A telescopic pipeline flow generator

A pipeline flow and generator technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve natural environmental pollution, limited battery life, economic loss, etc. problems, to achieve the effects of strong environmental adaptability, effective frequency bandwidth, and strong power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

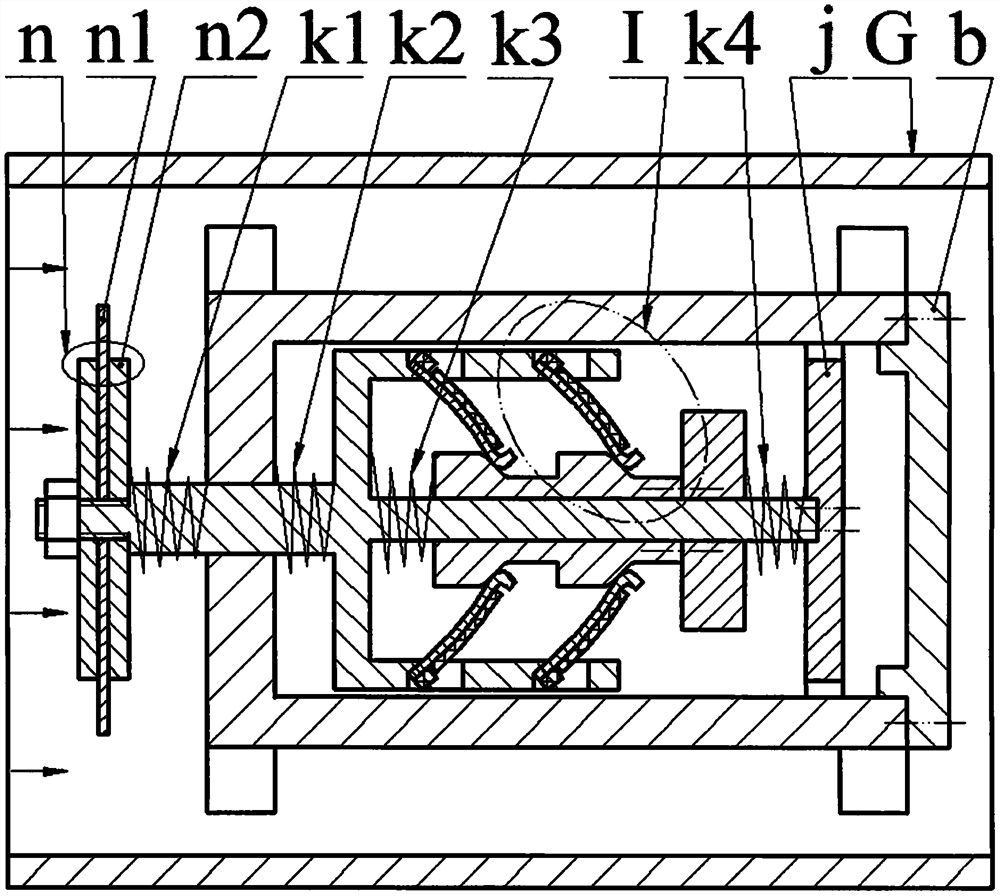

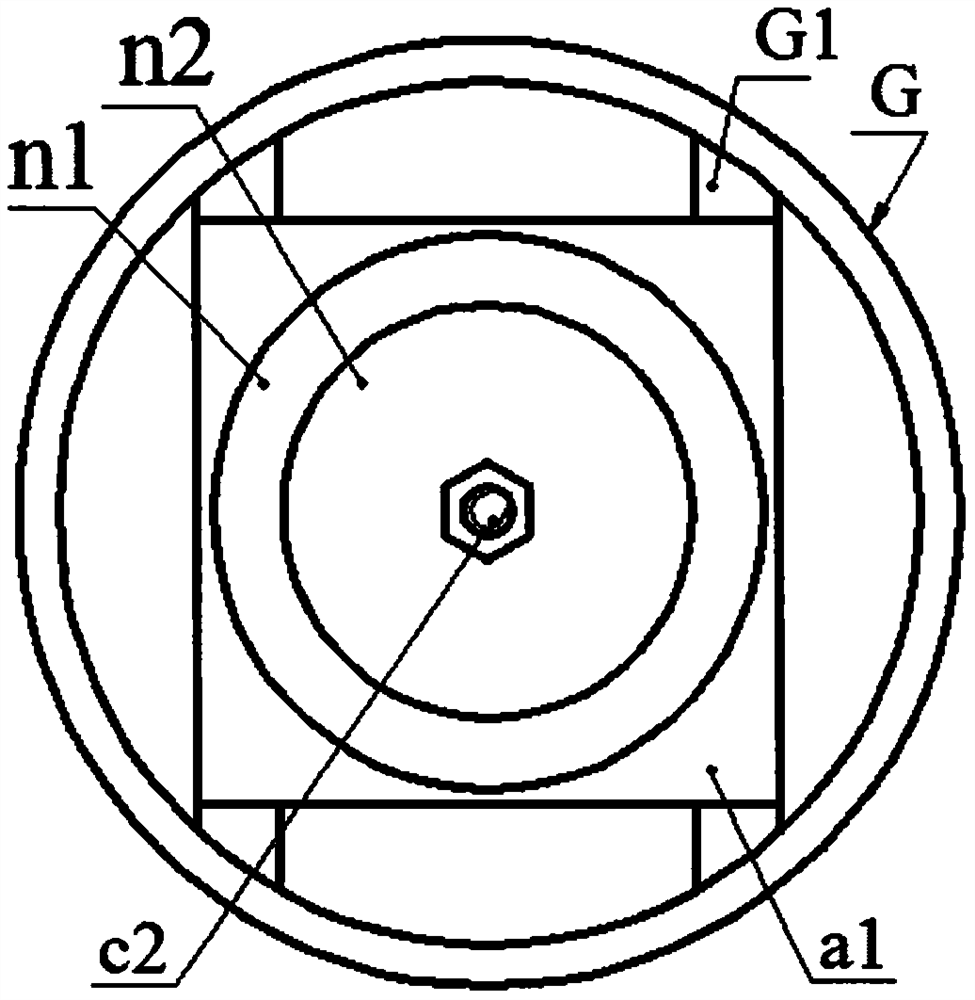

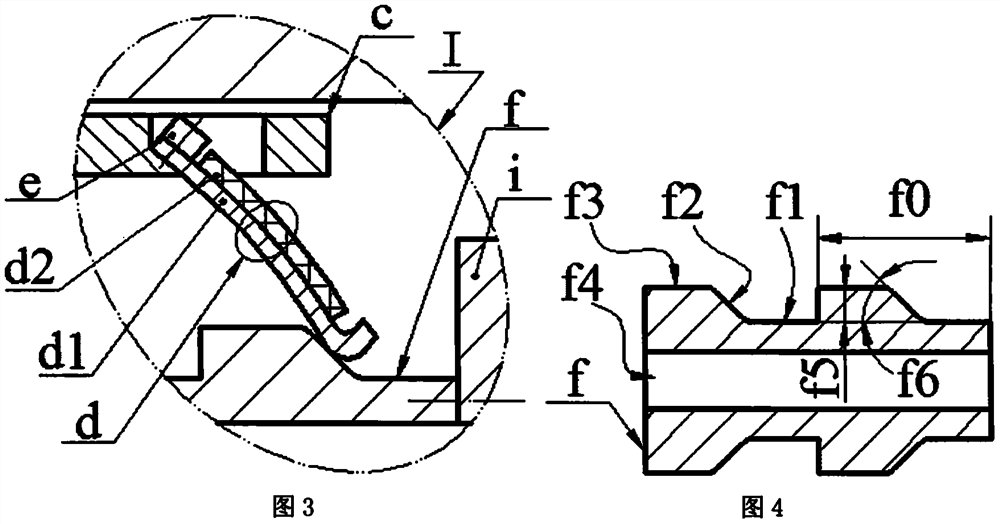

[0014] On the inner wall of the pipe G, a shell a is installed through the radial plate G1, and the end of the side wall a2 of the shell a is installed with an end cover b through screws; the left and right pins of the vertical plate c1 of the bracket c are respectively provided with a left pin c2 and a right pin c3, the left pin c2 and the right pin c3 are coaxial, and the cross sections of the left pin c2 and the right pin c3 are circular and square, respectively; There is an inclined installation surface c5, the installation surface c5 is located on the hole wall on the horizontal plate c4, the acute angle c6 formed by the installation surface c5 and the horizontal plate c4 is the installation angle, and the installation angle is greater than 30 degrees; the bracket c is placed in the body cavity of the shell a Inside a3 and the left pin c2 protrudes through the guide hole on the bottom wall a1 of the shell. The end of the left pin c2 is installed with a blunt body n through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com