Method for machining speed ratio wheels

A processing method and speed ratio technology, which is applied in the processing field of speed ratio wheels, can solve the problems of high production cost, large process surplus, and medium blank weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

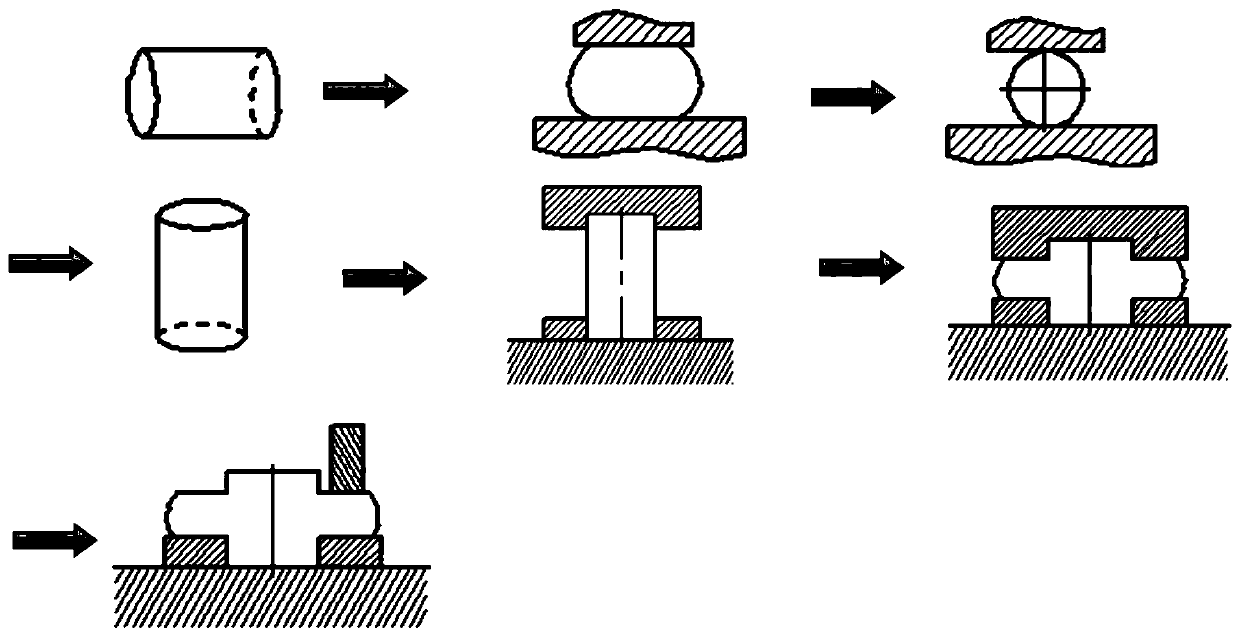

[0017] A kind of processing method of speed ratio wheel, see figure 1 : Loading and unloading from the raw material, then upsetting the obtained blank, and then elongating to obtain the corresponding blank, then placing the blank in the corresponding forging tooling for forging pre-forming, the formed blank has a double-boss structure, and then passed The tool trims and shapes the speed ratio wheel of the corresponding model.

[0018] When the tool is trimmed, the corresponding side of the single-side tooling is trimmed, and the double-boss structure is turned over after the one-side trimming, and the other side is trimmed through the single-side tooling to obtain the corresponding model of the speed ratio wheel after the double-sided trimming is completed;

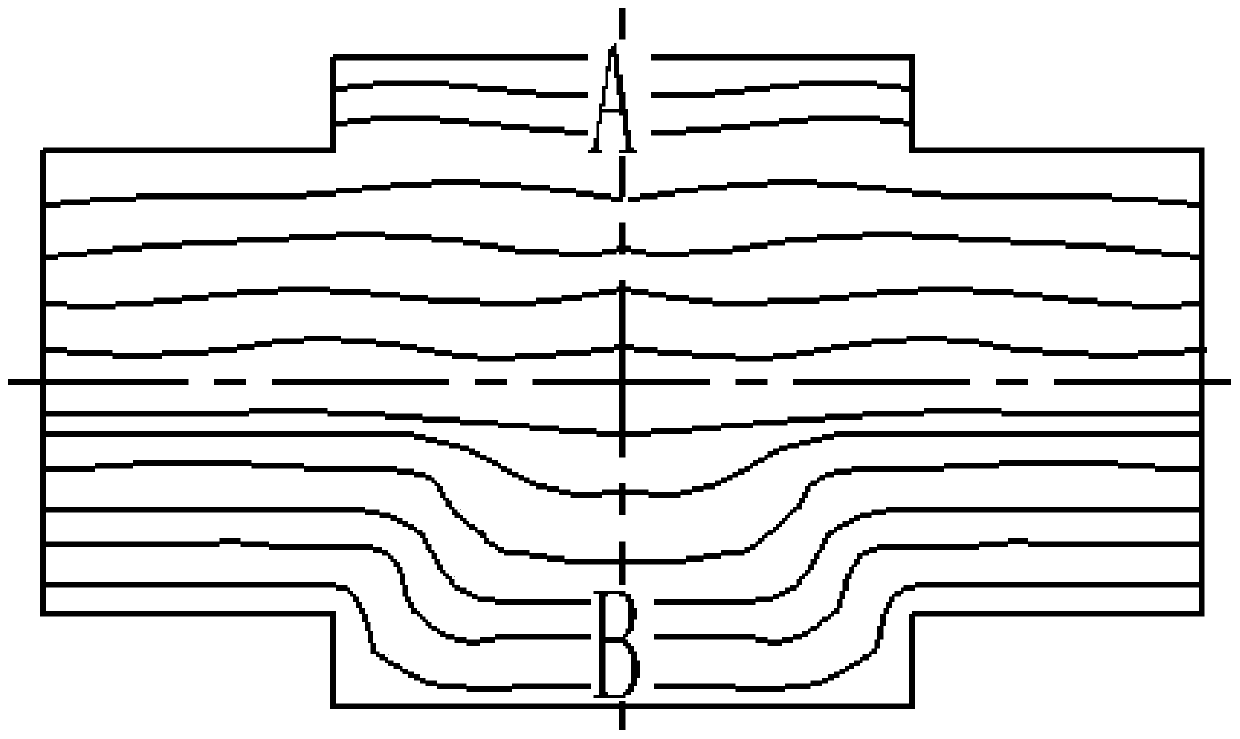

[0019] The size of the inner hole of the forging tool is equal to the size of the hub of the product, and the size of the blank can be put into the inner hole of the forging tool, and then the forging tool forges the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com