Micro-spacing display lamp panel avoiding light crosstalk interference and manufacturing method of micro-spacing display lamp panel

A micro-spacing and optical interference technology, applied in the direction of instruments, electrical components, electrical solid devices, etc., can solve problems such as difficult to achieve production inspection, inability to effectively improve mutual interference of light, inability to precisely control thickness and uniformity of light output effect, etc. Achieving good light-emitting effect, improving display effect and excellent light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

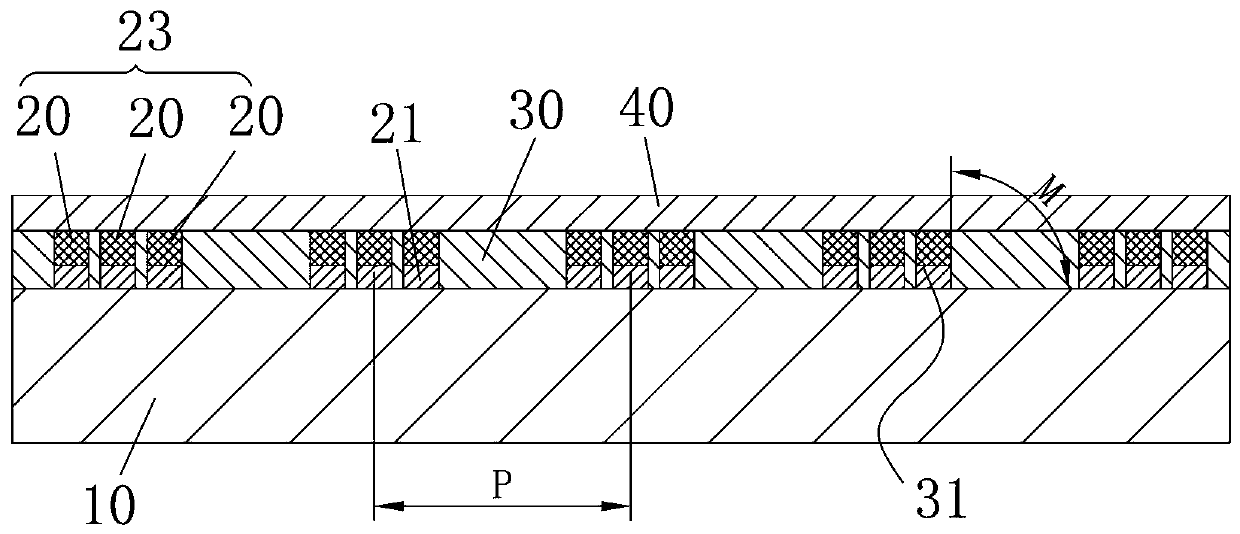

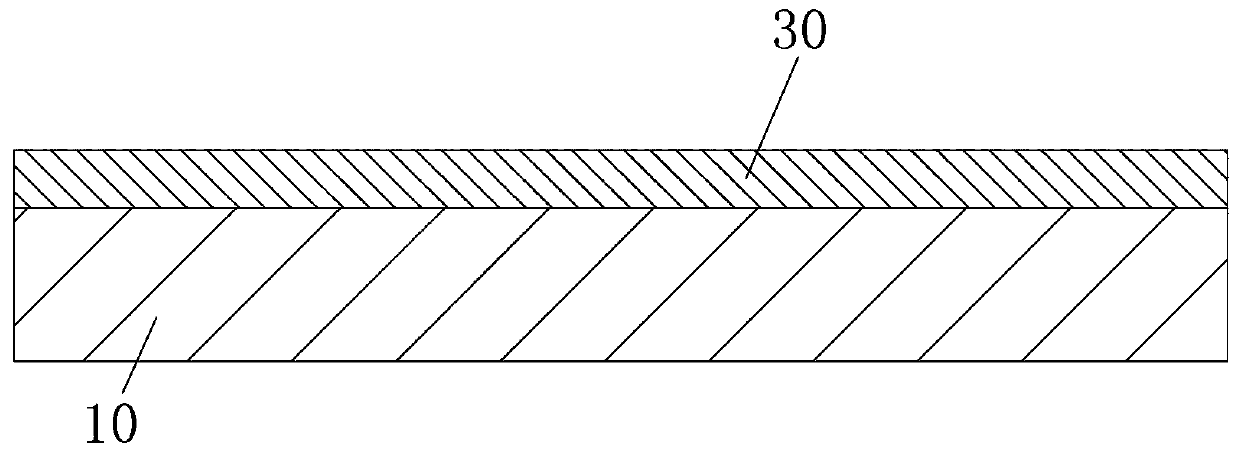

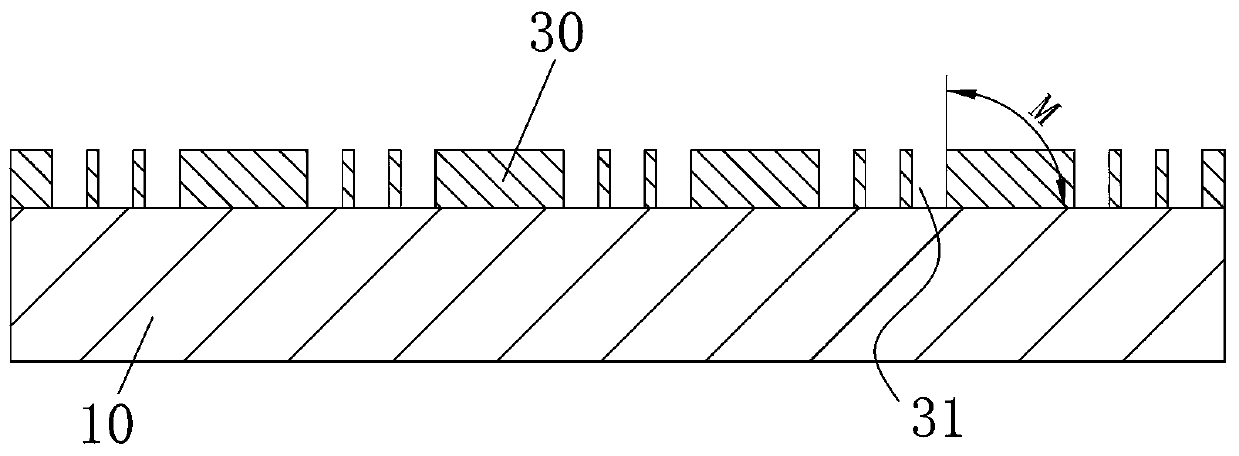

[0040] Such as figure 1 As shown, the first embodiment provided by the present invention, a fine-pitch display light board for avoiding cross-light interference, includes a circuit board 10 , LED chips 20 , a light-shielding layer 30 and a protective layer 40 . The light-shielding layer 30 is attached to the surface of the circuit board 10, and the light-shielding layer 30 is provided with a plurality of accommodation holes 31, and each LED chip 20 is arranged in one accommodation hole 31 and is conductively bonded to the circuit board 10 through the conductive bonding layer 21 to accommodate The inner wall of the hole 31 shields the light emitted from the side of the LED chip 20 ; the protective layer 40 is attached to the surface of the light shielding layer 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com