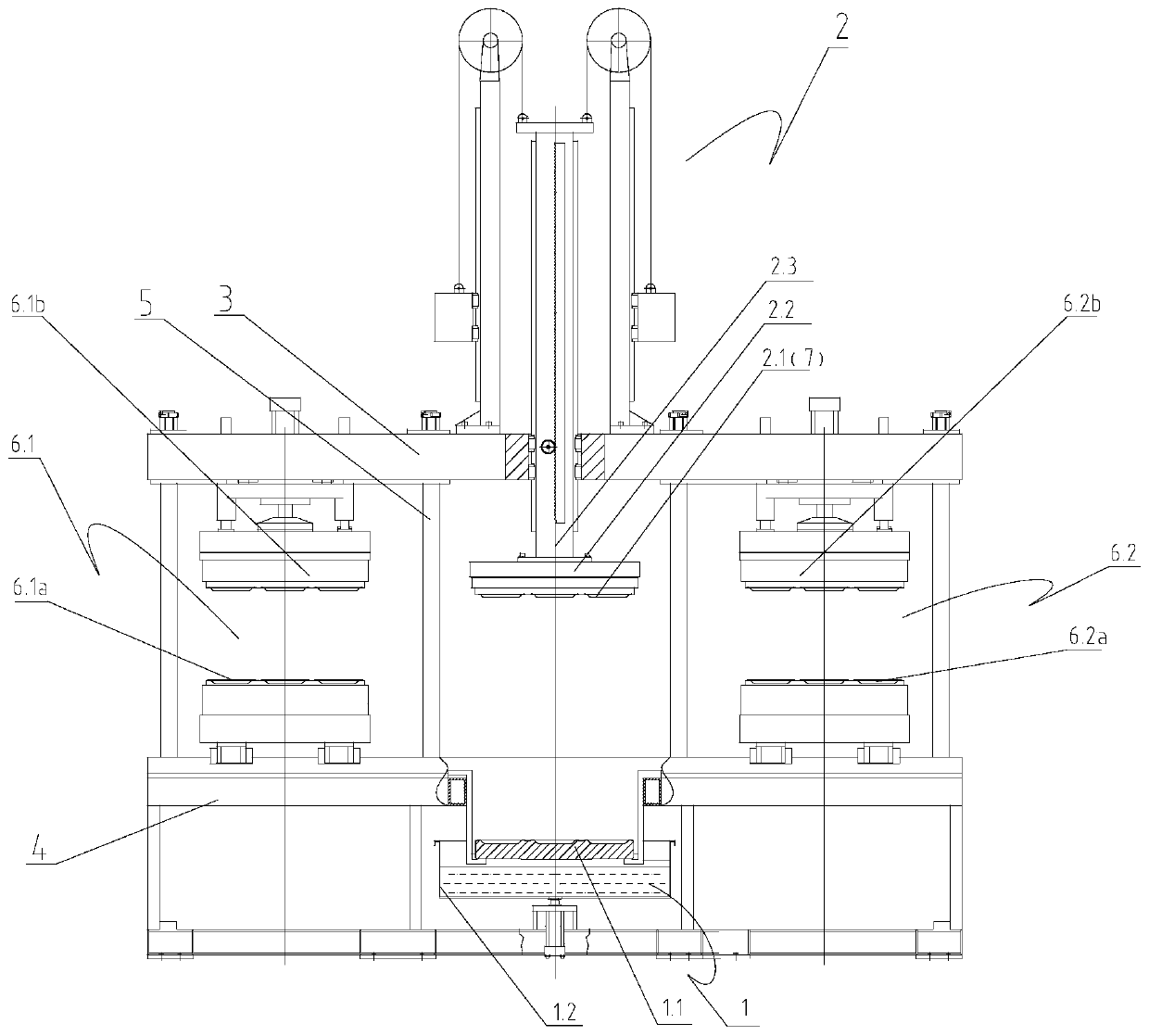

[0078] Embodiment 2, the line rail type up and down mold moving device that the lower mold moves up and down

[0079] Such as Figure 4 As shown, the plant fiber molding machine with the line rail type up and down mold moving device that the lower mold moves up and down includes a suction filter forming device 1, a wet billet transfer mold 7, a left hot pressing device 6.1, and a frame.

[0080]Suction filter forming device 1 contains suction filter forming mold 1.1, suction filter forming slurry tank 1.2; frame is composed of pull rod 5, lower frame 4 and upper frame 3, and pull rod 5 separates upper frame 3 and lower frame 4 by a certain distance. They are fixed together at a distance; the suction filter forming device 1 is set on the lower frame 4, and above the suction filter forming device 1, a wet blank transfer mold 7 is arranged, and the wet blank transfer mold 7 and the left hot pressing upper mold 6.1b can move horizontally Positioned on the lower side of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com