A kind of preparation method of plastic machine rubber roller

A technology for laminating machines and rubber rollers, which is applied to chemical instruments and methods, rubber layered products, and other household appliances. Large changes in contact pressure, lower operating temperature, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

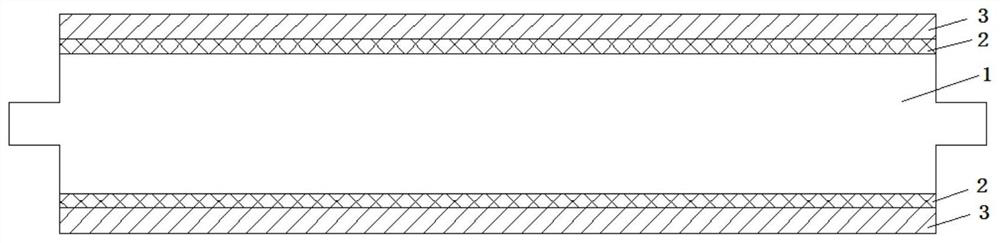

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 plastic machine rubber roller material

[0027] The rubber roller material of the plastic machine is non-foaming rubber material

[0028] The weight ratio of the non-foaming rubber material is: 225 parts of methyl vinyl silicone raw rubber; 112.5 parts of precipitated silica; 3.5 parts of hydroxyl silicone oil; 1.2 parts of hydrogen-containing silicone oil; 6.0 parts of dimethyl silicone oil; 3.5 parts of dimethyldiethoxysilane; 2.5 parts of internal release agent; 100 parts of silicon micropowder; 2.0 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane.

[0029] The preparation method of the non-foaming rubber material: methyl vinyl silicone raw rubber, precipitated silica, hydroxyl silicone oil, hydrogen-containing silicone oil, dimethyl silicone oil, dimethyldiethoxysilane, internal mold release agent , microsilica powder and 2,5-dimethyl-2,5-di-tert-butylperoxyhexane are placed in a double-roll mill and mixed evenly to obtain the non...

Embodiment 2

[0031] Embodiment 2 Preparation of rubber roller material for plastic machine

[0032] The rubber roller material of the plastic machine is non-foaming rubber material

[0033] The weight ratio of the non-foaming rubber material is: 225 parts of methyl vinyl silicone raw rubber; 112.5 parts of precipitated silica; 3.5 parts of hydroxyl silicone oil; 1.2 parts of hydrogen-containing silicone oil; 6.0 parts of dimethyl silicone oil; 3.5 parts of dimethyldiethoxysilane; 2.5 parts of internal mold release agent; 100 parts of modified silica powder; 2.0 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane;

[0034] The modified silicon micropowder is prepared by the following method: Soak the silicon micropowder in an aqueous solution containing polyethyleneimine with a molecular weight of 70,000 and polydimethyldiallyl ammonium chloride with a molecular weight of 300,000 for 12 hours. Dry to obtain the modified silica powder; the mass fraction of polyethyleneimine in the aqueous s...

Embodiment 3

[0049] Embodiment 3 Preparation of rubber roller material for plastic machine

[0050] The rubber roller material of the plastic machine is foam rubber material

[0051] The weight ratio of the non-foaming rubber material is: 225 parts of methyl vinyl silicone raw rubber; 112.5 parts of precipitated silica; 3.5 parts of hydroxyl silicone oil; 1.2 parts of hydrogen-containing silicone oil; 6.0 parts of dimethyl silicone oil; 3.5 parts of dimethyldiethoxysilane; 2.5 parts of internal release agent; 100 parts of silicon micropowder; 2.0 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane; closed-cell foaming 8 doses;

[0052] The preparation method of the non-foaming rubber material: methyl vinyl silicone raw rubber, precipitated silica, hydroxyl silicone oil, hydrogen-containing silicone oil, dimethyl silicone oil, dimethyldiethoxysilane, internal mold release agent , microsilica powder, 2,5-dimethyl-2,5-di-tert-butylperoxyhexane and closed-cell foaming agent are placed in a d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap