Anti-blocking device of powder-liquid mixing pump

A powder-liquid mixing pump and anti-blocking technology, which is applied in the direction of mixers, fluid mixers, transportation and packaging, etc., can solve the problems of affecting production efficiency, prone to blockage of powder-liquid mixing equipment, and increasing labor costs, etc., to achieve The effect of simple structure, good adaptation to the working environment and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

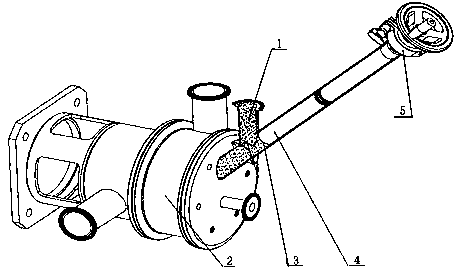

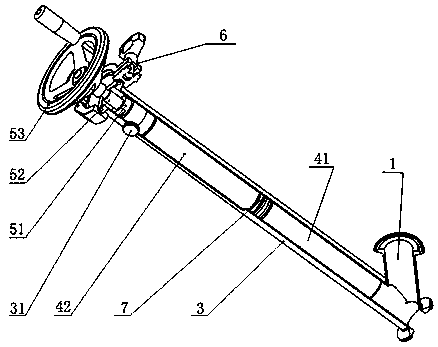

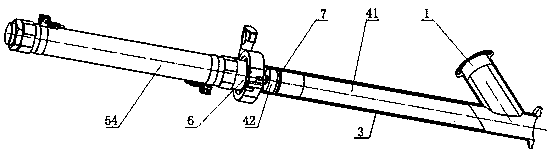

[0019] The following will combine Figure 1-4 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0020] Such as figure 1 The anti-blocking material device of the powder-liquid mixing pump includes a pipe fitting 3 that communicates with the powder inlet 1 and the pump chamber 2 of the powder-liquid mixing pump. The upper driving mechanism 5 drives the movement. When the powder-liquid mixing pump is started, the solvent and powder are sucked into the pump from the liquid inlet and powder inlet respectively, and the rotor in the pump rotates at high speed, so that the powder and liquid are fully mixed and dispersed in the pump chamber. After running for a period of time, as the concentration of the slurry increases, the viscosity increases, and the pipeline is prone to blockage. When a blockage occurs, the driving mechanism dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com