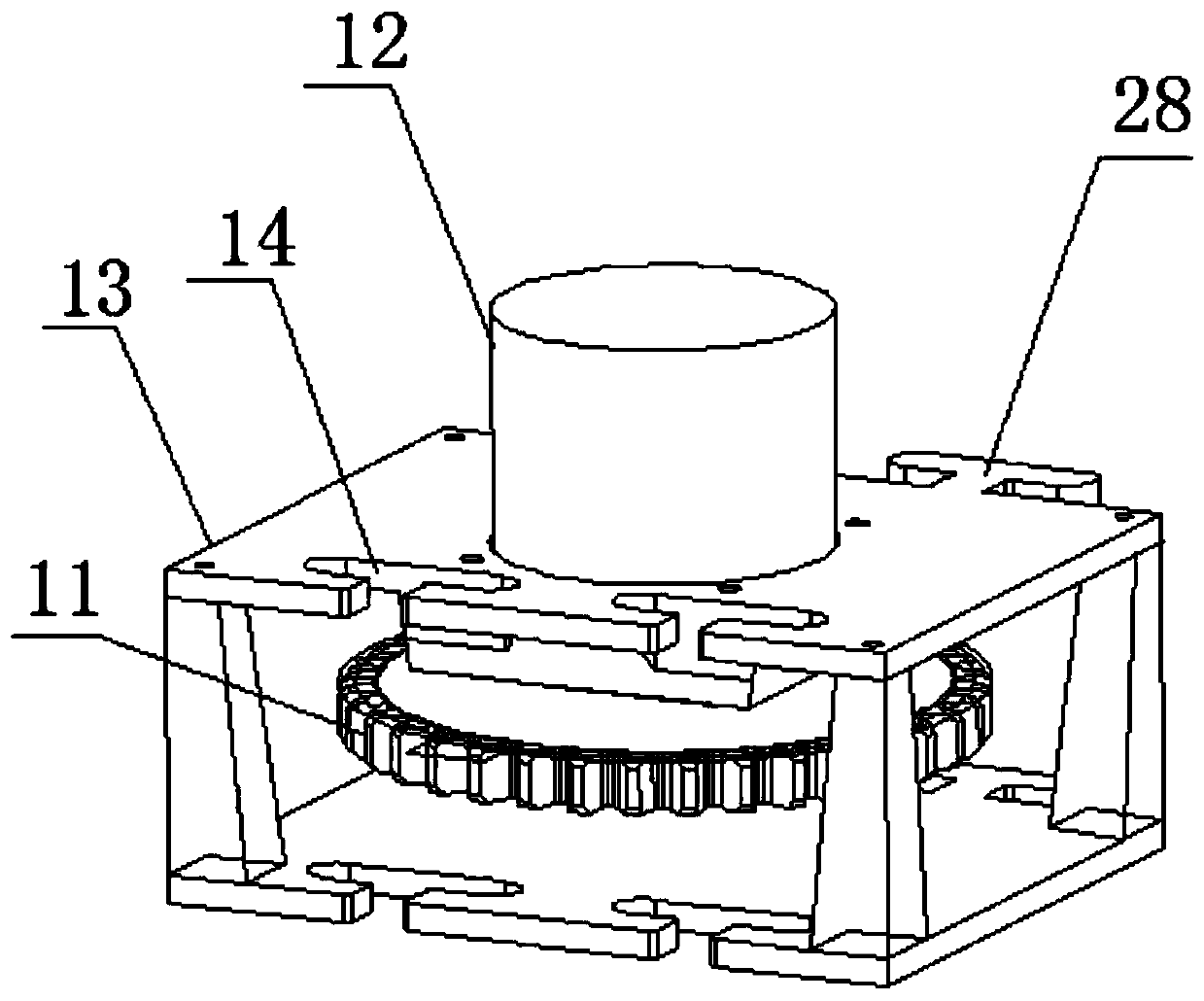

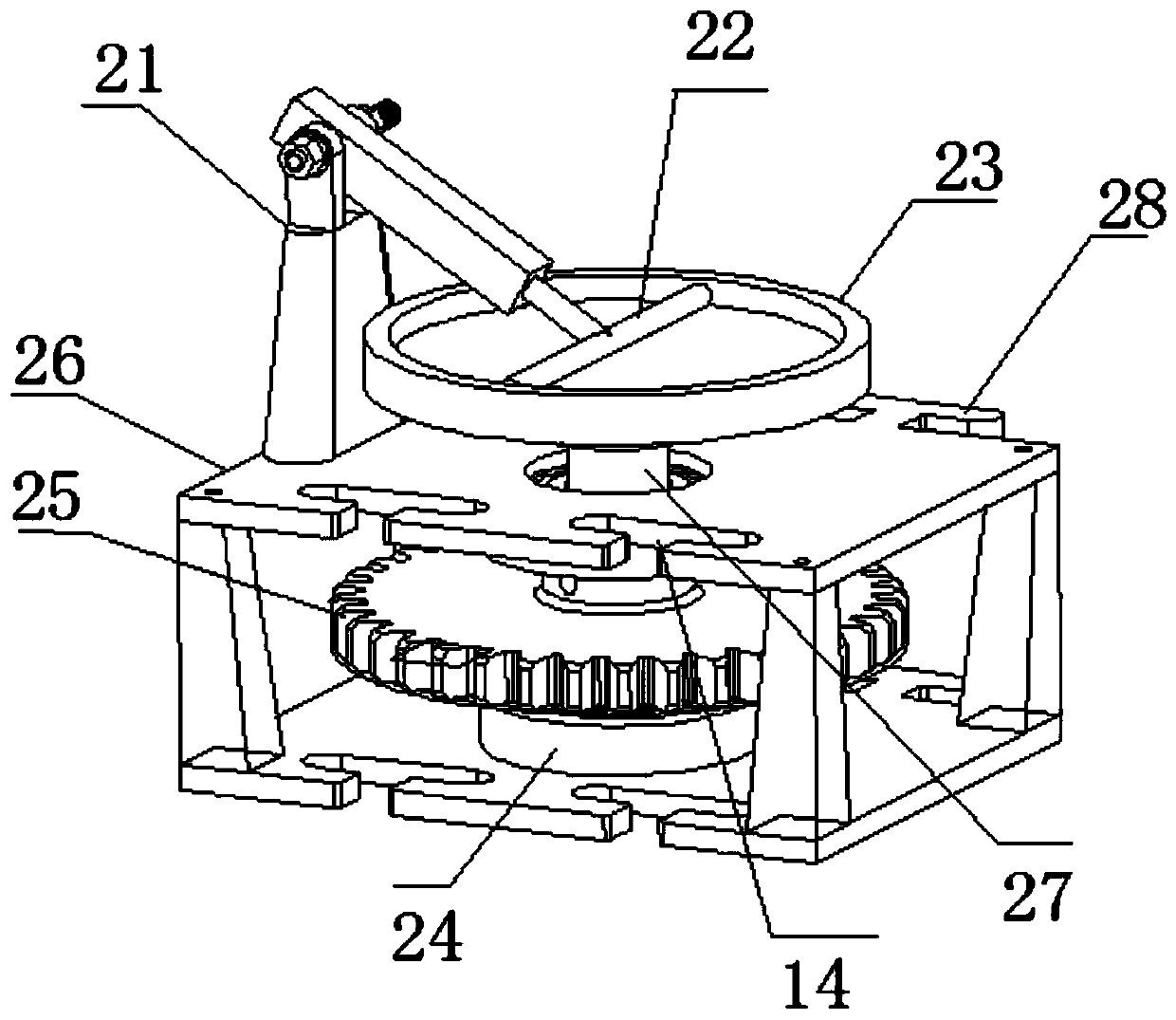

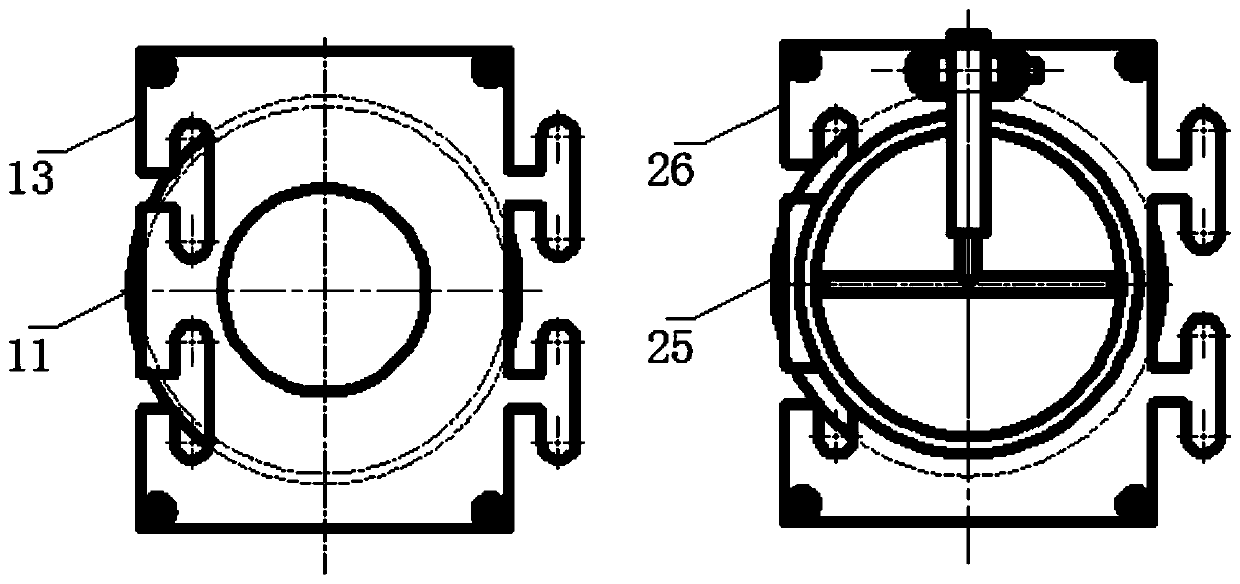

Modular flat coating device

A coating device and modular technology, applied in biochemical instruments, biochemical equipment and methods, biological material sampling methods, etc., can solve the problems of inefficiency, density, inability to count and observe the characteristics of colonies, and achieve the solution efficiency. Low, the effect of improving the coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] In the present invention, in the absence of relevant explanations, the used orientation words such as "upper, lower, top, bottom" are usually for the direction shown in the drawings or for the vertical, vertical or gravitational direction The terms used to describe the mutual positional relationship of the various components mentioned above.

[0035] The use of the words first, second, and third, etc. does not indicate any order. These words can be interpreted as names.

[0036] The word "a" or "an" preceding an element does not exclude the presence of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com