Double plus chain conveyor

A conveyor and double-speed chain technology, applied in the field of production equipment, can solve the problems of high requirements on the fuselage bearing beam and installation space, inconvenient installation and maintenance, complex overall structure, etc., to achieve improved life, convenient use and maintenance, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

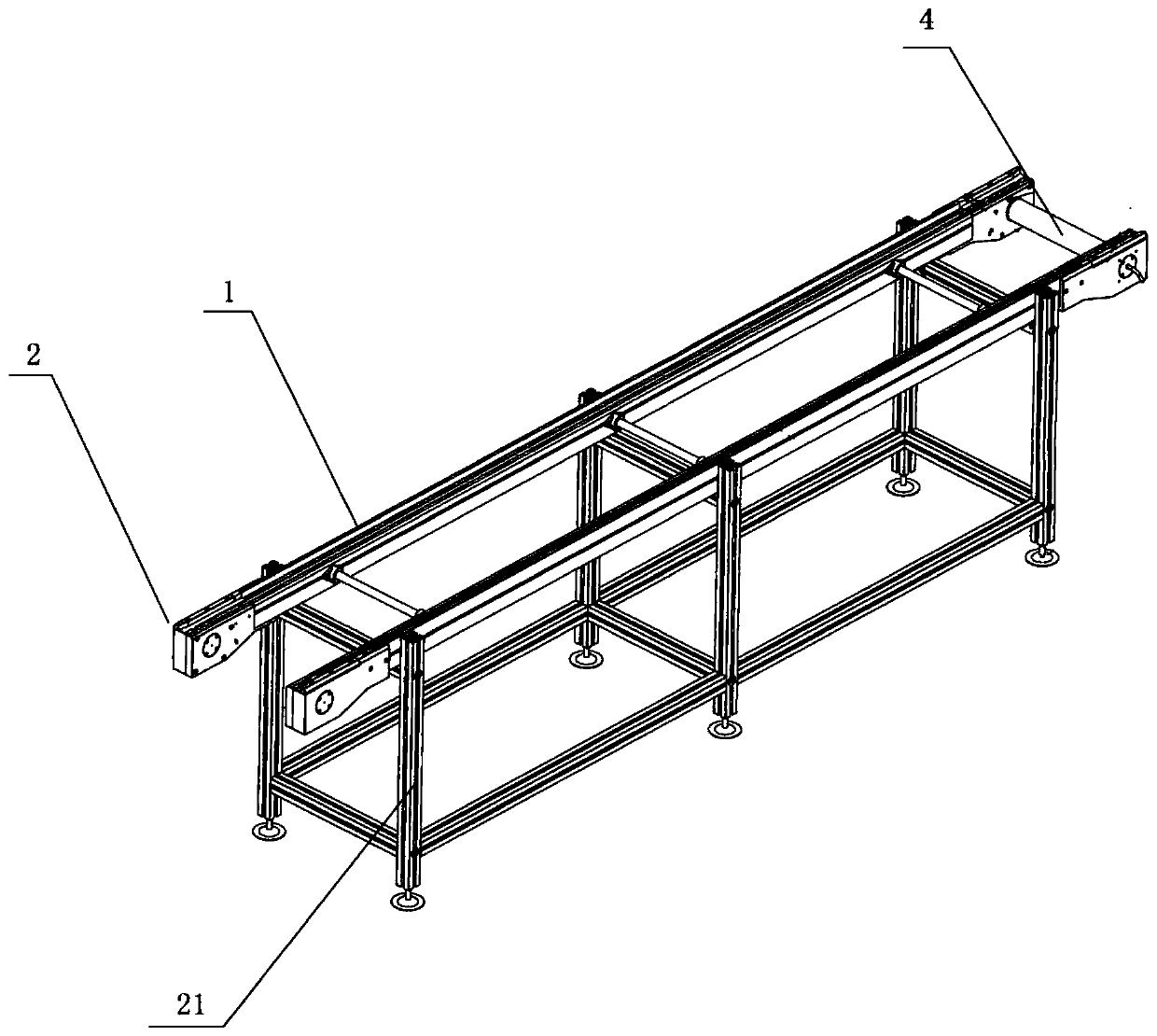

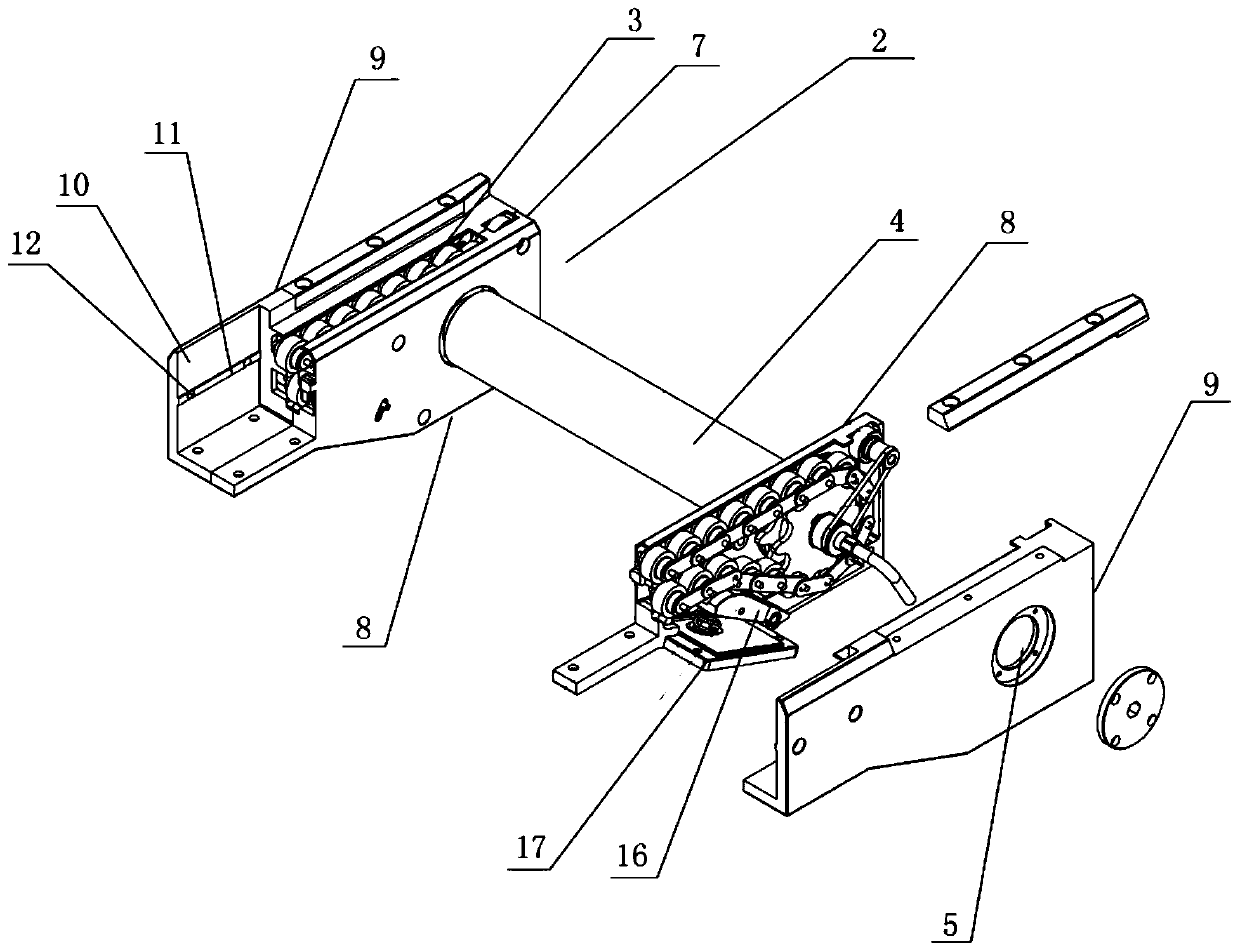

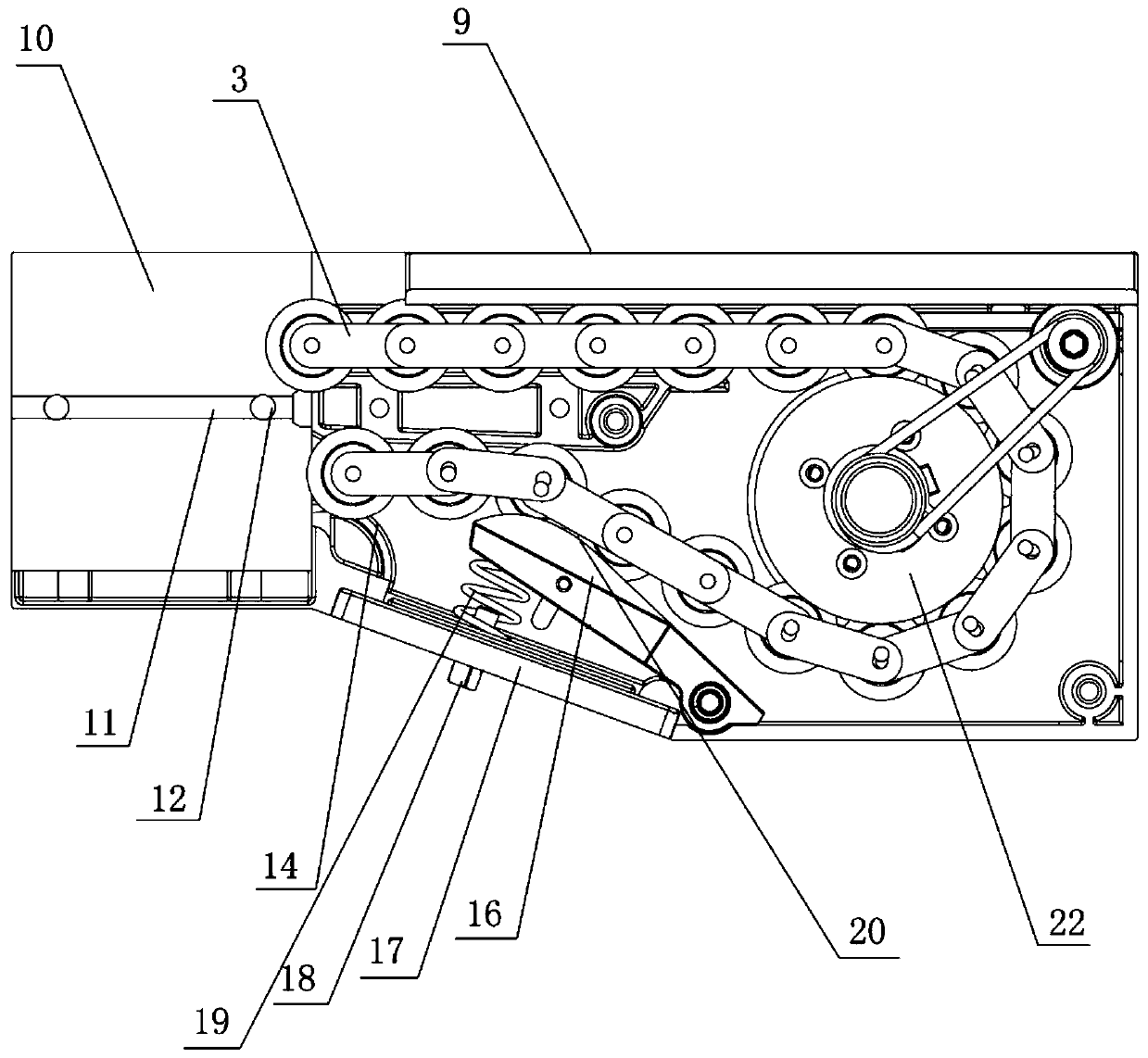

[0028] Embodiment one: see Figure 1-7 As shown, a double-speed chain conveyor includes a fuselage 1. The fuselage 1 is extruded from an aluminum profile and includes an upper channel and a lower channel. The fuselage 1 is provided with a wear-resistant guide rail. The body 1 is installed on the support frame, and a group of end modules 2 are respectively connected to both ends of the body 1, and the end modules 2 at both ends of the body 1 are designed to have the same structure, which is convenient for installation and interchangeable. Strong versatility;

[0029] Each set of end modules 2 includes a pair of symmetrically arranged first and second fixed shells;

[0030] The fuselage 1 and the first fixed shell and the second fixed shell connected to the two ends of the fuselage 1 are provided with a double-speed chain 3, and the double-speed chain 3 forms a ring structure inside; the double-speed chain 3 The chain rollers adopt special high-strength wear-resistant nylon ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com