Miniature size measurer

A measuring device, a technology of micro-size, applied in measuring devices, using optical devices, semiconductor/solid-state device testing/measurement, etc., can solve problems such as inability to measure line widths correctly, and achieve the effect of avoiding operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the invention

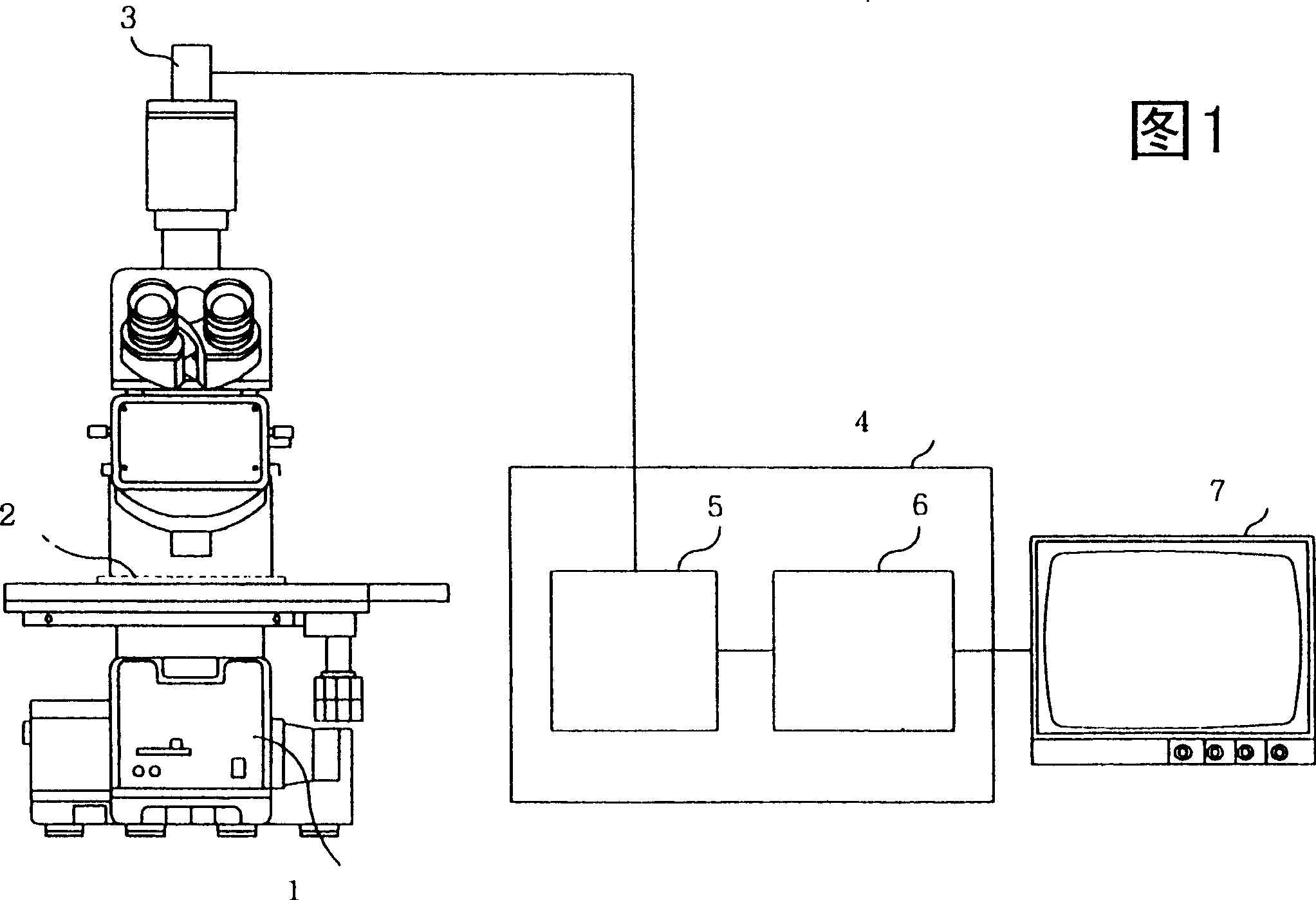

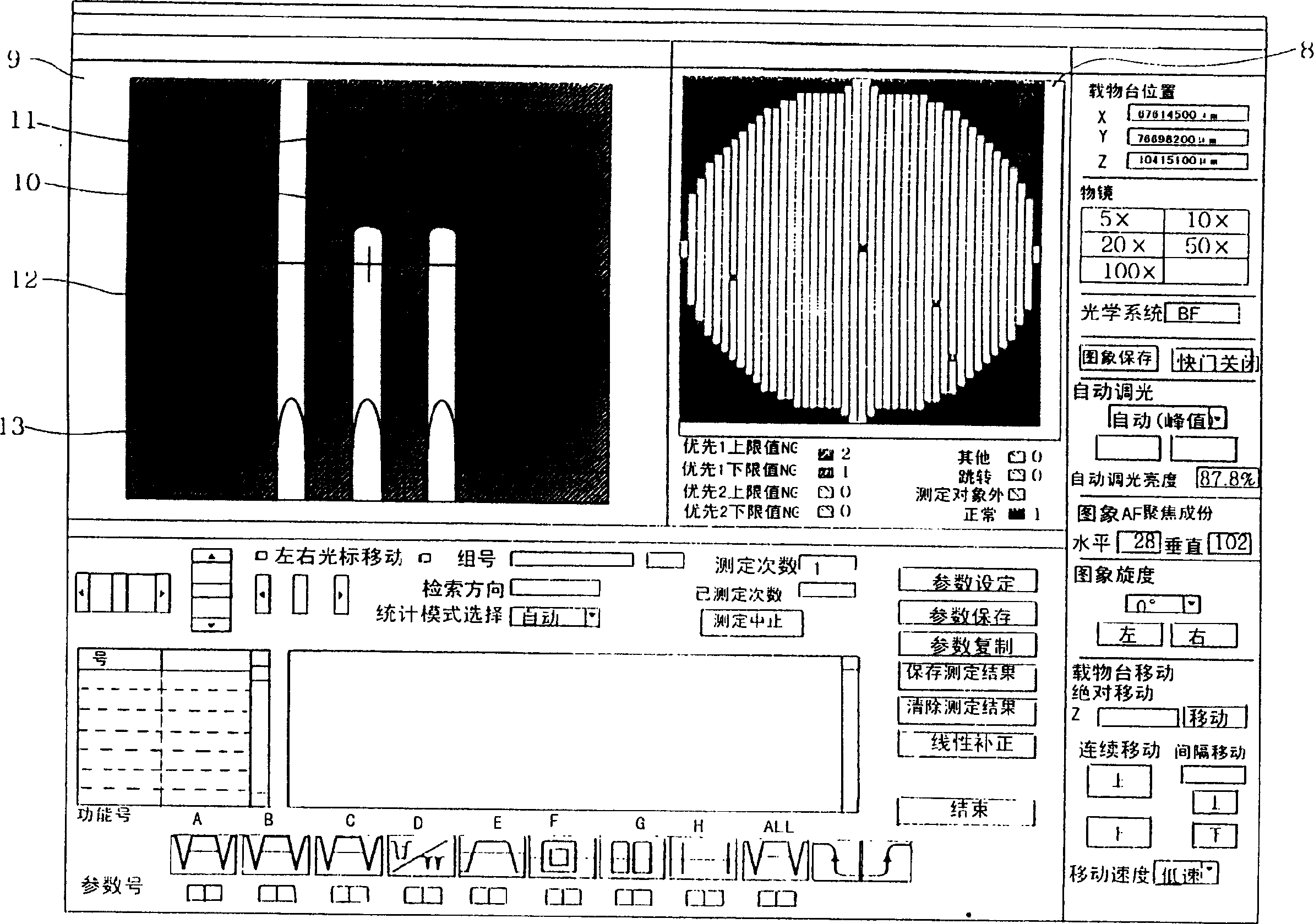

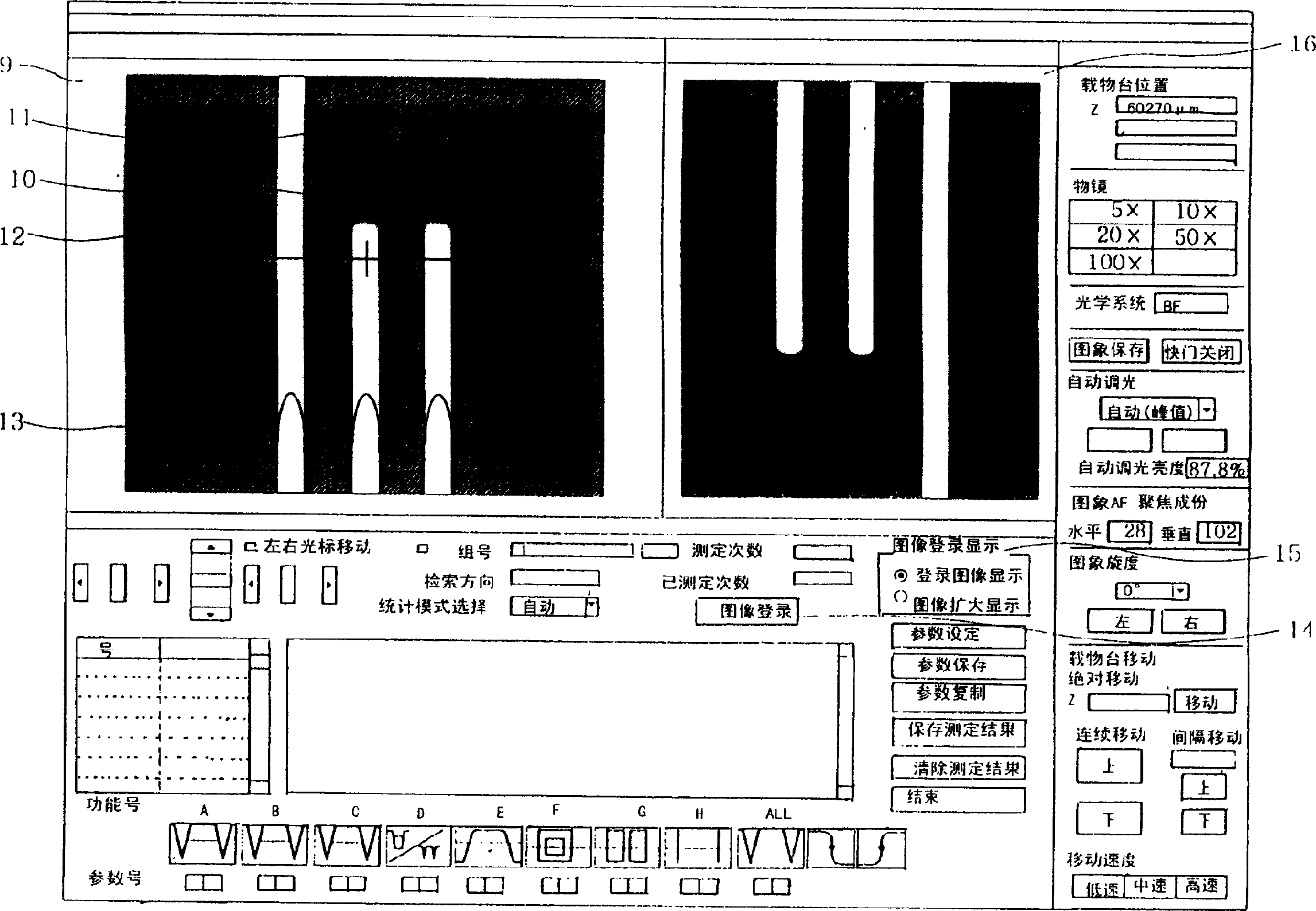

[0018] Embodiments of the present invention will be described in detail below using the drawings. Fig. 1 is a block diagram of a conventional micro-size measuring device. The configuration of the micro-size measuring device shown in this figure can also be used to realize the present invention. Here, in the block (group) structure of the micro-size measuring device shown in this figure, the action different from the action described in the prior art is: the selected one of the many measurement methods pre-recorded on the hard disk 6 The measurement target part of the measurement object corresponding to the method (レシピ) is captured as sample image information according to the combination of the measurement conditions of the measurement method (レシピ), and the corresponding relationship with the measurement method is marked and stored in the hard disk 6, at the same time, when the same object to be measured is measured again based on the reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com