Installation limit structure for transmission oil-sealing cover press plate, and transmission oil-sealing structure

A technology of limit structure and oil sealing cap, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficult long-term stability of assembly quality, affecting production and assembly efficiency, and consuming manpower and material resources. Guarantee assembly quality and consistency, avoid artificial aids correction, and save development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

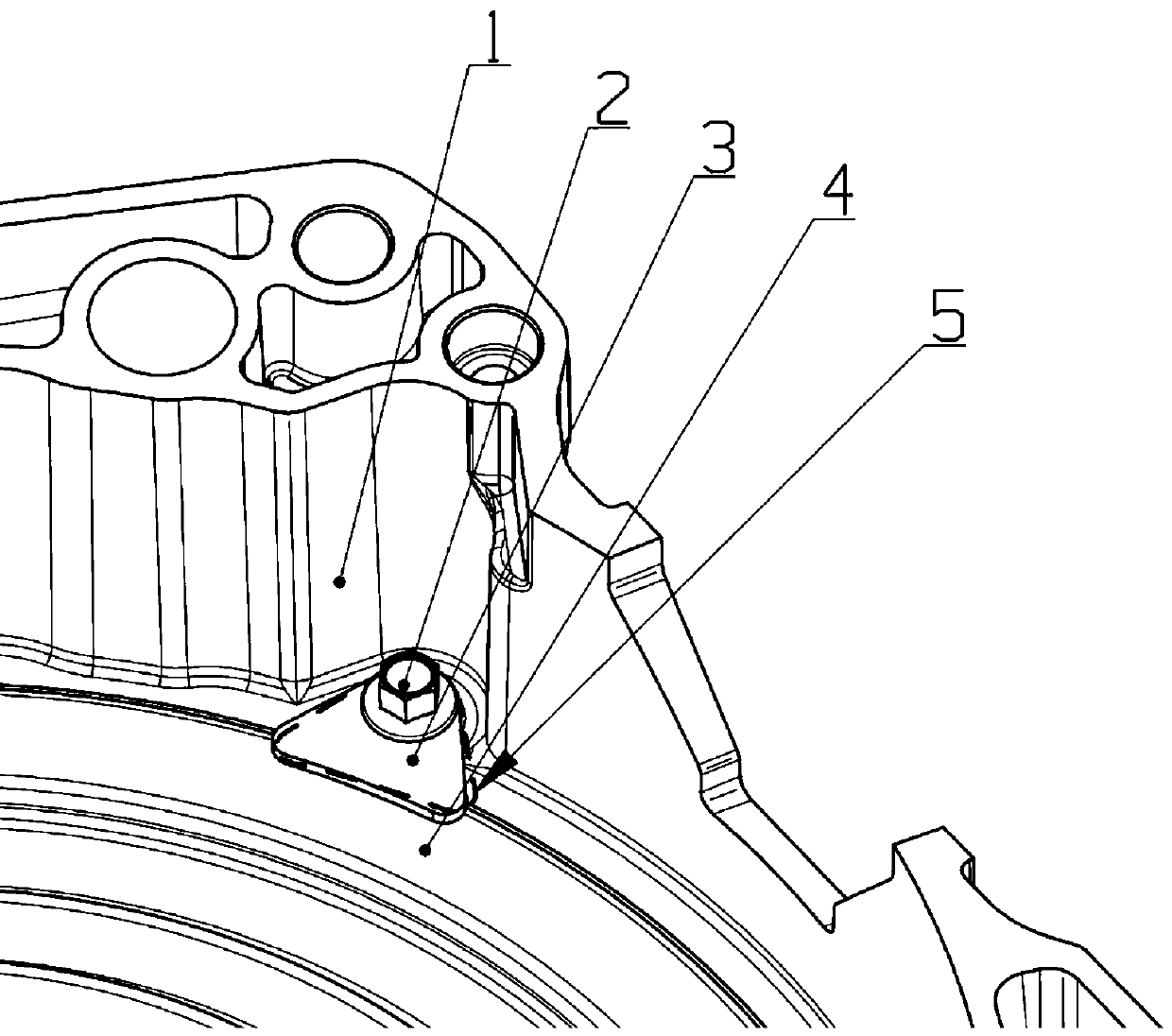

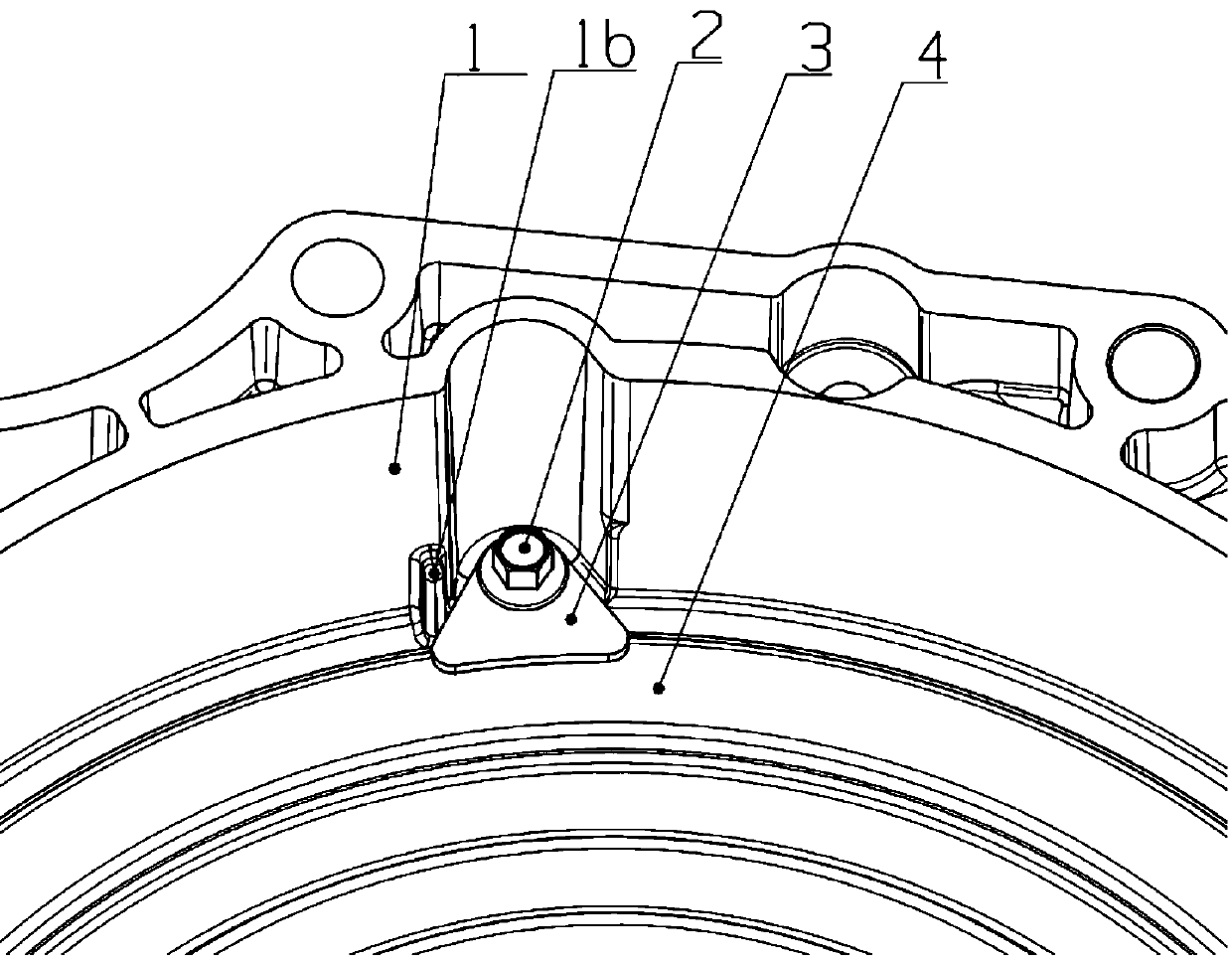

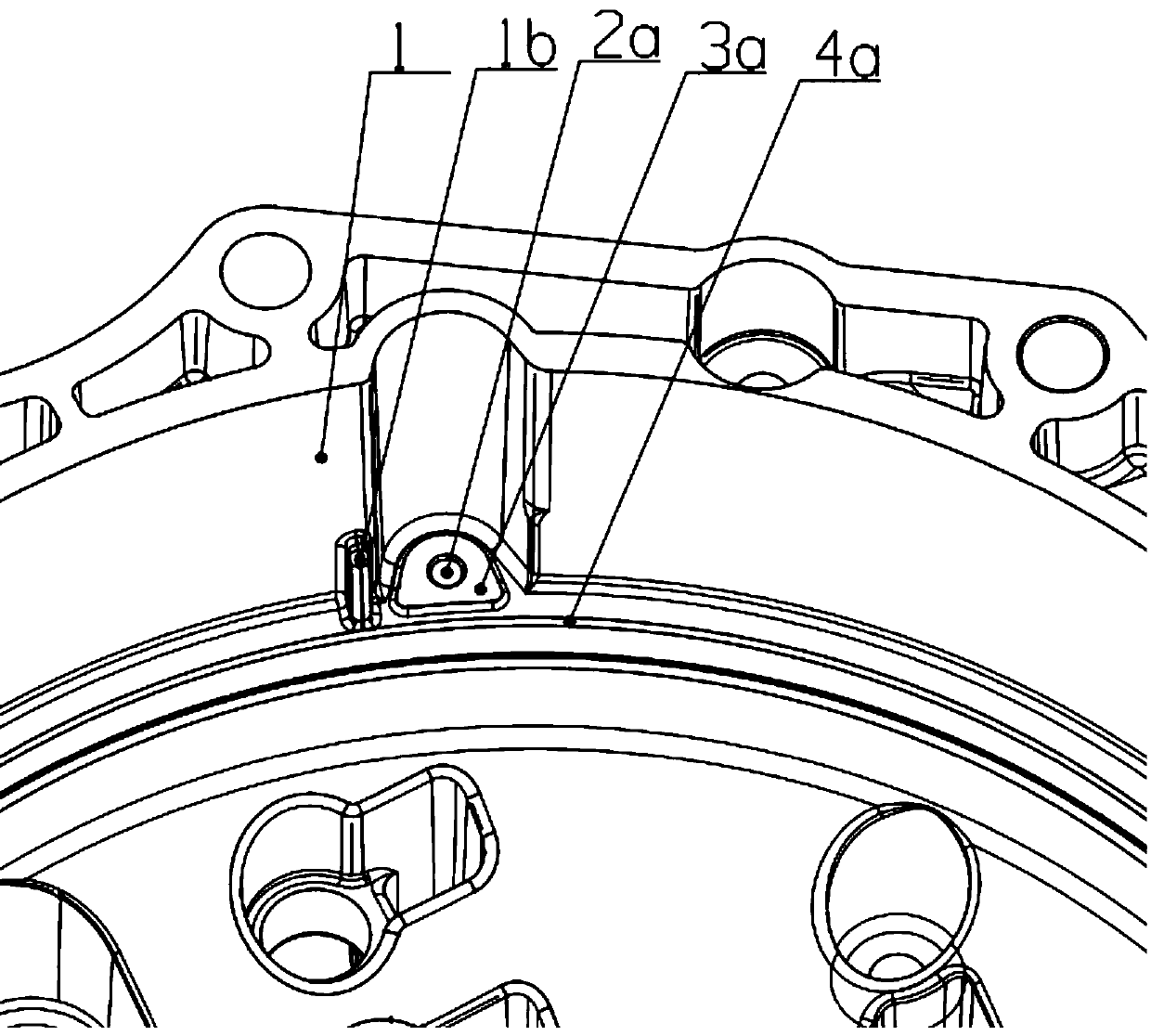

[0020] Such as figure 2 , image 3 As shown, the automobile transmission oil seal cover pressure plate installation limit structure disclosed in the present invention includes a clutch housing 1 and an oil seal cover installation hole 4a provided on the clutch housing 1, and an oil seal cover pressure plate is arranged on the edge of the oil seal cover installation hole 4a The mounting boss surface 3a is provided with threaded holes 2a on the mounting boss surface 3a of the pressure plate of the oil seal cover.

[0021] The intersection of the limiting structural rib plate and the clutch housing 1 is a smooth transition with rounded corners;

[0022] The limiting structural rib 1b has a certain draft angle and is formed integrally with the clutch housing 1 by blank casting.

[0023] The limiting structural ribs 1b are connected to the center of the oil seal cap i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com