Battery charging feedback system and its control method, excavator

A feedback system and battery technology, which is applied in secondary battery charging/discharging, battery circuit devices, secondary battery testing, etc., can solve the problems of inability to feedback battery performance, inability to monitor the interaction of engine shutdown time, battery power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

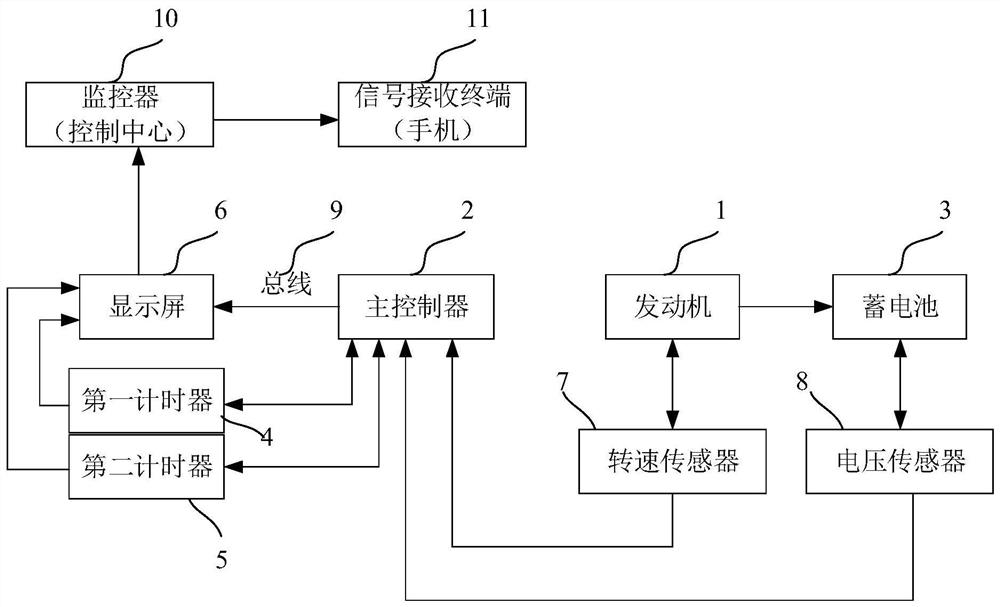

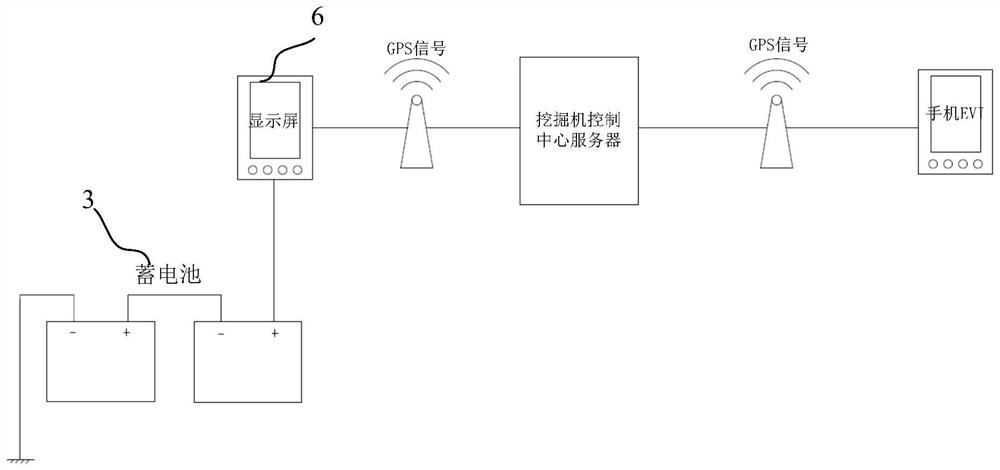

[0027] Please refer to figure 1 , the present embodiment provides a battery charging feedback system, which can be applied to equipment such as excavators. When these equipments are working, the engine 1 of the equipment has its own generator to automatically charge the battery 3, and the power stored in the battery 3 ensures that the equipment can start normally. But when equipment does not work for a long time, the electric quantity of accumulator 3 can be lost, and at this moment needs to start equipment to make engine 1 run and thus accumulator 3 is charged. This embodiment provides a battery charge feedback system, which can automatically monitor the power condition of the battery 3 and the operation of the engine 1. When the battery 3 is running out of power, it can automatically send a signal to remind the user to start the engine 1 to charge the battery 3. At the same time, it can also monitor and feed back the power usage time of the battery 3 to reflect the performan...

Embodiment 2

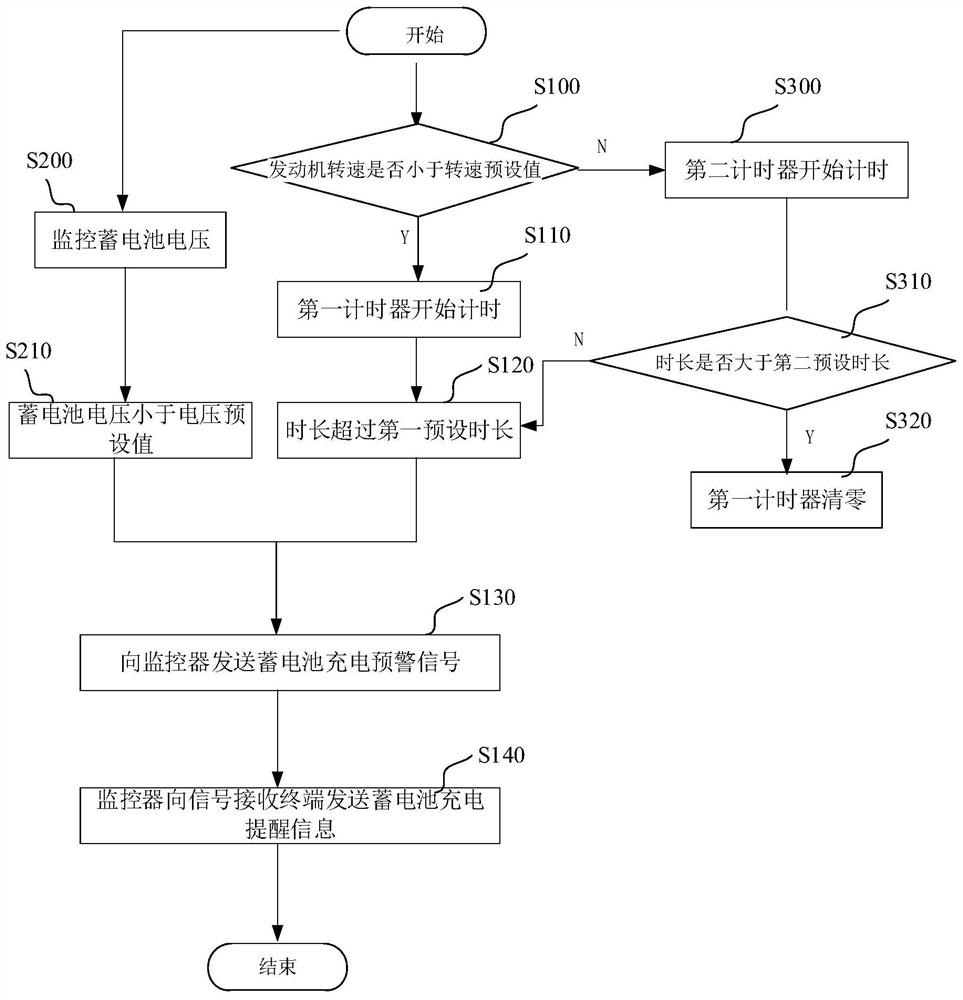

[0056] Such as image 3 As shown, this embodiment provides a control method for a battery charging feedback system, using the above-mentioned battery charging feedback system, the method includes:

[0057] S100: judging whether the engine 1 speed is lower than a preset value of the speed.

[0058] S110: when the rotation speed of the engine 1 is lower than the preset rotation speed value, the first timer 4 starts timing.

[0059] The rotational speed of the engine 1 is obtained according to the rotational speed signal of the rotational speed sensor 7 , and when the rotational speed is lower than a preset value of the rotational speed, the first timer 4 is started to count time.

[0060] S120: The duration exceeds a first preset duration.

[0061] When the rotation speed is lower than the preset value of the rotation speed, it is determined that the engine 1 is in a shutdown state, and the duration recorded by the first timer 4 is the shutdown duration of the engine 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com