Rotary mechanical friction interface in-situ information acquisition device

A technology of mechanical friction and acquisition devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to detect, and achieve the effect of stable rotation speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

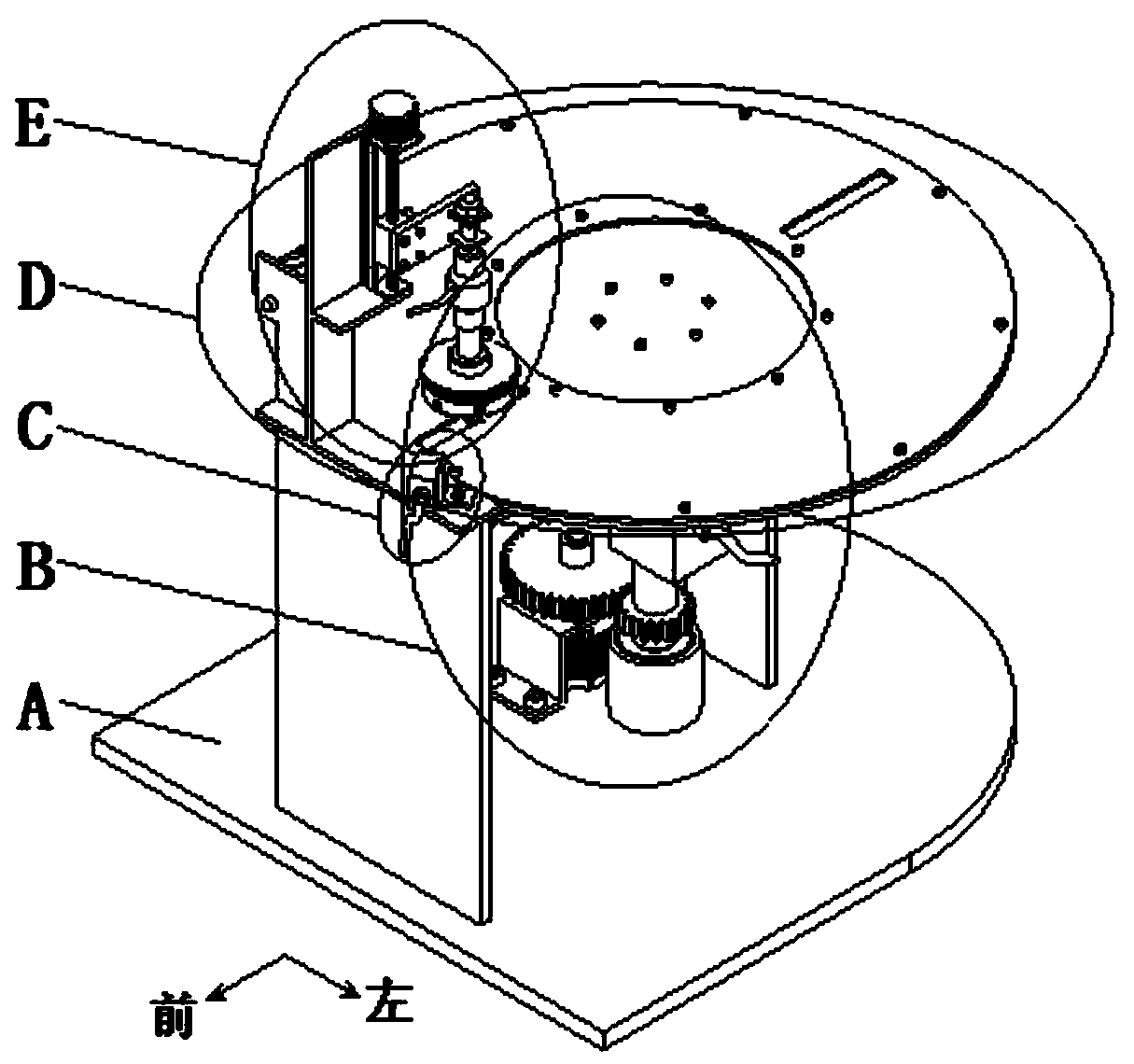

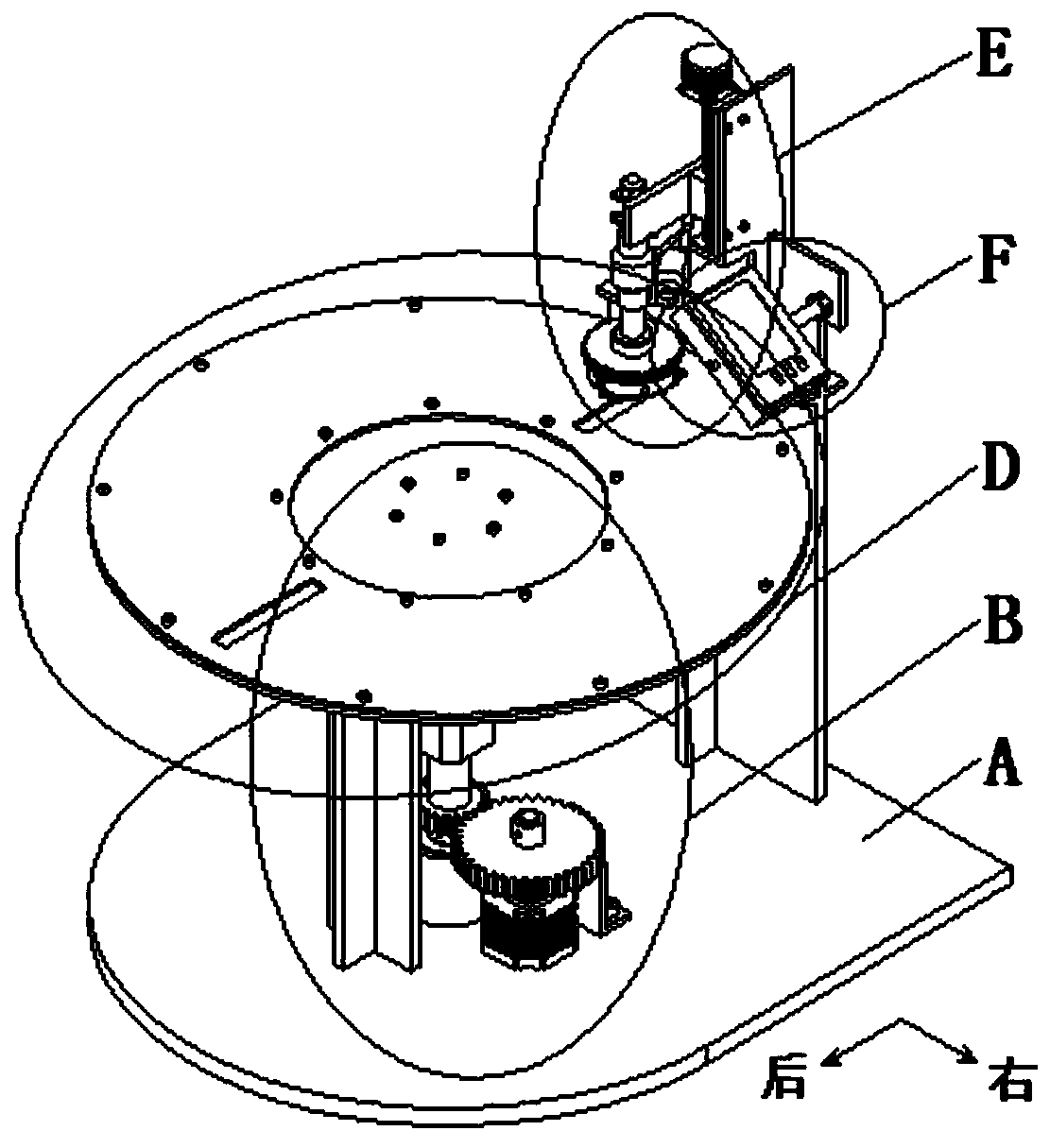

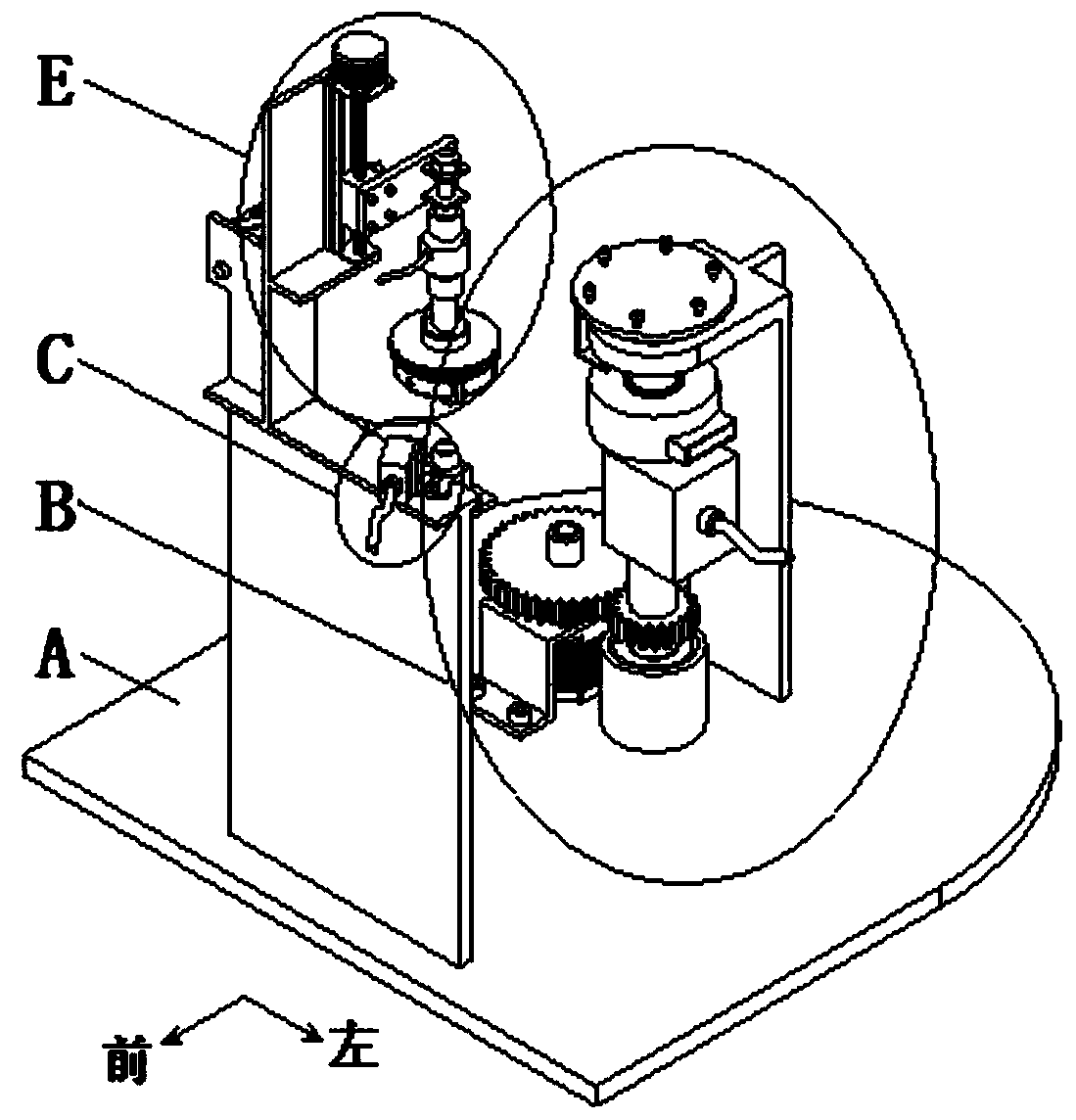

[0032] The present invention is described below in conjunction with accompanying drawing.

[0033] as attached Figure 1 to Figure 4 As shown, the present invention is composed of a test bench base A, a power mechanism B, a side monitoring mechanism C, a friction mechanism D, a loading mechanism E, an infrared monitoring mechanism F, and a bottom monitoring mechanism G. The outer ring of the bearing I19 in the power mechanism B is connected to the The inner ring of the hollow column 14 in the base A of the test bench is connected by interference; the outer ring of the upper part of the flange shaft 24 in the power mechanism B is movably connected with the hole 12 of the flat plate IV11 in the base A of the test bench; the motor mounting frame in the power mechanism B The lower horizontal plate of 15 is fixed to the middle part of the bottom plate 1 in the base A of the test bench, and is on the right side of the hollow column 14 in the base A of the test bench; the bracket I35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com