A system for recovering, storing and utilizing vaporized gas in liquid cargo tanks by using tube-bundle high-pressure gas cylinders

A high-pressure gas cylinder and tube-bundle technology, applied in the system field, can solve problems such as poor economy, waste of resources, inflammability and explosion, etc., and achieve the effects of reducing construction costs, saving natural gas, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

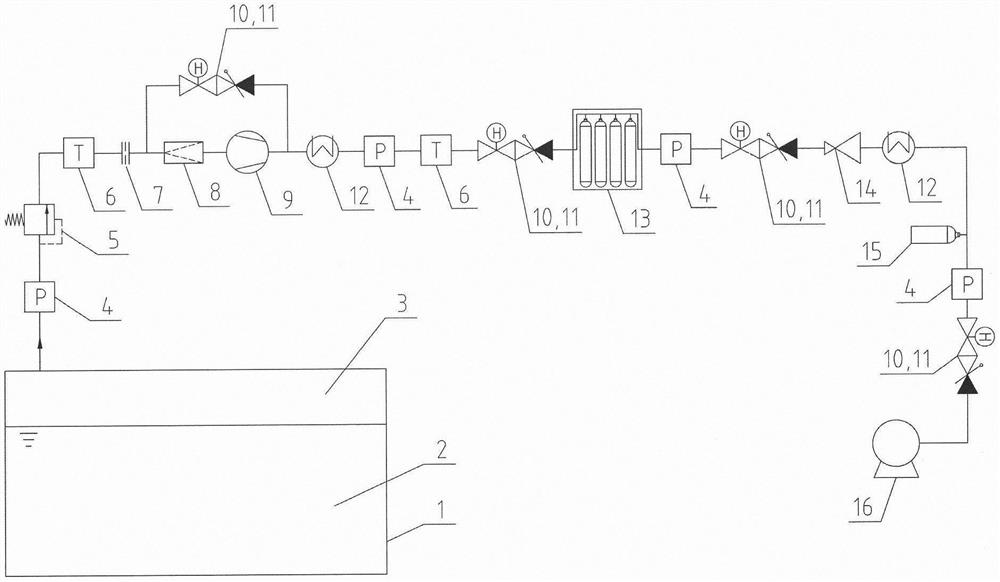

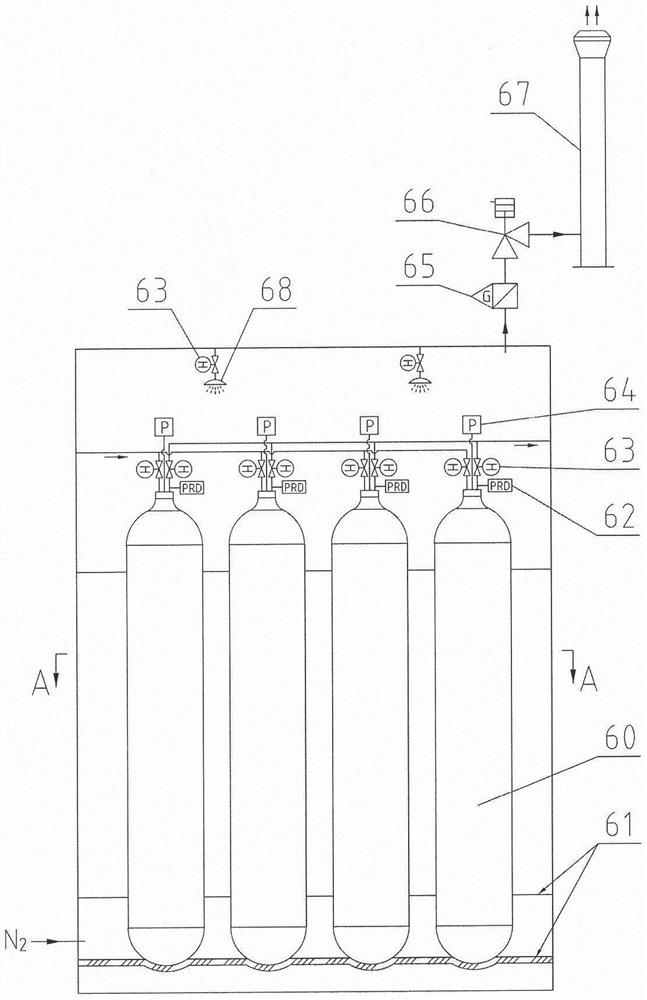

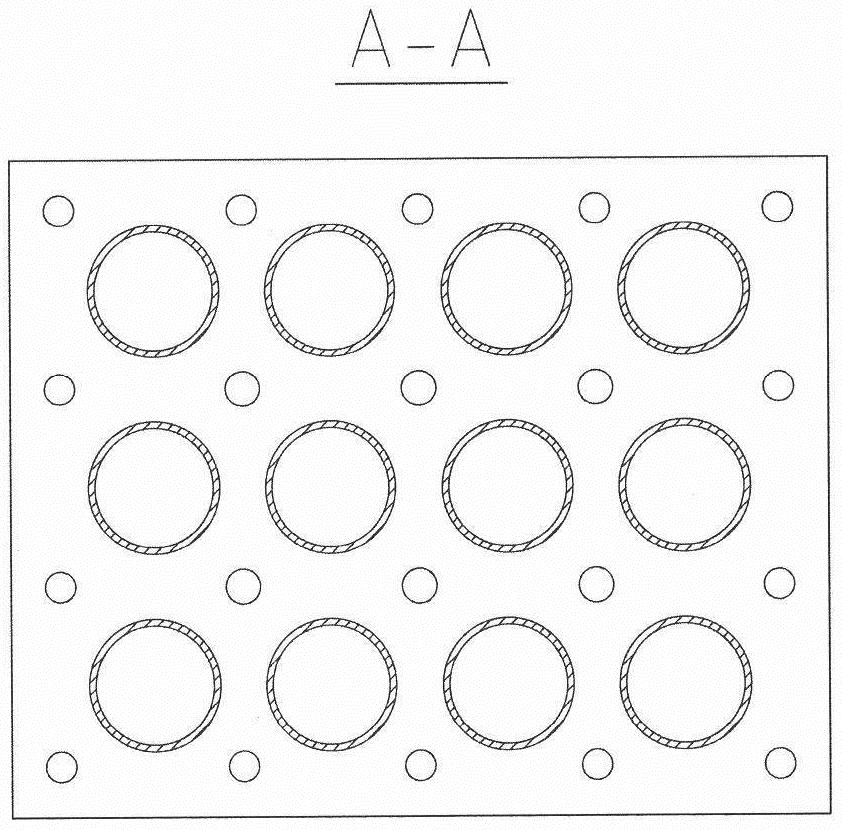

[0030] see figure 1 Shown is a system for recovering, storing and utilizing LNG ship cargo tank boil-off gas with a tube bundle type high pressure gas cylinder set to supply gas fuel main engine / generator use, including a BOG control system and a tube bundle type high pressure gas cylinder set room 13 . The BOG control system includes a pressure gauge 4, an anti-vacuum pressure control valve 5, a thermometer 6, a flow meter 7, a filter 8, a gas compressor 9, a hydraulic remote control stop valve 10, a pendulum check valve 11, and a heat exchanger 12. , connected to the tube bundle type high pressure gas cylinder group chamber 13 in turn, and then through the pressure gauge 4, the hydraulic remote control cut-off valve 10, the pendulum check valve 11, the gas pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com