An intelligent extrusion machine

An extruder, intelligent technology, applied in the direction of press, metal extrusion, material forming press, etc., can solve the problems of low extrusion efficiency, high consumption, affecting production efficiency, etc., to achieve efficiency improvement, speed improvement, The effect of bubble removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

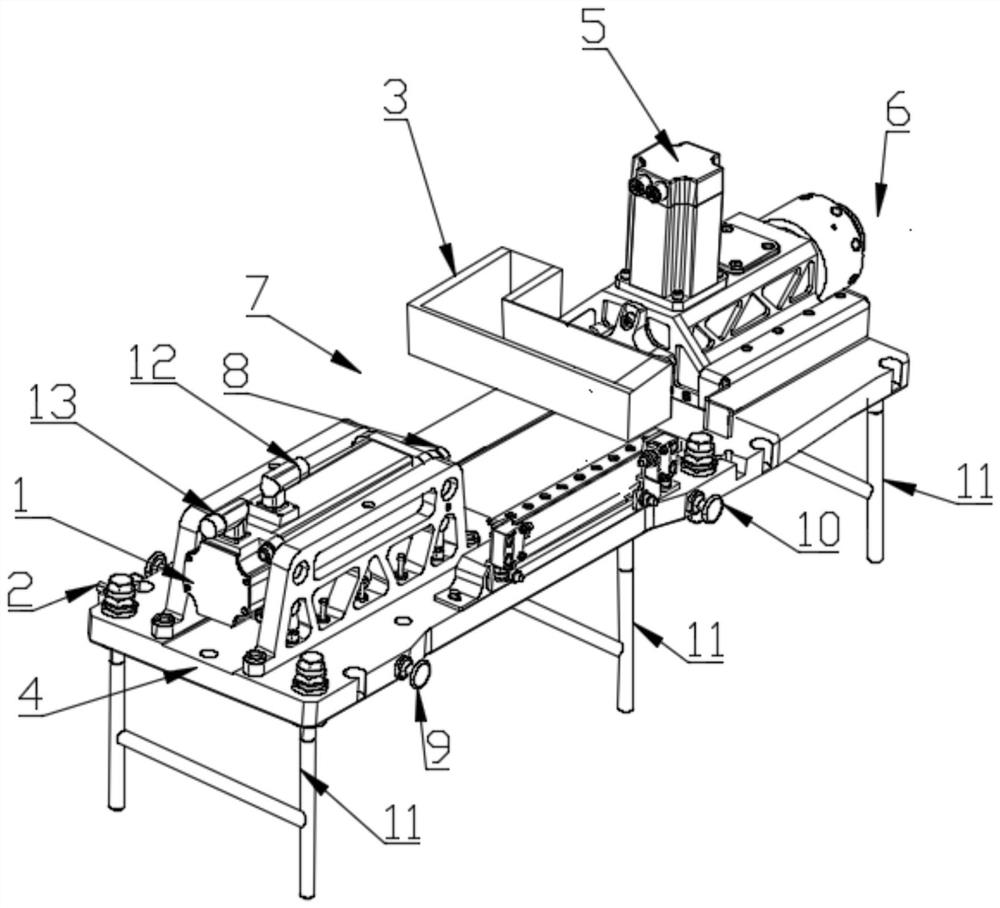

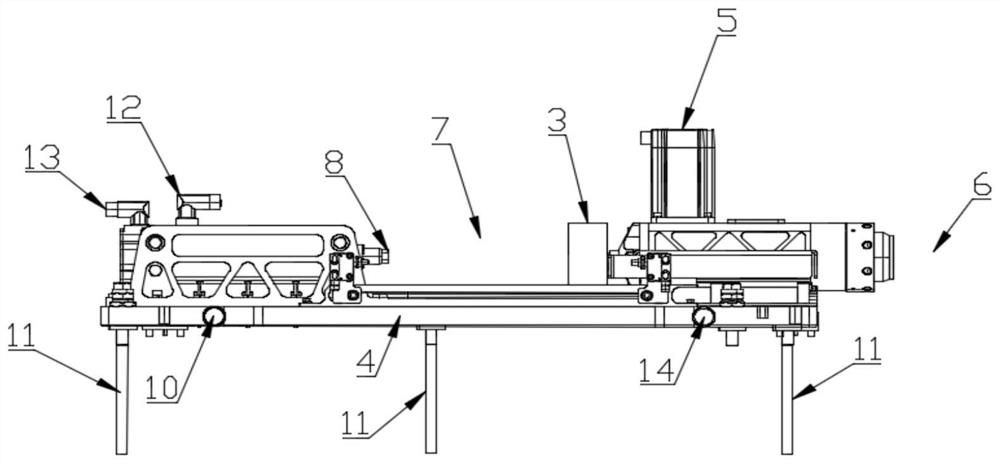

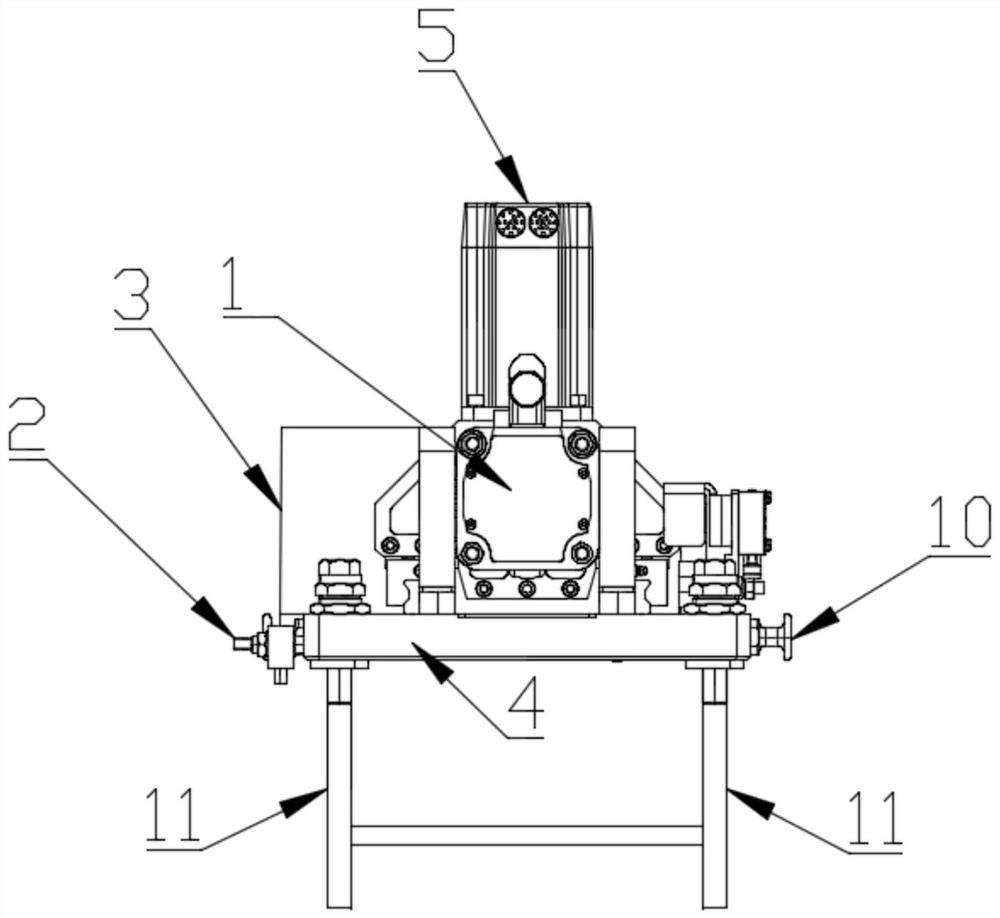

[0030] Embodiment 1: An intelligent extrusion machine includes a frame, an extrusion device, a mold delivery device 3, a hydraulic device, and an induction device. The frame includes several support frames 11 and a top frame 4, and each of the support frames 11 is arranged on one side of the top frame and is vertically fixedly connected with the top frame 4, the hydraulic device, the hydraulic device and the extrusion device are respectively arranged on both sides of the top frame, and the extrusion The pressing device includes an extruding rod 8 and a hydraulic pipeline, the hydraulic pipeline is fixedly connected with the hydraulic device and hydraulically driven, the extruding rod 8 is arranged in parallel with the top frame 4, and the induction device is respectively connected to the The pressure device is electrically connected with the hydraulic device. The extruding device comprises an extruding track, an extruding seat 26, an extruding rod 8 and a hydraulic traction de...

Embodiment 2

[0031]Embodiment 2: An intelligent extrusion machine includes a frame, an extrusion device, a mold delivery device 3, a hydraulic device, and an induction device. The frame includes several support frames 11 and a top frame 4, and each of the support frames 11 is arranged on one side of the top frame and is vertically fixedly connected with the top frame 4, the hydraulic device and the extruding device are respectively arranged on both sides of the top frame, and the extruding device includes extruding A rod 8 and a hydraulic pipeline, the hydraulic pipeline is fixedly connected with the hydraulic device and hydraulically driven, the extruding rod 8 is arranged in parallel with the top frame 4, and the induction device is connected with the extruding device and the Hydraulic unit electrical connection. Specifically, the extrusion device is fixedly connected to the top frame, and fixed plates are arranged on both sides of the extrusion device, and the fixed plates surround the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com