A double-layer winding halbach fault-tolerant motor

A double-layer winding and winding technology, which is applied to the shape/style/structure of windings, winding conductors, electromechanical devices, etc., to avoid overload burnout and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

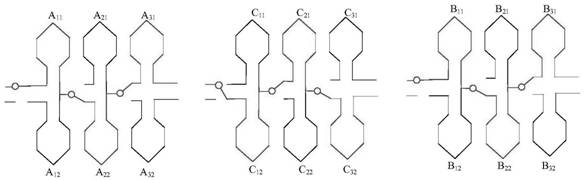

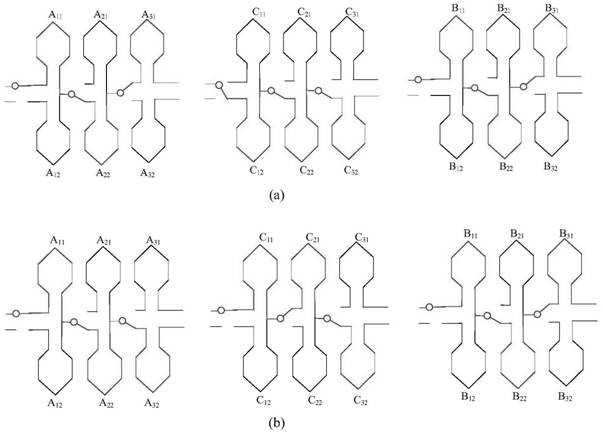

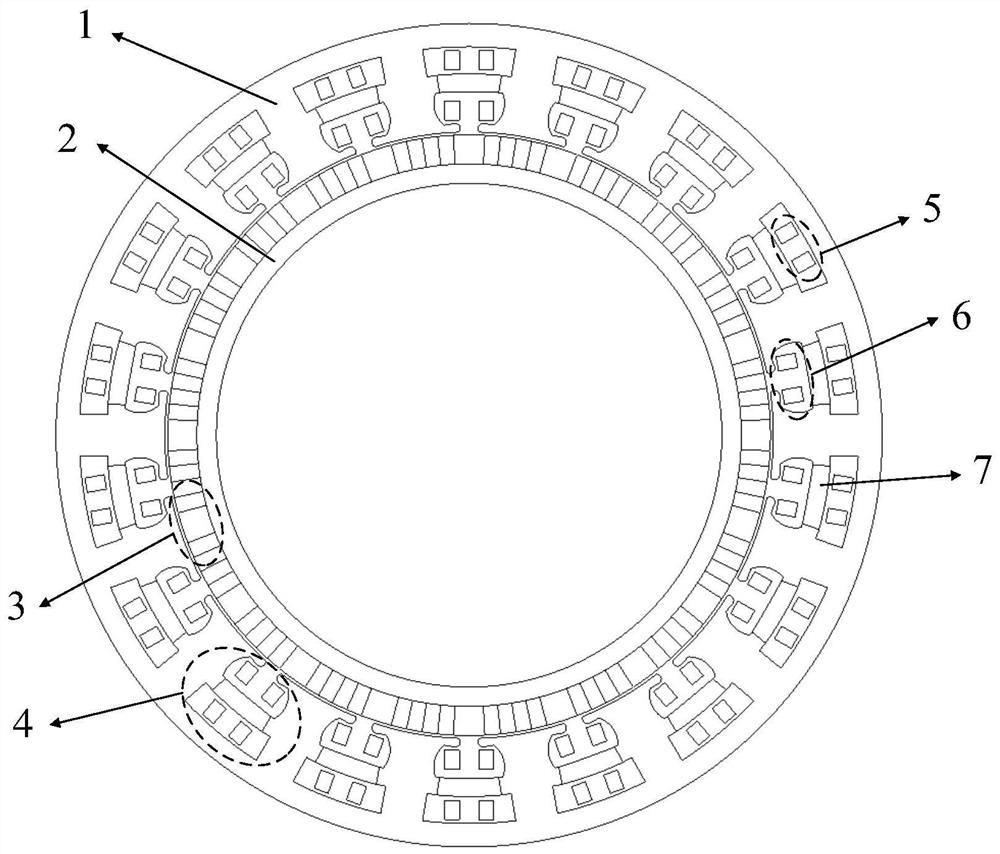

[0021] like figure 1 As shown, a double-layer winding Halbach fault-tolerant motor includes a stator 1 and a rotor 2. The surface of the rotor 2 is covered with permanent magnets 3 composed of Halbach arrays. The stator 1 includes a number of stator slots 4 evenly distributed along the circumference. like figure 2 As shown, the stator slot 4 is radially divided into an upper layer slot and a lower layer slot by a slot wedge 7 . like image 3 As shown, the upper groove has a fan-shaped structure along the radial cross-section, where the arc length at the top and the arc length at the bottom of the fan-shaped structure I 1 , I 2 Expressed by formulas (1) and (2); this structure facilitates the winding of the winding. like Figure 4 As shown, the lower groove has a circular arc wine glass structure along the radial section, and the arc length of its side is I 3 Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com