Crankshaft front end oil seal tool capable of precisely positioning and pressing

A technology of precise positioning and front oil seal, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of difficult to ensure the concentricity between the center hole of the oil pump and the center of the crankshaft, oil leakage of the oil seal before the curve, etc., to achieve simple structure and improve work efficiency. Efficient, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

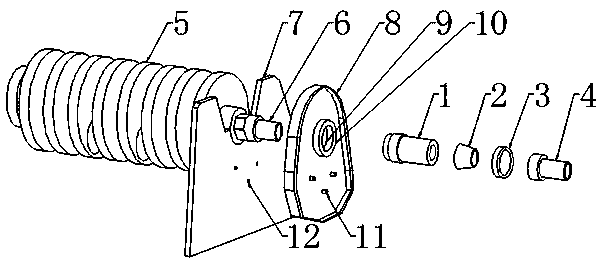

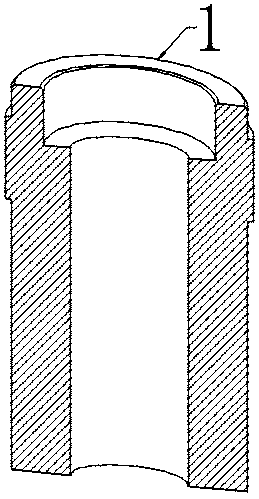

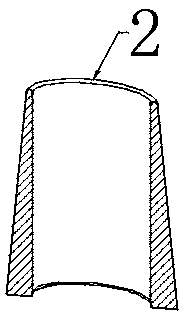

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, a precise positioning and pressing front oil seal tooling is composed of an oil pump positioning sleeve 1, an oil seal positioning sleeve 2 and an oil seal pressure head 4. The oil pump positioning sleeve 1 is set on the crankshaft front end 6 of the engine crankshaft 5. For positioning the oil pump, the front end 6 of the crankshaft passes through the center hole 10 of the oil pump 8, and the oil pump positioning sleeve 1 passes through the center hole 10 of the oil pump 8 and is set on the front end 6 of the crankshaft, and an oil seal groove 9 is opened in the center hole 10 , the front crank oil seal 3 is installed in the oil seal groove 9, the front crank oil seal 3 is positioned by the oil seal positioning sleeve 2, the front crank oil seal 3 is installed by the oil seal head 4, and the front end of the crankshaft 6 is a stepped shaft composed of an inner shaft and an outer ...

Embodiment 2

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, a precise positioning and pressing front oil seal tooling is composed of an oil pump positioning sleeve 1, an oil seal positioning sleeve 2 and an oil seal pressure head 4. The oil pump positioning sleeve 1 is set on the crankshaft front end 6 of the engine crankshaft 5. For positioning the oil pump, the front end 6 of the crankshaft passes through the center hole 10 of the oil pump 8, and the oil pump positioning sleeve 1 passes through the center hole 10 of the oil pump 8 and is set on the front end 6 of the crankshaft, and an oil seal groove 9 is opened in the center hole 10 , the front crank oil seal 3 is installed in the oil seal groove 9, the front crank oil seal 3 is positioned by the oil seal positioning sleeve 2, the front crank oil seal 3 is installed by the oil seal head 4, and the front end of the crankshaft 6 is a stepped shaft composed of an inner shaft and an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com