Method for controlling immersion depth of immersion nozzle

An immersion depth and immersion type technology, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of increased operating workload and high nozzle cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

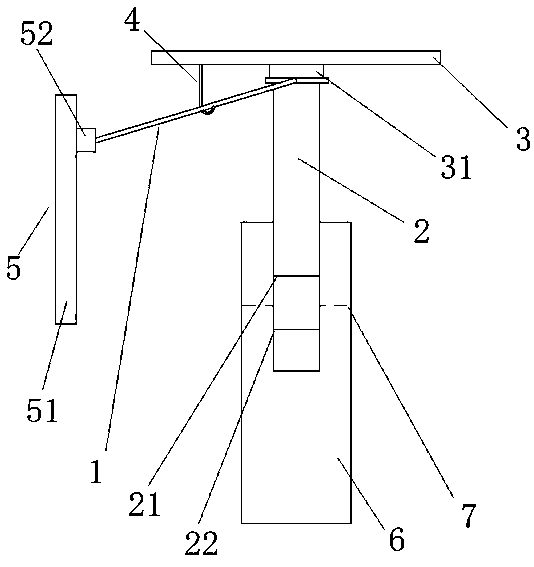

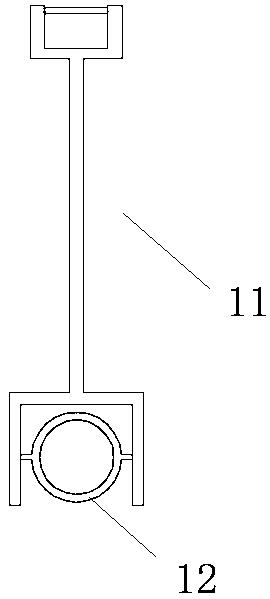

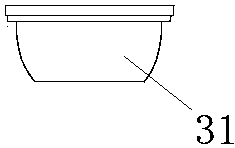

[0021] refer to Figure 1-3 , when the tundish is poured, the submerged nozzle 2 preheated to 1000°C is connected to the molten steel outlet 31 on the bottom plate 3 of the tundish through the clamping rod 1, and then the shaft 11 of the clamping rod 1 is placed in the tundish On the support member 4 of the bottom plate 3, the end of the clamping rod 1 away from the submerged nozzle is connected with a manipulator 5 for adjusting the height of the submerged nozzle 2, and an upper marking line 21 and a lower marking line 22 are provided on the submerged nozzle 2; When the type nozzle 2 enters the molten steel of the crystallizer copper tube 6, the molten steel surface 7 is located in the middle of the upper marking line 21 and the lower marking line 22 on the submerged nozzle 2 by adjusting the height of the tundish, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com