A method for annealing and degreasing large-width double-sided glossy aluminum foil

A large-width, aluminum foil technology, applied in the field of large-width double-sided smooth aluminum foil annealing and degreasing, can solve the problem of insufficient degreasing, and achieve the effects of reducing energy consumption, facilitating overflow, and equalizing negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

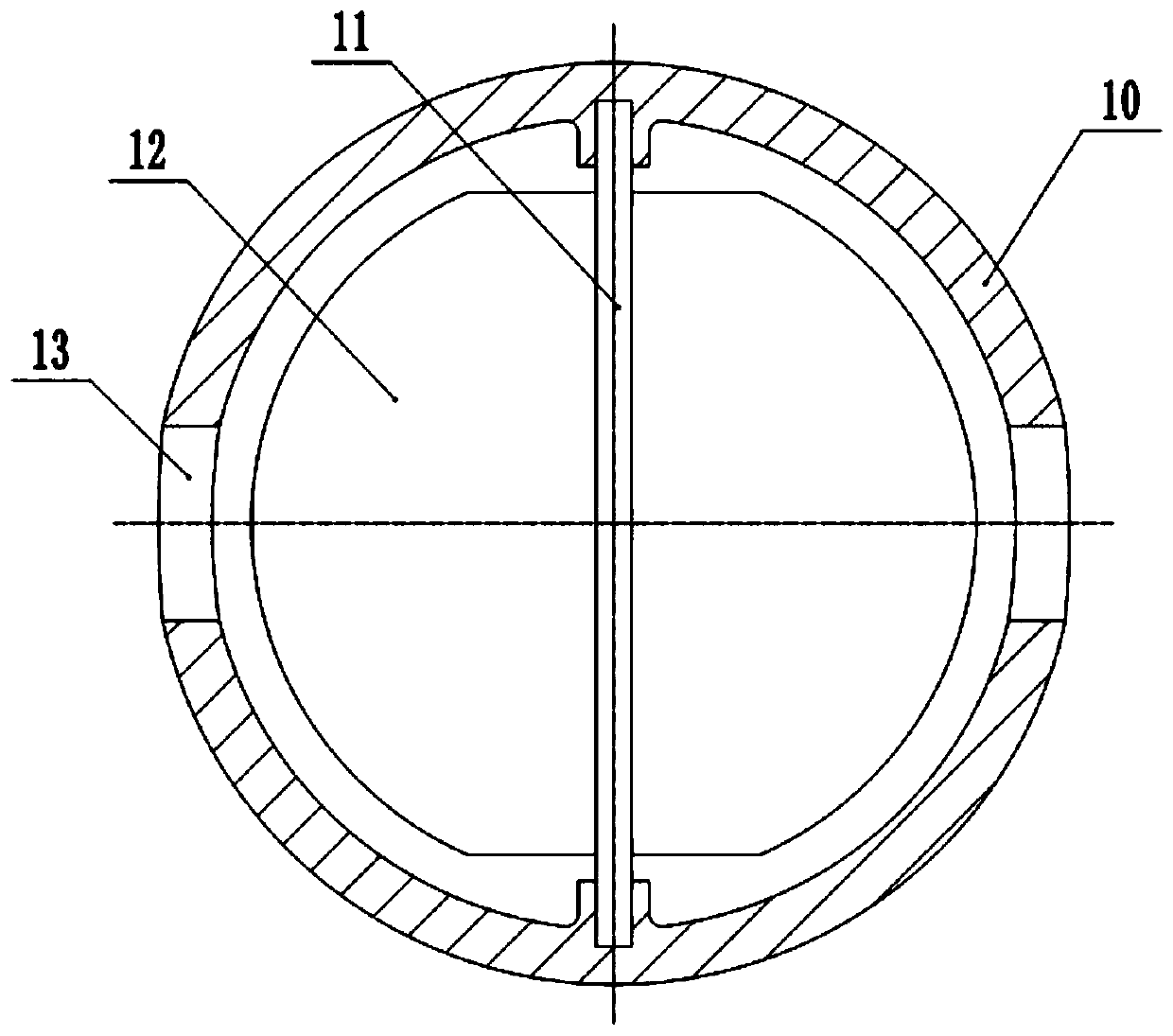

[0029] The reference signs in the accompanying drawings of the specification include: an air outlet pipe 10 , a vertical shaft 11 , a buffer plate 12 , and an air outlet hole 13 .

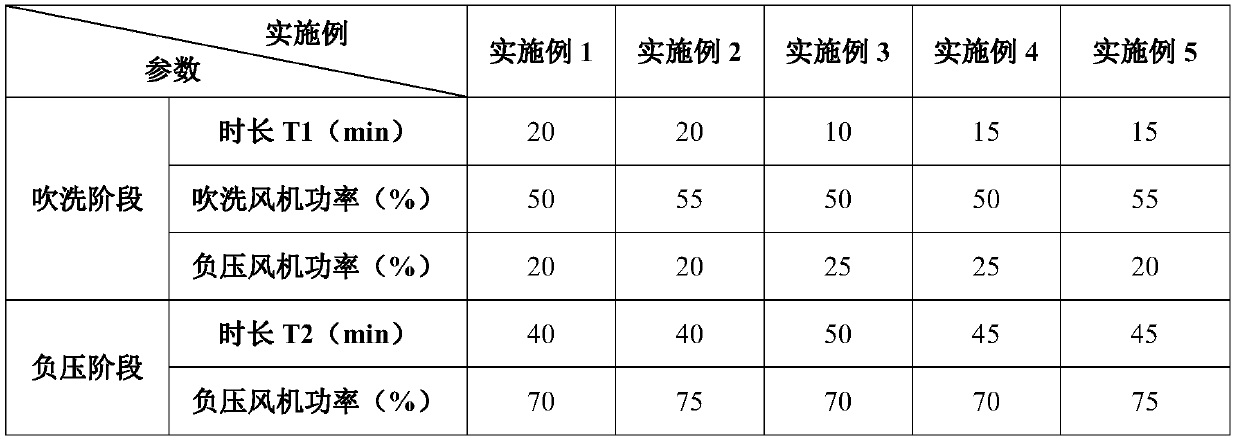

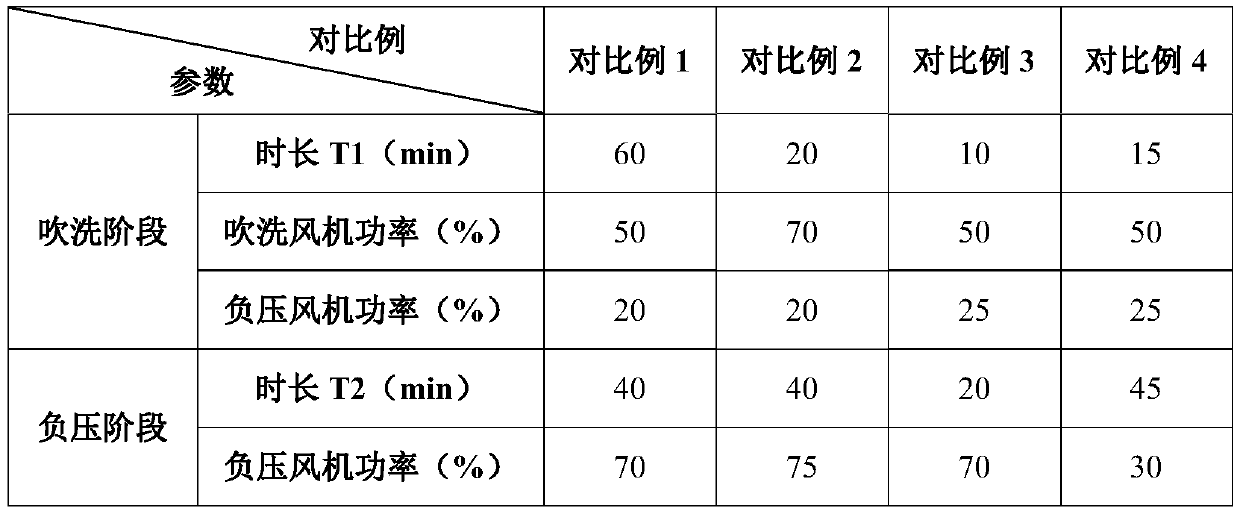

[0030] The parameter of embodiment 1-5 is as shown in table 1 below:

[0031] Table 1 is the parameters of Examples 1-5 of a large-width double-sided aluminum foil annealing and degreasing method

[0032]

[0033] Taking Example 1 as an example below, a method for annealing and degreasing a large-width double-sided glossy aluminum foil is described in detail:

[0034] The annealing of aluminum foil in the annealing furnace mainly includes the following stages: heating stage, oil removal and heat preservation stage, continuous heating stage, performance heat preservation stage, cooling stage, and low temperature heat preservation stage, in which the aluminum foil is degreased in the oil removal and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com