A high-speed railway track deicing equipment

A technology for high-speed railways and railway tracks, which is applied in the field of rail transportation and can solve the problems of inability to remove ice layers, danger, snow and icing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

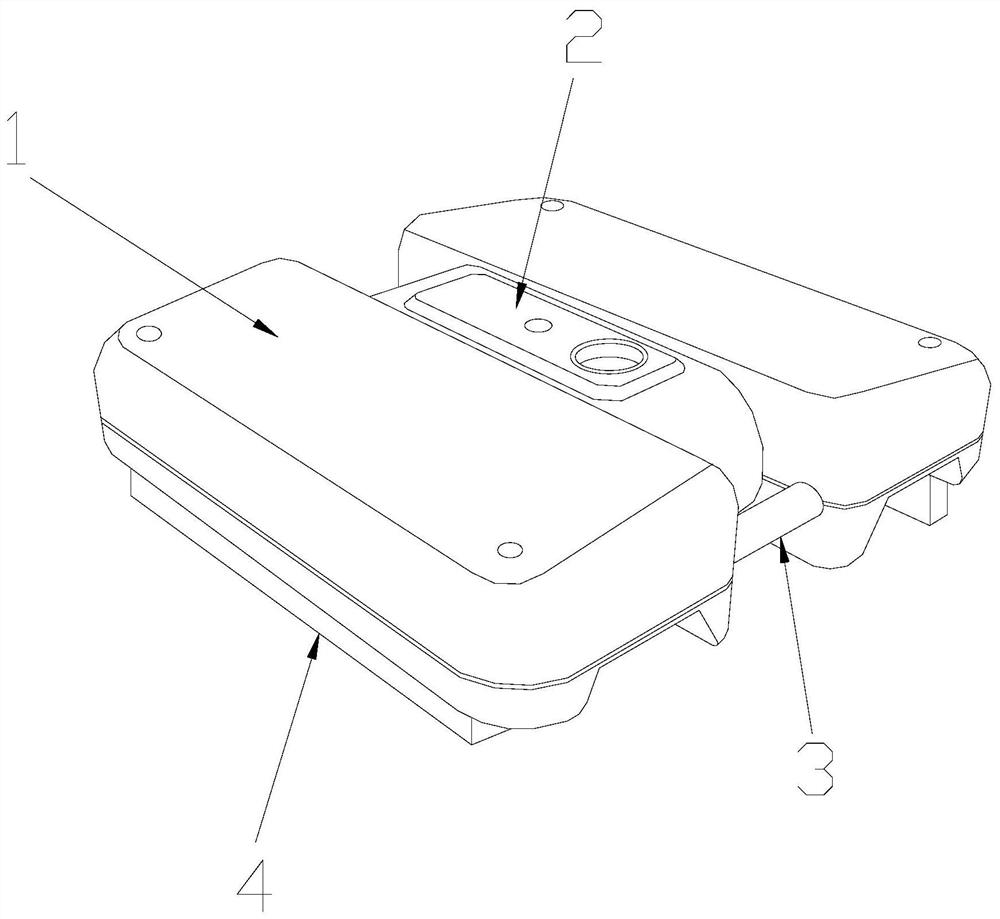

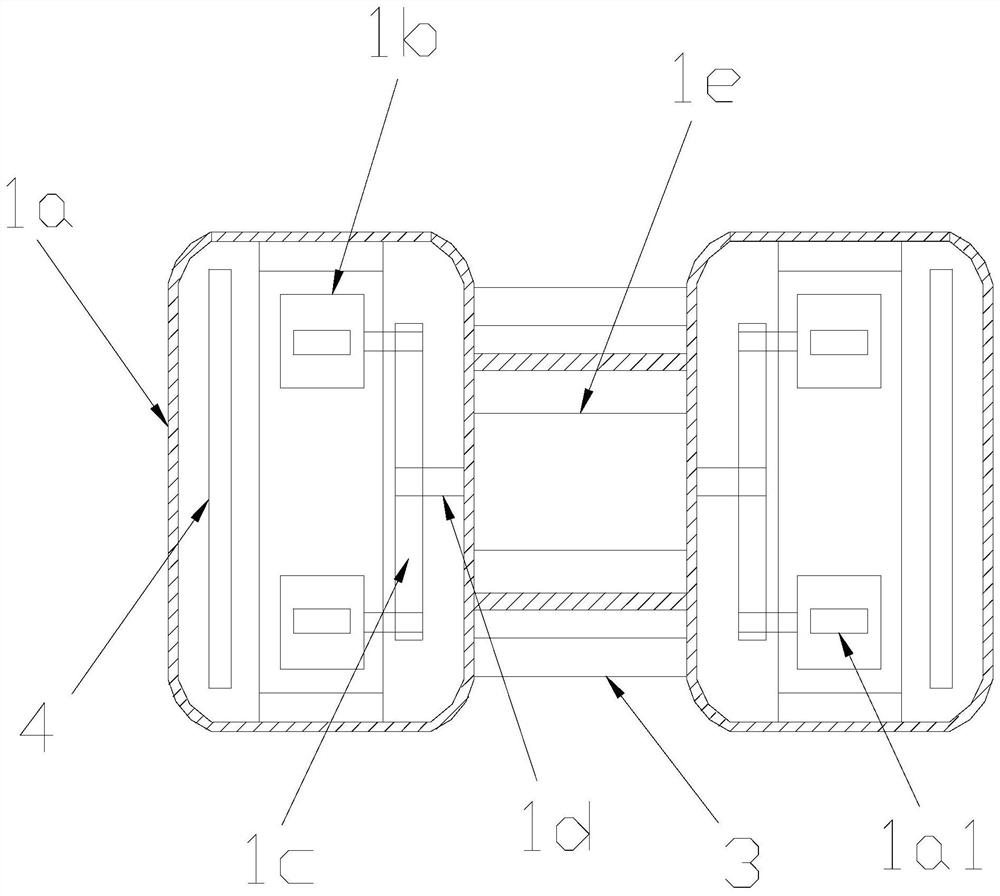

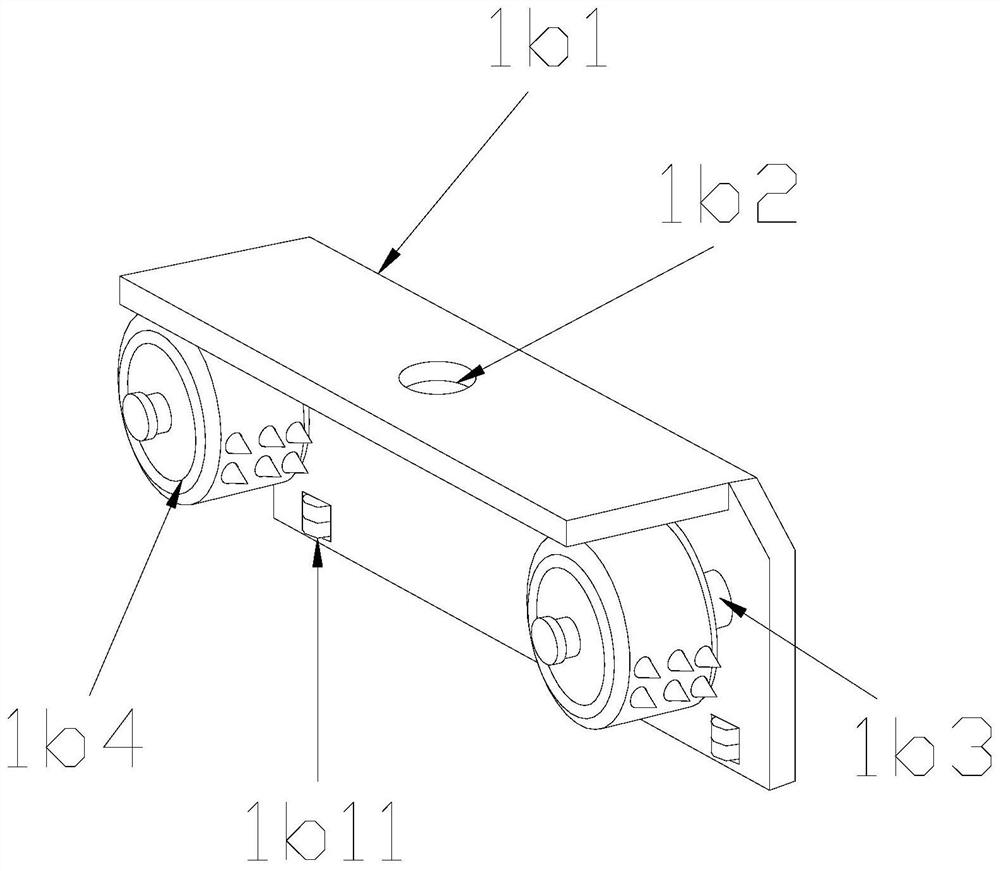

[0030] see Figure 1-Figure 7 , the present invention provides a high-speed railway track deicing equipment, the structure of which includes a sliding deicing machine 1, a signal receiver 2, a telescopic connecting rod 3, and a deicing mechanism 4, and the middle position of the sliding deicing machine 1 is installed with Signal receiver 2, the bottom of the sliding deicer 1 is provided with a deicing mechanism 4, the sliding deicer 1 and the deicing mechanism 4 are movably connected, and the surface of the sliding deicer 1 is provided with There is a telescopic connecting rod 3, and the sliding deicing machine 1 is flexibly connected with the telescopic connecting rod 3. The sliding deicing machine 1 is composed of a body 1a, a rolling and hitting mechanism 1b, a transmission belt 1c, a motor shaft 1d, a double shaft Composed of a motor 1e, the left and right sides of the body 1a are provided with a rolling and hitting mechanism 1b, the body 1a is matched with the rolling and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com