Novel motor bearing protection structure

A technology of motor bearing and protective structure, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of high cost, large deflection of the beam, and long beam, so as to improve the service life and solve the false The effect of Brinell indentation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

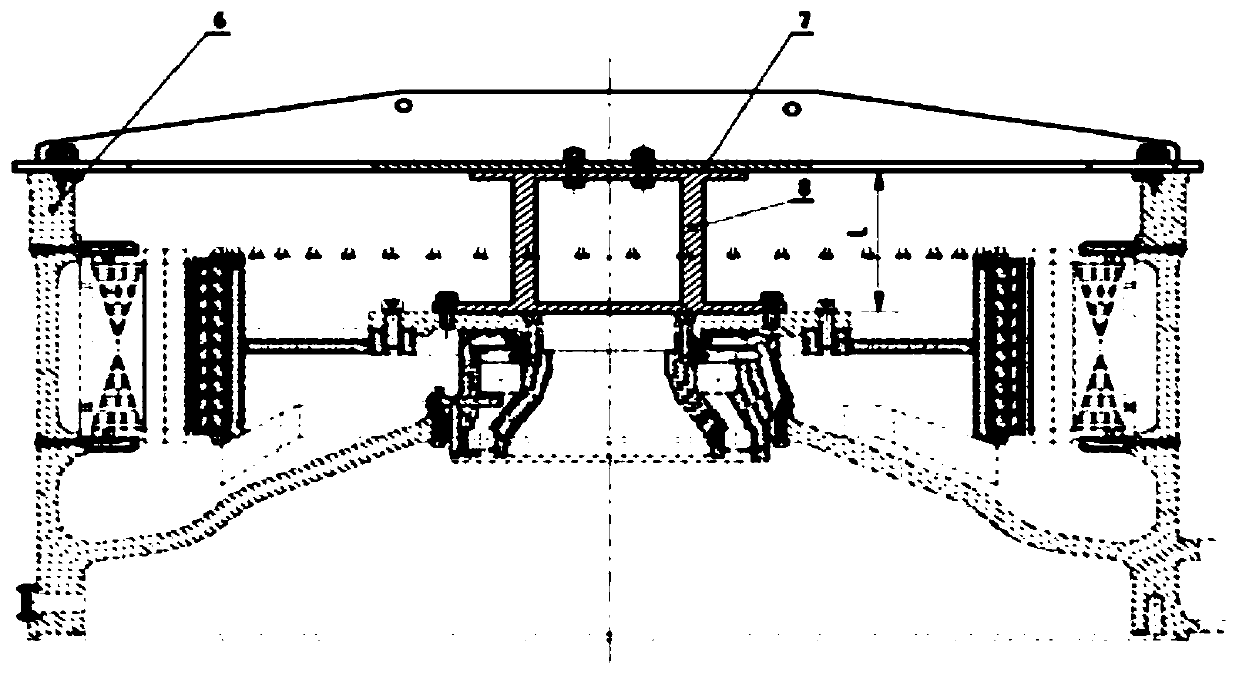

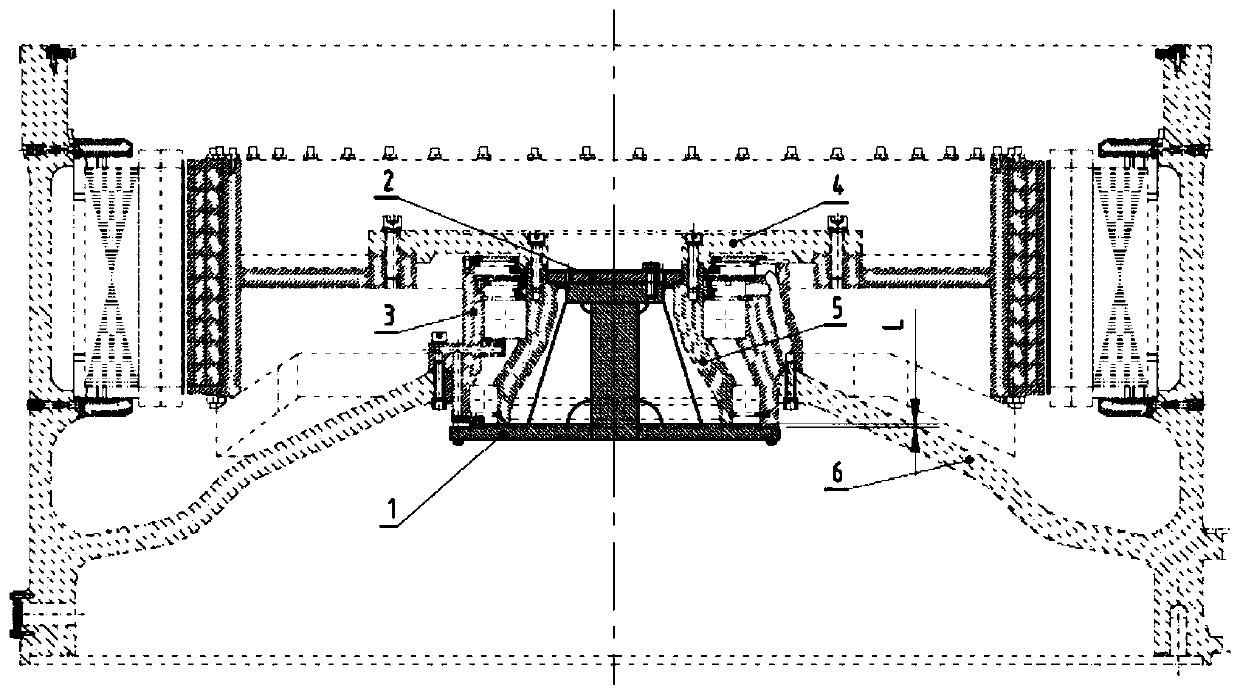

[0033] like figure 2 and image 3 As shown, a new motor bearing protection structure includes a connecting shaft 1 , a fastener 2 and a bearing seat 3 .

[0034] A hollow shaft 5 is arranged inside the bearing seat 3 , flanges 4 for connecting the rotor are arranged symmetrically on both sides of the bearing seat 3 , and the bearing seat 3 has an axisymmetric structure.

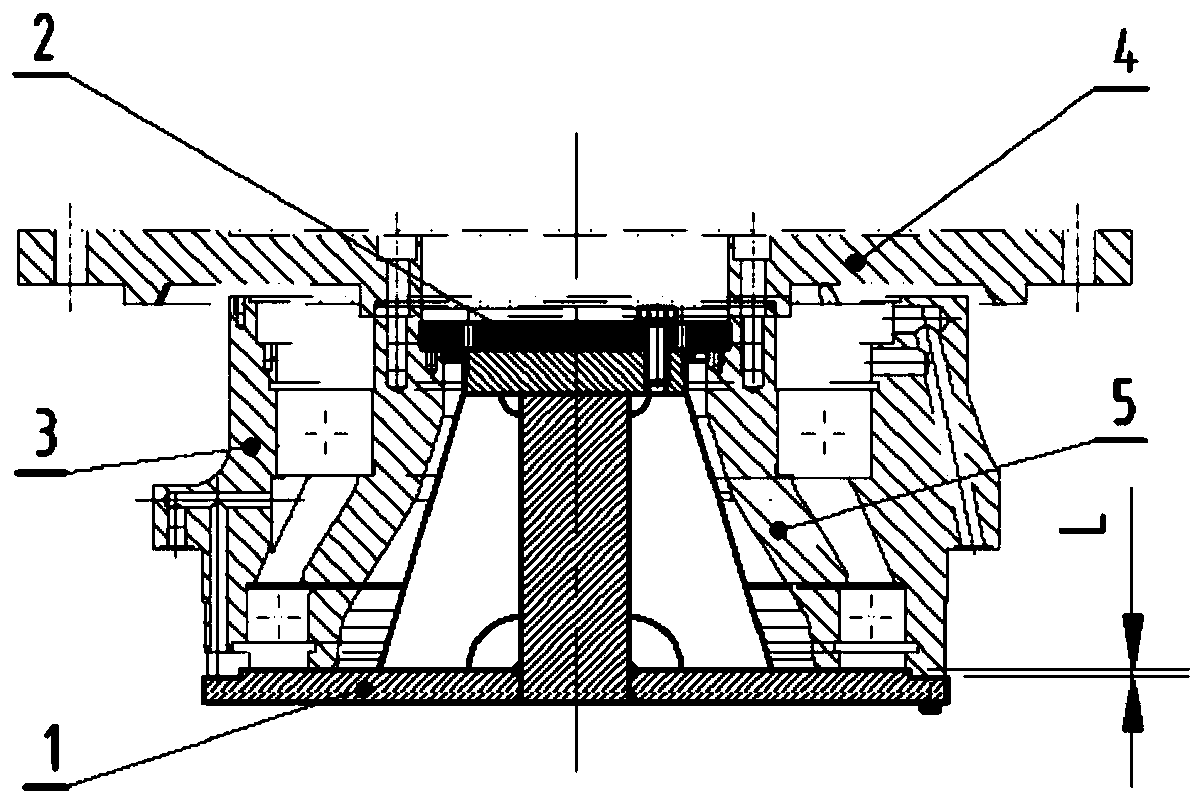

[0035] refer to Figure 4 and Figure 5 , The connecting shaft 1 includes an upper connecting seat 11 , a connecting cylinder 12 and a lower connecting seat 13 .

[0036] The upper connecting seat 11, the connecting cylinder 12 and the lower connecting seat 13 are welded together from top to bottom.

[0037] The lower connection seat 13 is provided with a step 14 matching the bearing seat 3. The step 14 is the axial distance between the hollow shaft 5 and the lower end surface of the bearing sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap