Snow melting device and snow melting vehicle

A snow melting and steam generating device technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of insecurity and low steam utilization efficiency, and achieve the effect of improving utilization rate, observing the surrounding situation clearly, and reducing steam heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but not limited thereto.

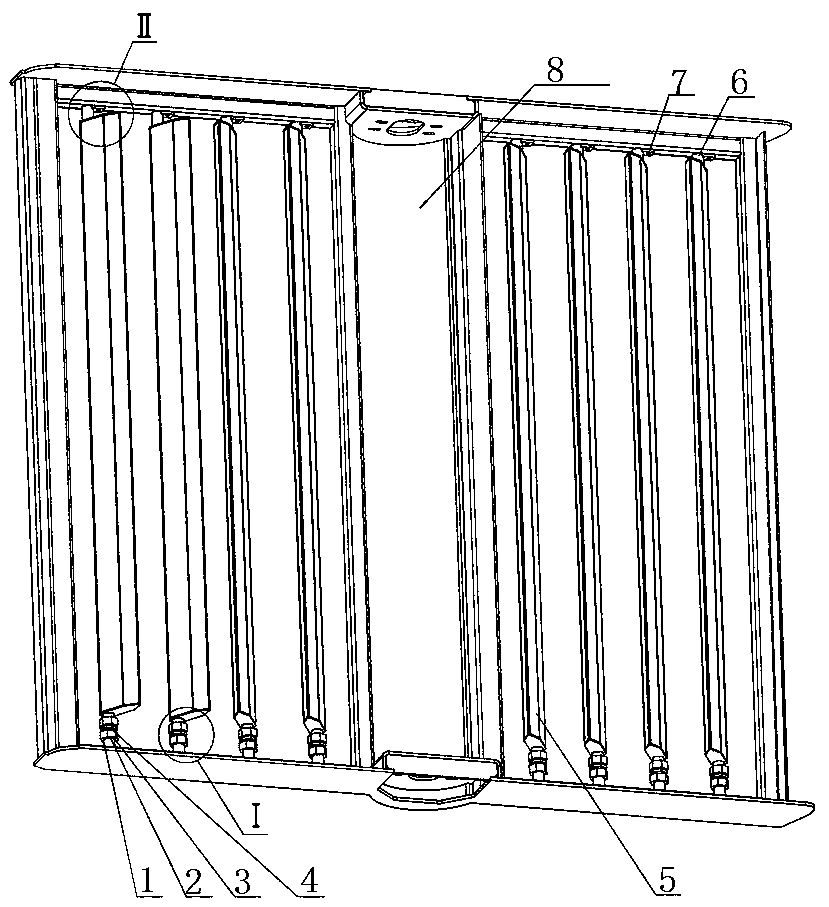

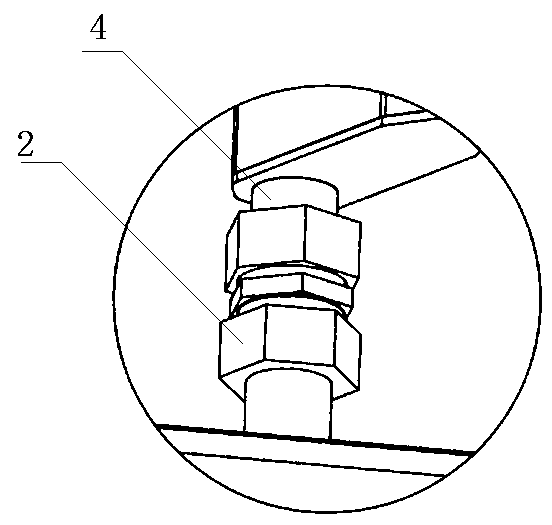

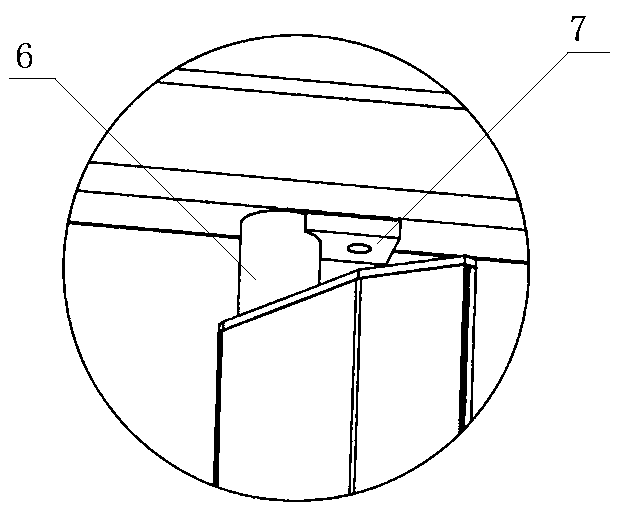

[0027] The specific embodiment 1 of snow melting device, as figure 1 As shown: the snow melting device includes a steam generating device, the steam generating device is connected with a steam cover 8 through a steam pipeline, the steam cover 8 is provided with an opening along the front end of the forward direction during use, and 8 groups of wind turbines are installed in the steam cover 8 in parallel intervals. Knife nozzle 5, such as Figure 4 to Figure 5 As shown, each group of air knife nozzles 5 is formed by bending two square plates and then butt-welded. The air knife nozzles 5 leave a gap of 1mm for air outlet. The high speed when blowing out of the gap in the air can accelerate the fusion of steam and snow, thereby increasing the speed of snow melting. The two ends of air knife spout 5 are also welded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com