Nacelle structure type lubricating oil tank

A lubricating oil tank, structural technology, applied in the direction of engine lubrication, turbine/propulsion device lubrication, engine components, etc., can solve the problems of difficult layout, oil tank rotor containment, heavy weight, etc., to save weight and space, reduce The effect of design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

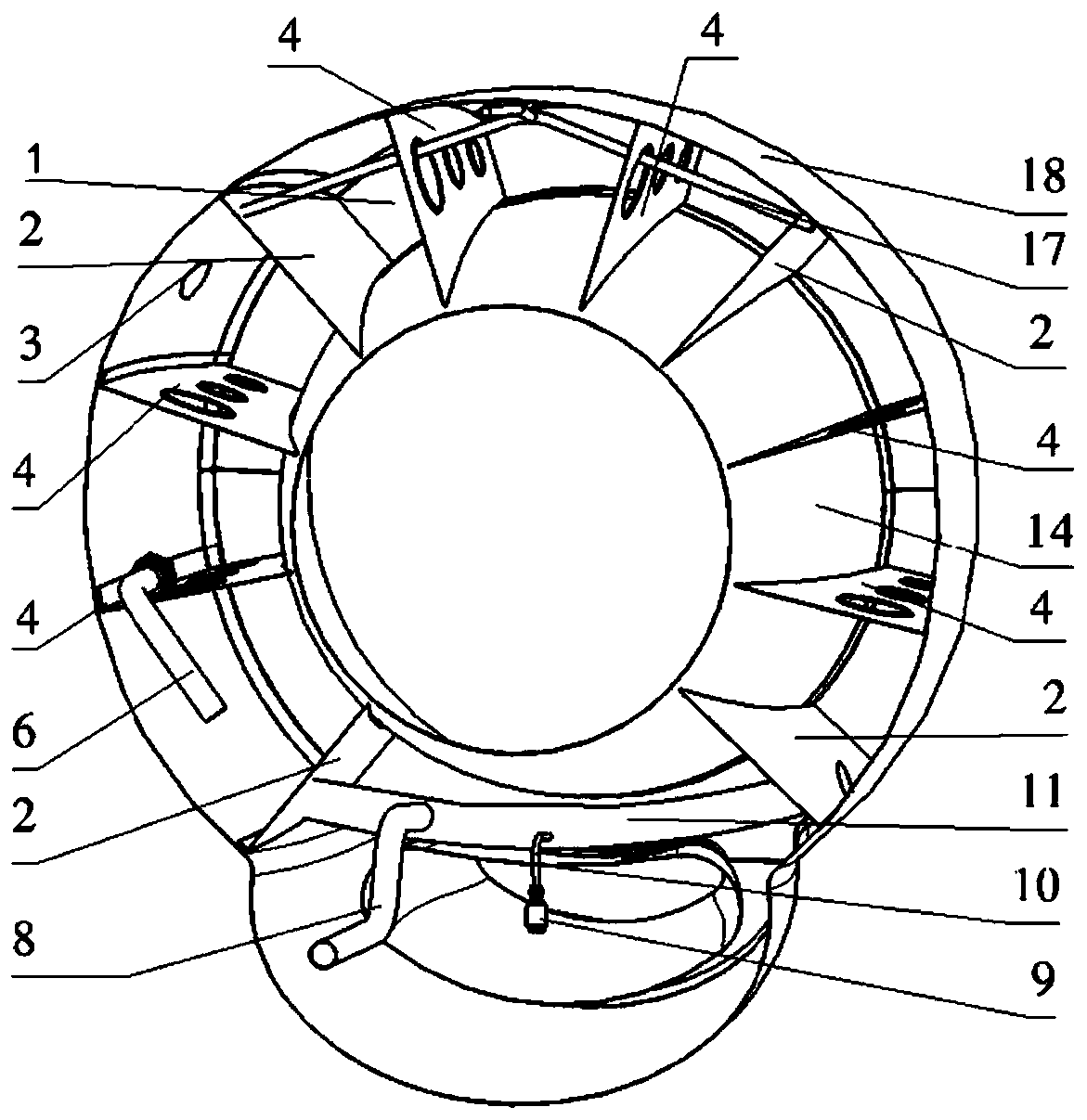

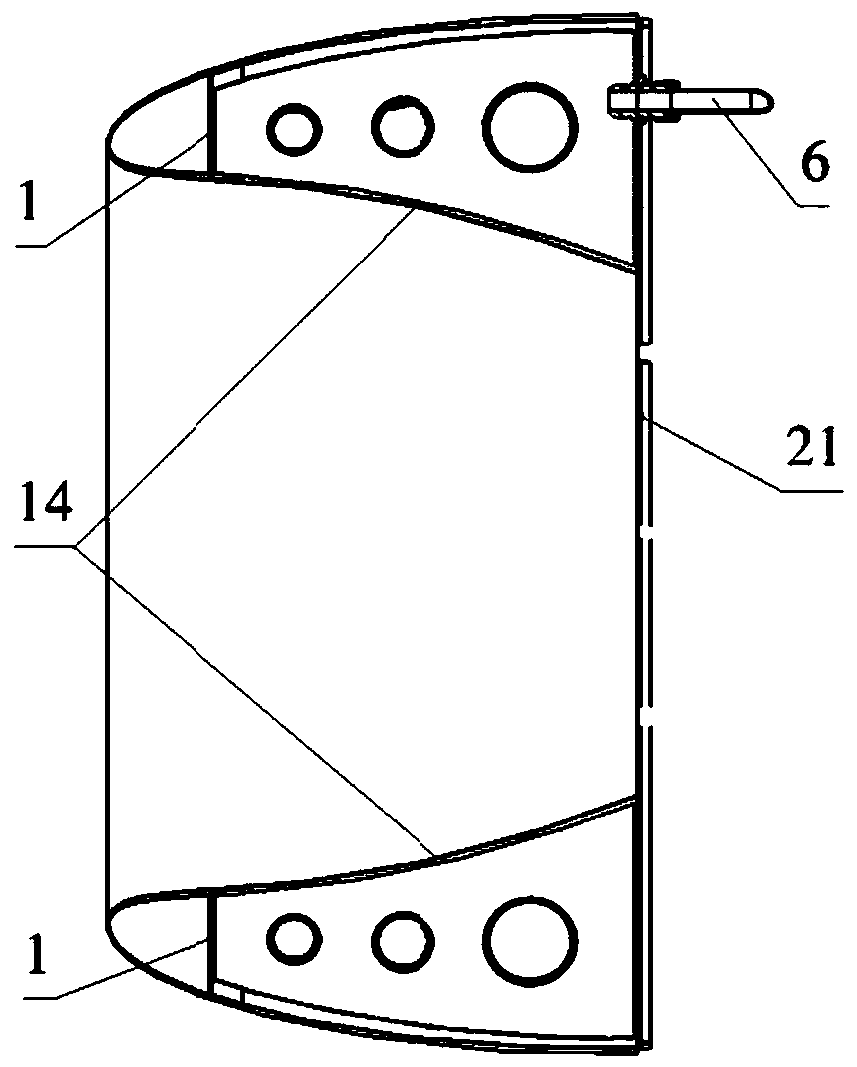

[0021] In practical applications, the integrated lubricating oil tank is located in the designated fire zone of the aircraft, and the design requirements are high and difficult. In the front of the engine nacelle, since the reducer of the engine is usually relatively small in size, there is a large space between the engine and the nacelle skin, which will not be affected by the rotor. This area does not belong to the designated fire zone. No structural oil tank is designed in the engine nacelle.

[0022] When lubricating oil is added through the filling port 3, the lubricating oil enters the lubricating oil tank, and the left and right sides are kept refueling at the same time through the connecting pipe 11 and the vent pipe 17, and the liquid level is consistent;

[0023] The gap provided on the edge of the support partition 4 should be located at the bottom to prevent the occurrence of dead oil; Riveted and glued.

[0024] The diameter of the connecting pipe 11 should not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com