Leakage location monitoring system for annular sealing surface of nuclear reactor pressure vessel

A technology for annular sealing and pressure vessel, which is applied in the field of leakage location monitoring system of annular sealing surface of nuclear reactor pressure vessel, can solve the problems of inability to monitor annular sealing surface of nuclear reactor pressure vessel, real-time monitoring of leakage, etc., so as to ensure long-term stable operation and enhance stability , the effect of enhancing reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

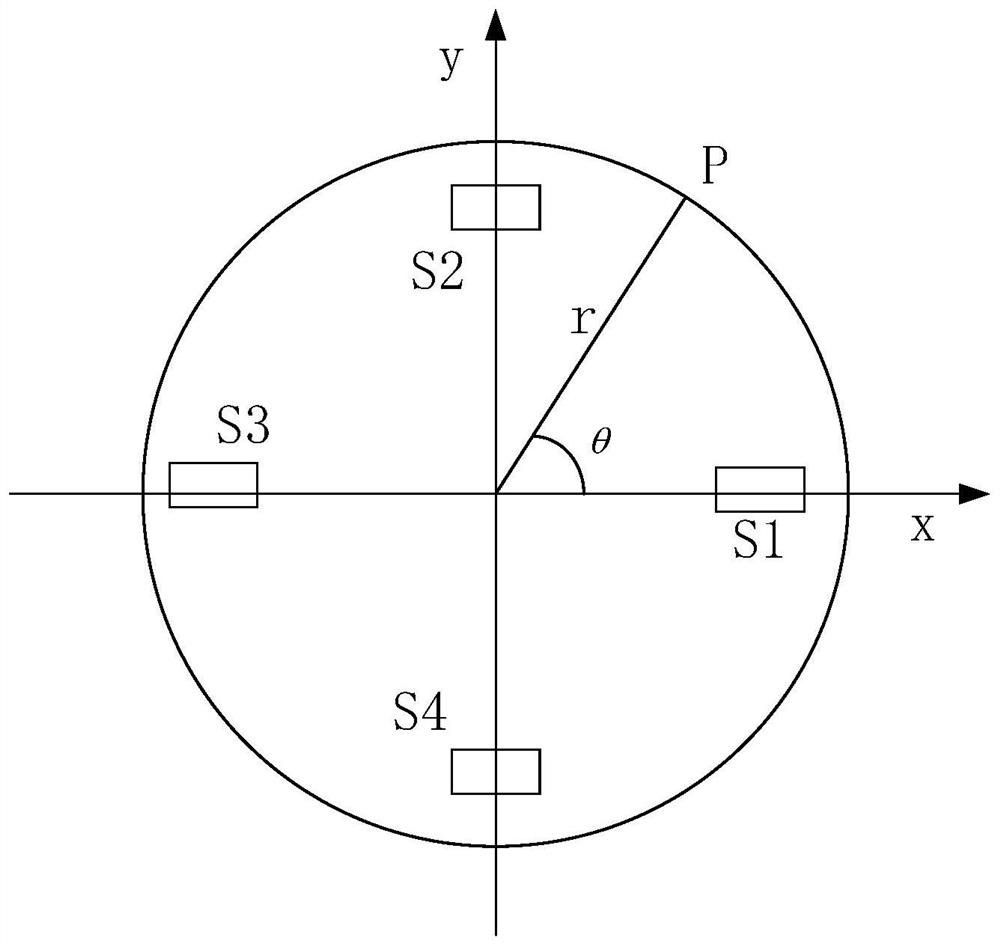

[0067]In the first embodiment, a nuclear reactor pressure vessel annular sealing surface leakage positioning monitoring system is provided, and the annular sealing surface of the present invention is shown.figure 1 The four sensors S1, S2, S3, S4, and four sensors are placed on the annular sealing surface to establish coordinate systems with the origin of the four sensors, and the four sensor coordinates are in turn (X1, 0), (0, y1), (- x10), (0, -y1), Where X1 y1For a known variable that can be set.

[0068]The pipe transmission occurs on the ring of the pressure vessel ring tape, so the source point will only be generated on the circle of R as radius, and once the leak, the leak will be extended on the two-dimensional plane, where R is a known amount that can be measured. . The present invention derives the valid value of the position coordinates (RCOS θ, RSINθ) and its leak source point in accordance with the valid value detection size and leakage attenuation of the four sensors.pAn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com