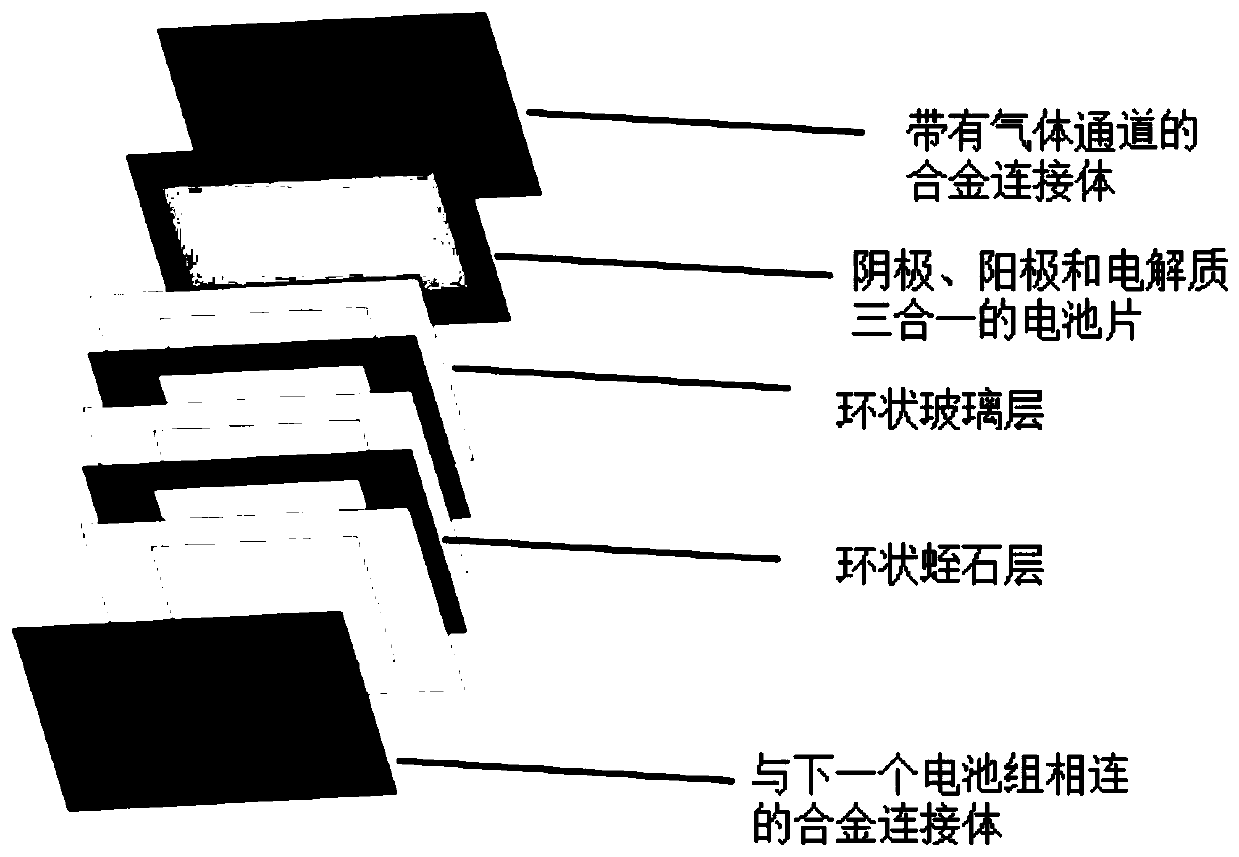

A kind of glass-vermiculite composite sealing material and its preparation method and application

A sealing material and vermiculite technology, which is applied in mechanical equipment, engine sealing, sealing/supporting devices, etc., can solve the problems of poor air tightness and limit the application range of glass materials, etc., achieve good sealing effect and improve power generation Efficiency, service life, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

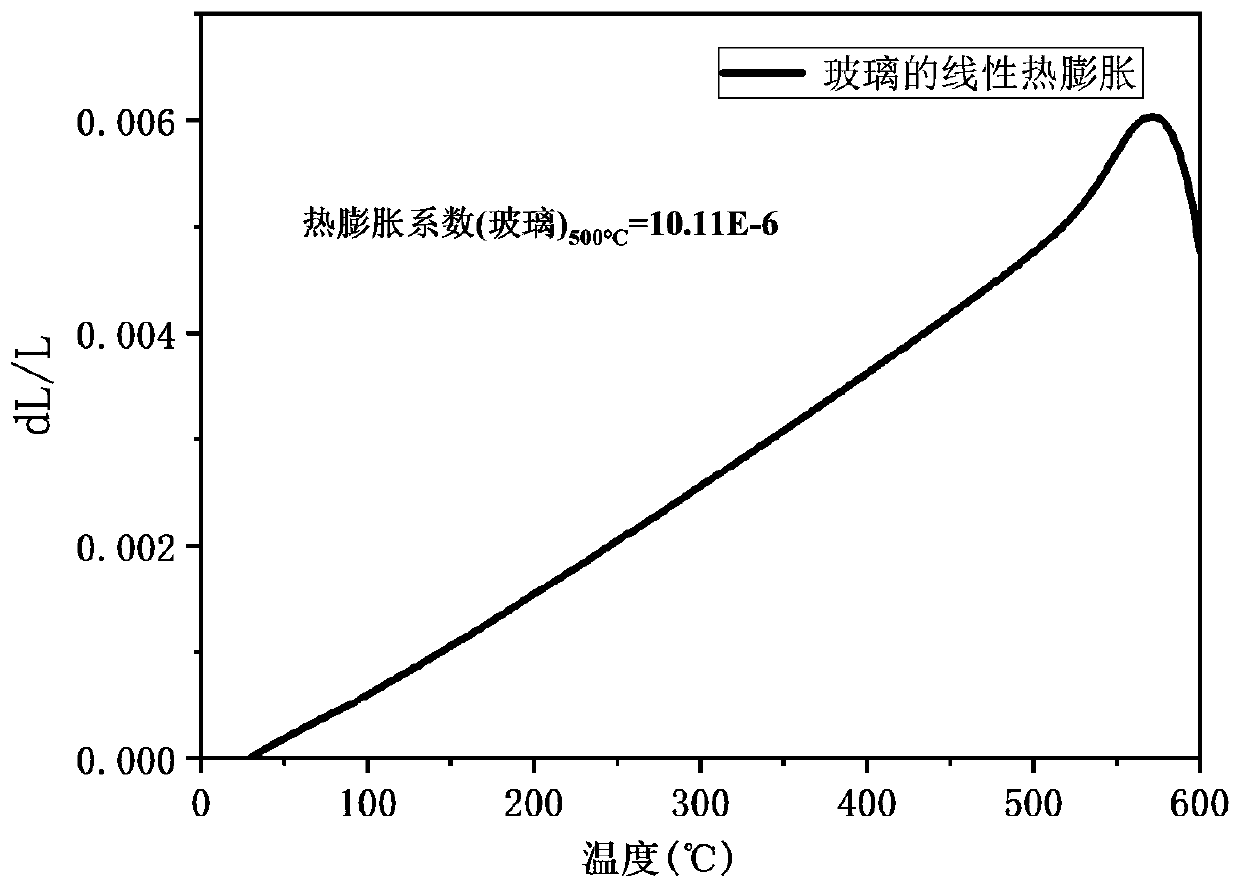

Embodiment 1

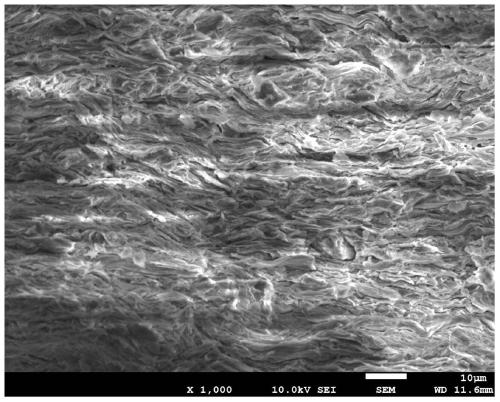

[0047] (1) Grinding: The glass composition and content used are SiO 2 70.4 wt%, K 2 O 10.5wt%, Na 2 O6.5wt%, CaO 4.3wt%, BaO 2.2wt%, MgO 1.3wt%, TiO 2 1.2wt%, the rest is Fe 2 o 3 , the softening temperature of the glass is lower than 650°C, and its thermal expansion is as follows figure 2 As shown, the coefficient of thermal expansion of glass at a temperature of 30-600°C is (8.4-11.2)×10 -6 K -1 ; The glass powder is calcined at high temperature to form a molten body, then crushed and ground after quenching and quenching, adding ethanol and zirconia balls for ball milling for more than 12 hours, drying after ball milling and passing through a 200-mesh sieve to obtain glass powder, and preliminarily crushing the vermiculite Then add ethanol and zirconia balls to grind for more than 18 hours, then dry and pass through a 200-mesh sieve to obtain vermiculite powder;

[0048] (2) Molding: cast the glass powder and vermiculite powder in the process (1) separately, specif...

Embodiment 2

[0055] Other steps are the same as in Example 1, the difference is that the vermiculite powder used in the step (2) is preheated, and the specific pretreatment is that the vermiculite powder is heated to 900° C. for 60 minutes with a 2° C. / min muffle furnace, and then heated at 2° C. / min cooling rate down to room temperature.

[0056] The resulting composite sealing material ring was cut according to the same method as in Example 1, placed, and tested under the same battery test conditions, Figure 7 It is the stability of the open circuit voltage during the battery test in Example 2. The open circuit voltage (OCV) of the single battery tested at 750°C has no obvious attenuation in the 6 thermal cycle tests of the temperature rising to 750°C and cooling to 100°C. The test time exceeds 2500min, and the OCV remains above 1.05V.

Embodiment 3

[0058] Other steps are the same as in Example 2, except that a five-layer composite sealing material of glass-vermiculite-glass-vermiculite-glass is finally obtained, with a thickness of about 3.1mm.

[0059] The obtained composite sealing material ring was cut according to the same method as in Example 1, placed, and tested under the same battery test conditions. The open circuit voltage (OCV) of the single cell tested at 750°C experienced a temperature rise of 750°C and a temperature drop of 100°C. The OCV of the battery has no obvious decay in the 8 thermal cycle tests, and the cumulative test time exceeds 3000min, and the OCV remains above 1.05V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com