Worker operation step specification identification determination and guidance method and system

An operation and worker technology, which is applied in the field of the identification, determination and guidance method and system of the worker's operation step specification, can solve the problems of low efficiency of the instruction book and the inability to perform abnormal reminders, and achieves the effect of preventing operation errors and improving the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

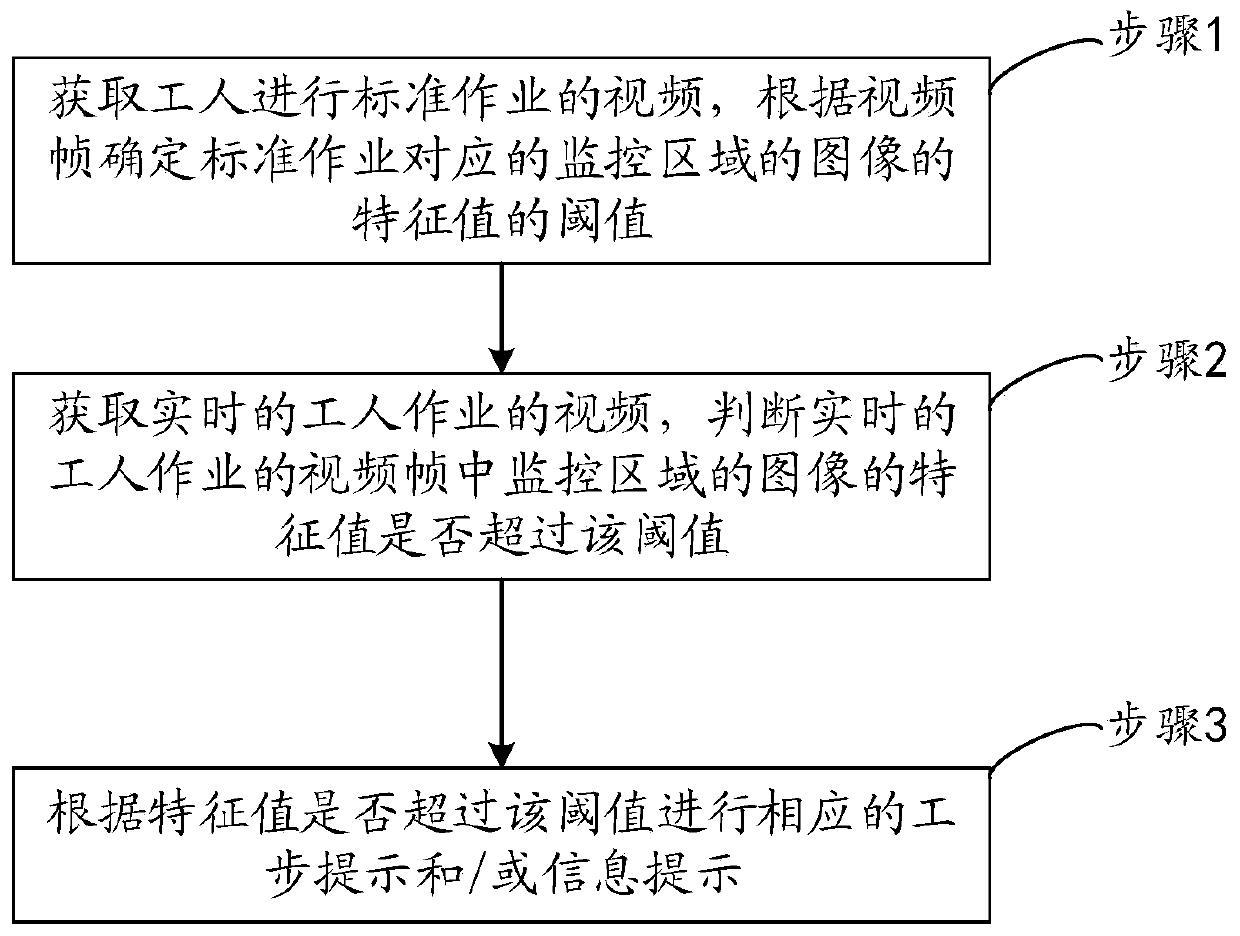

[0050] Embodiment 1 provided by the present invention is an embodiment of a method for identifying, judging and guiding a worker's work step specification provided by the present invention, and this embodiment includes:

[0051]Step 1: Obtain a video of a worker performing a standard operation, and determine the threshold range of the feature value of the image of the monitoring area corresponding to the standard operation according to the video frame.

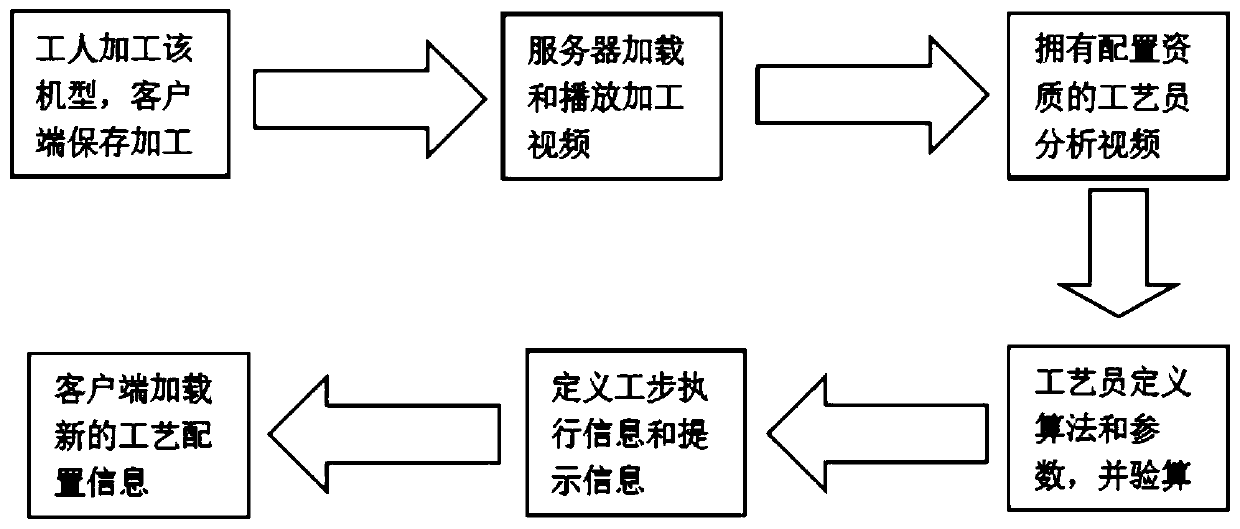

[0052] Specifically, senior operators can complete standardized steps on the production line in accordance with the regulations. The operations include assembly, testing, and spraying. The process engineer selects the operation (assembly, testing, spraying, etc.) area as the monitoring area, and conducts video Play after recording. After defining the difference between standard jobs and invalid jobs, obtain the parameters for calculating the thresholds corresponding to work steps, and determine the thresholds for the feature va...

Embodiment 2

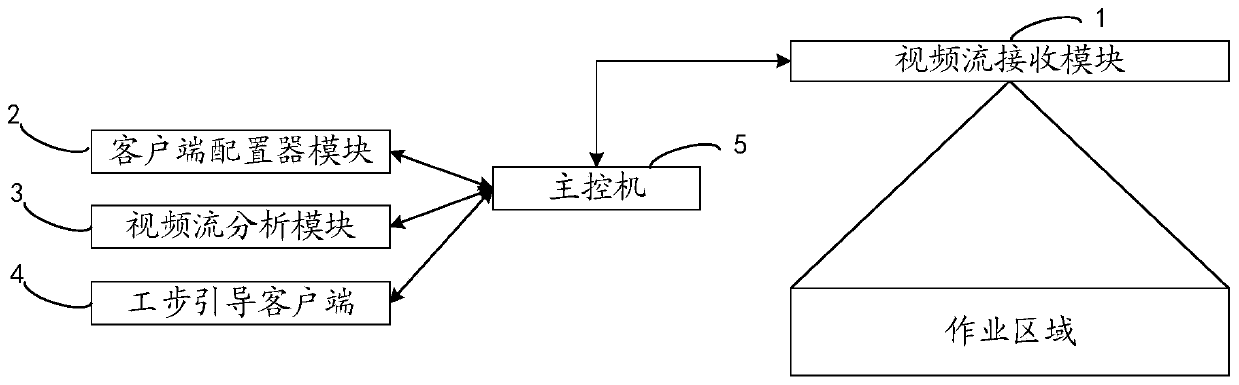

[0076] Embodiment 2 provided by the present invention is an embodiment of a system for identifying, judging and guiding a worker's work step specification provided by the present invention, such as figure 2 Shown is a structural block diagram of an embodiment of a system for identifying, judging, and guiding a worker's work step specification provided by the present invention, consisting of figure 2 It can be seen that an embodiment of a system for identifying, judging and guiding a worker's work step specification provided by the present invention includes a video stream receiving module 1, a client configurator module 2, a video stream analyzing module 3, a work step guiding client 4 and a main control Machine 5. The video stream receiving module 1 , the client configurator module 2 , the video stream analyzing module 3 and the work step guidance client 4 are respectively connected to the main control computer 5 through communication.

[0077] The video stream receiving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com