Automatic removal system for package films of tebacco strips

An automatic removal and film technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high work intensity and low degree of automation, and achieve the effect of reducing production equipment, improving the degree of automation, and controlling the error rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

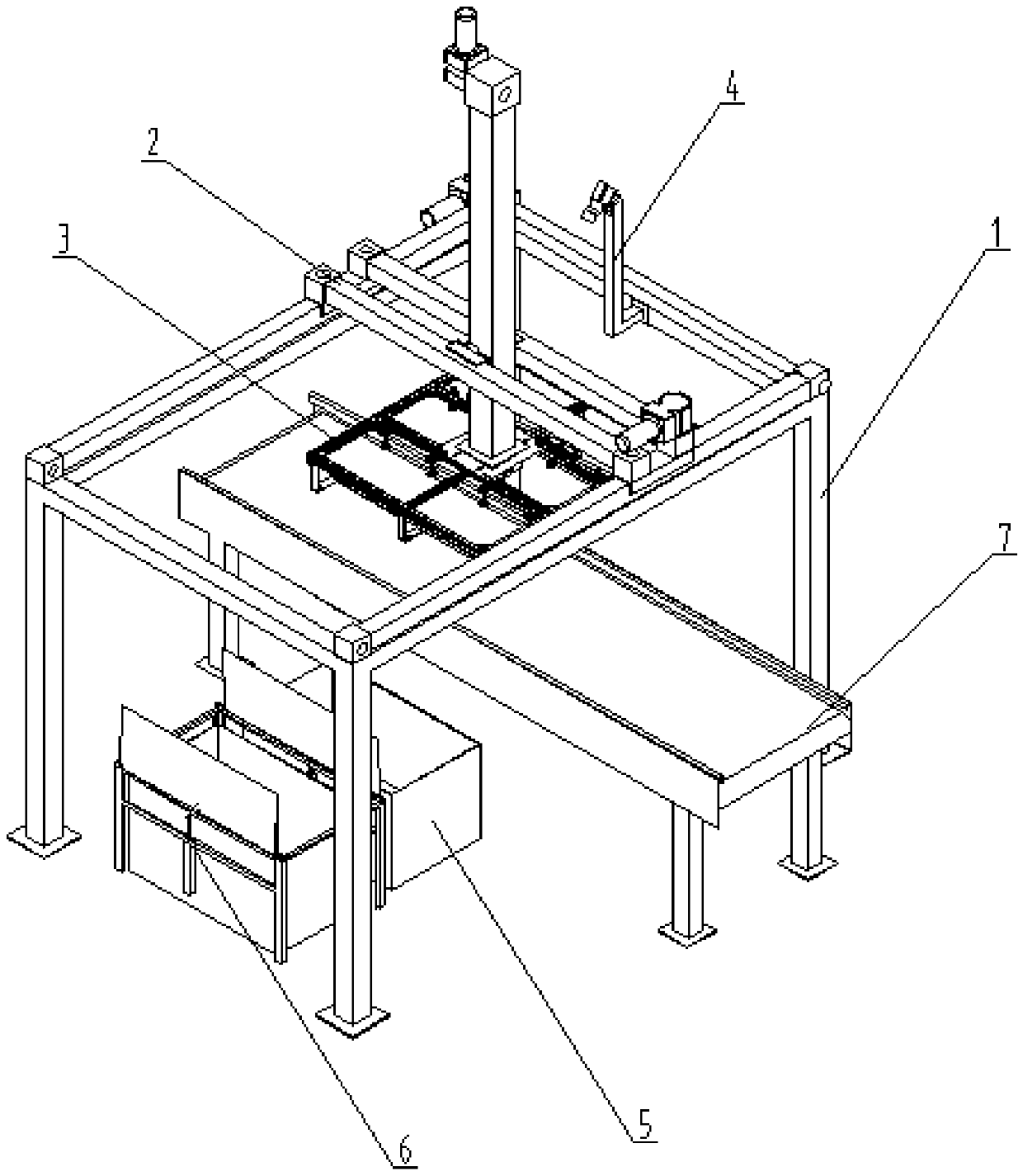

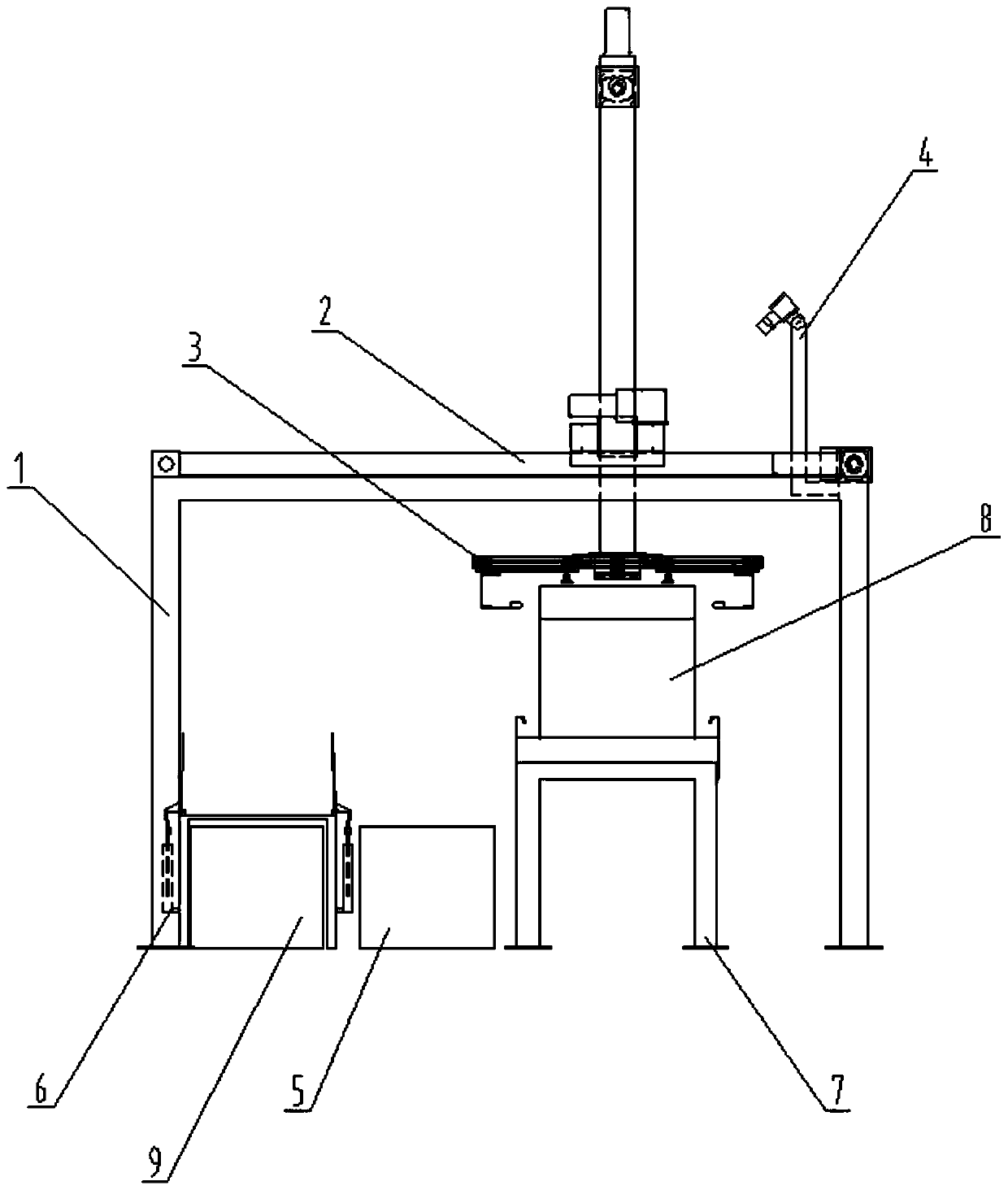

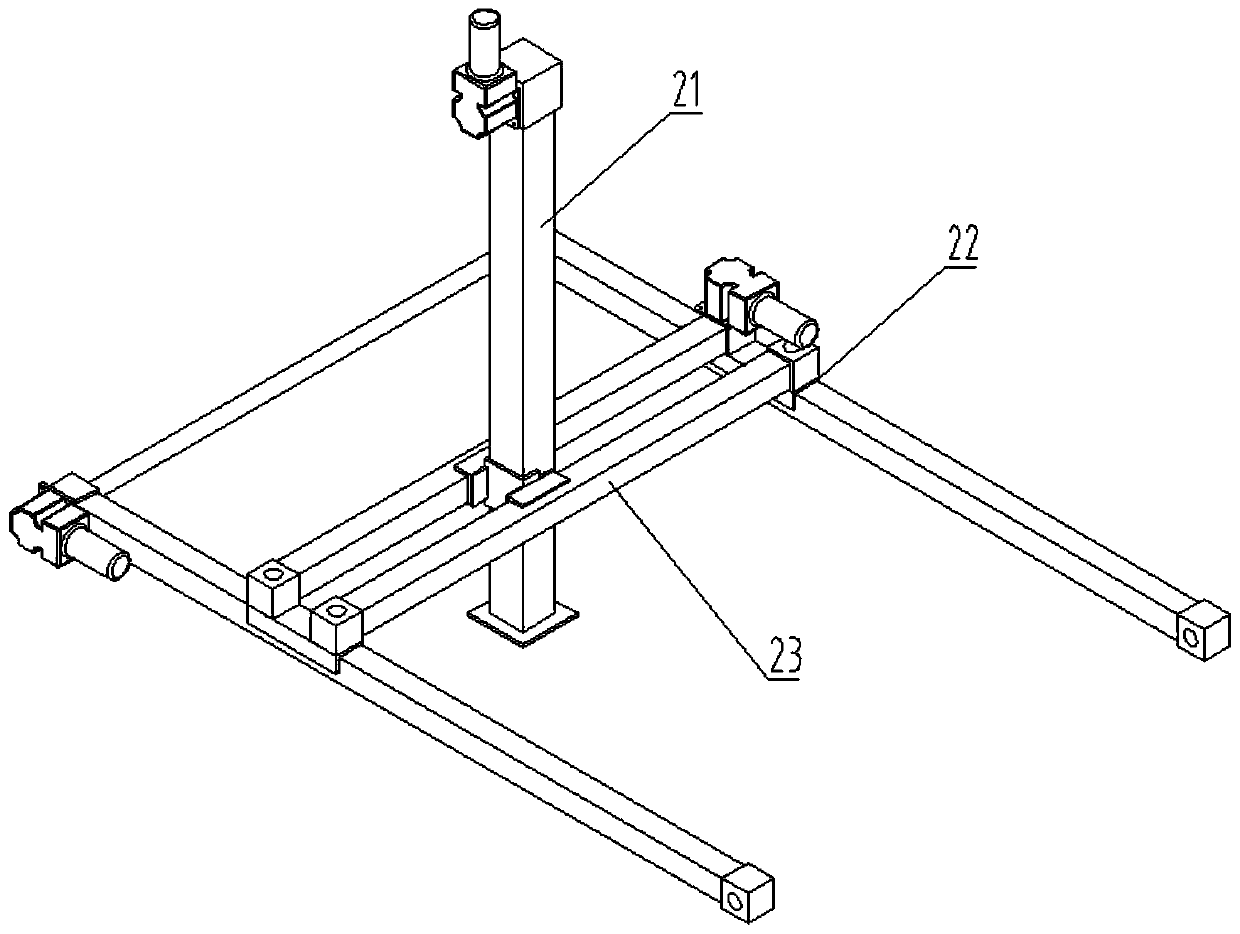

[0022] See figure 1 , figure 2 and see Figure 5 , a kind of film automatic removal system of cigarette package of the present invention comprises: frame 1, right-angle travel mechanism 2, take film jig 3, visual identification device 4, compaction mechanism 6 and belt feeder 7; Said frame 1 It has a square frame and four legs in a horizontal state, and the square frame is used to fix the right-angle walking mechanism 2; the film-taking fixture 3 is fixedly installed under the right-angle walking mechanism 2, specifically, the film-taking fixture 3 and the right-angle walking mechanism 2 are passed through The connecting plate 332 is connected; the right-angle walking mechanism 2 can drive the film-taking fixture 3 to move, and the film-taking fixture 3 can move along the X-axis (horizontal left-right directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com