Hard hat sterilizer

A technology for safety helmets and sterilizers, applied to chemical instruments and methods, cleaning methods and utensils, irradiation, etc., can solve the problems of slow cleaning methods, low cleaning efficiency, and large volume of cleaning devices, and achieve convenient use and simple operation , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

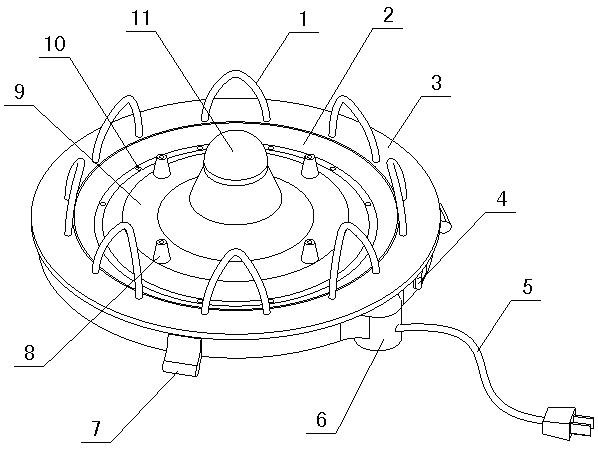

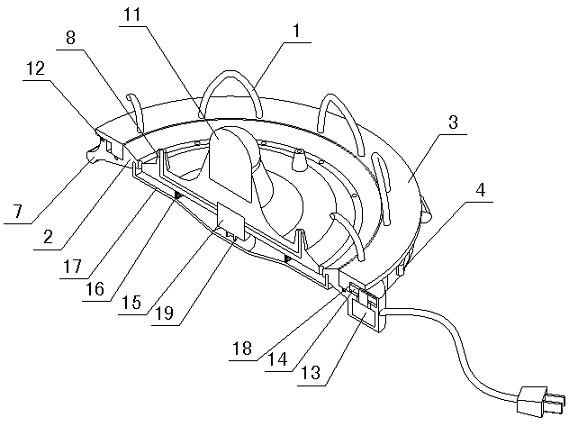

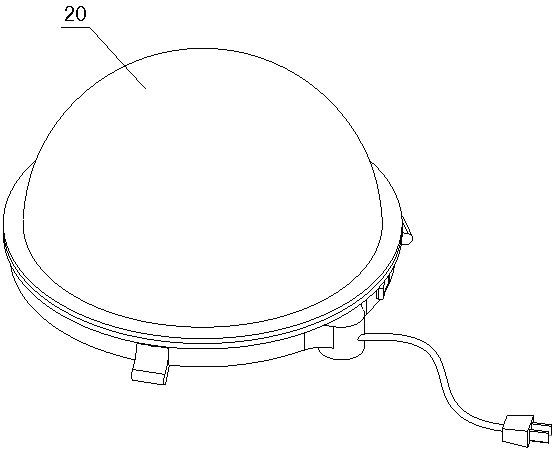

[0015] The safety helmet sterilizer of the present invention is realized in this way. It is composed of a main body rotating device and a disinfection cleaning device. The main body rotating device is composed of a fixed arc rod (1), a fixed frame (2), a turntable (3), a switch (4), and a power cord (5), motor casing (6), support feet (7), balls (12), motor (13), drive gear (14) and ring gear (18), and the turntable (3) is rotatably placed on the fixed frame (2), the bottom of the fixed frame (2) is fixed with at least three legs (7), the fixed frame (2) is a circular frame, and the fixed frame (2) has a groove, A plurality of rotatable balls (12) are placed on the top of the fixed frame (2), and are in contact with the bottom of the turntable (3), and a plurality of rotatable balls (12) are placed at the bottom of the groove. The inner side of the frame (2) is a slope, the outer diameter of the turntable (3) is larger than the outer diameter of the fixed frame (2), the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com