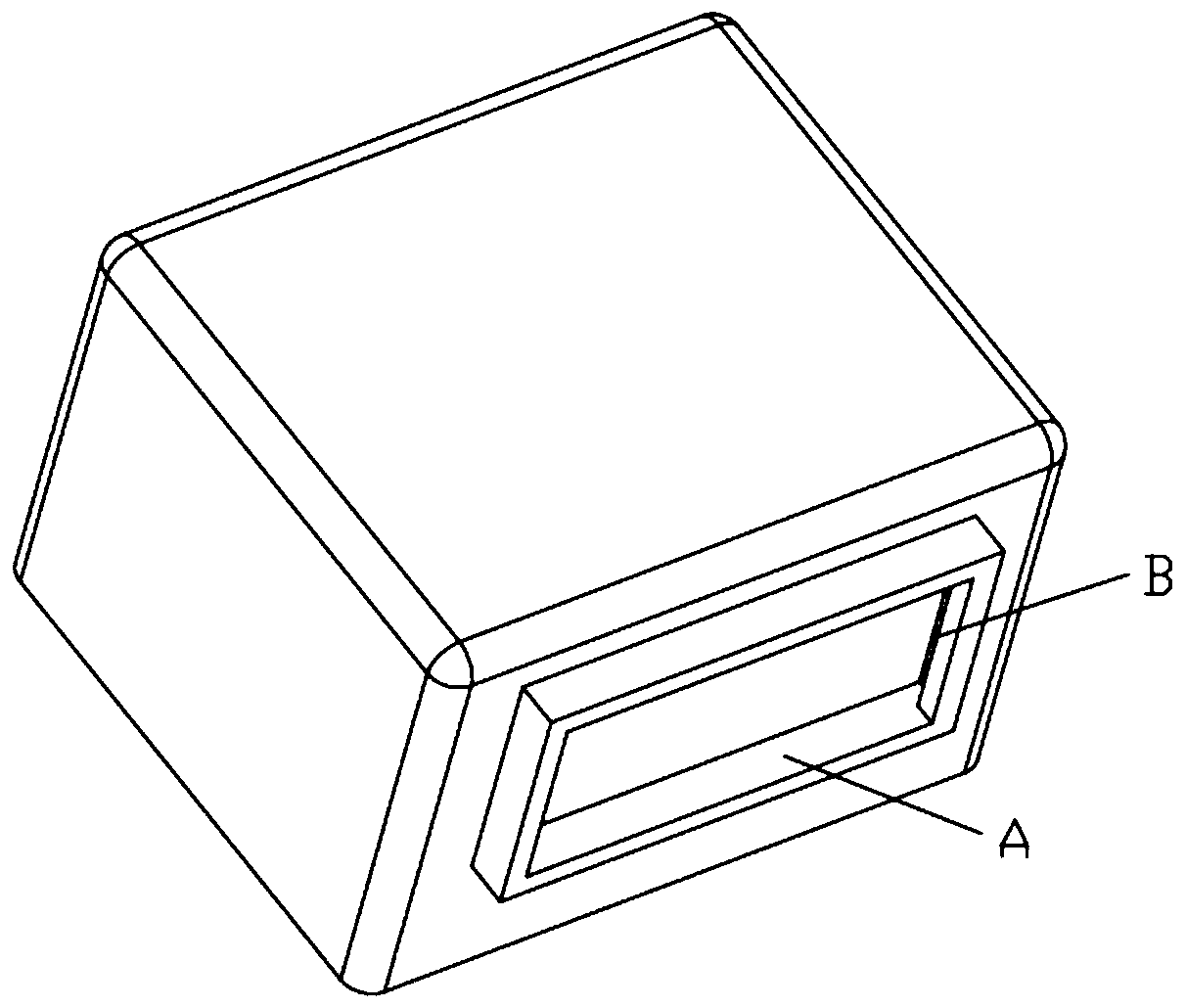

Bidirectional side core-pulling mechanism of mold

A side core-pulling and mold technology, which is applied in the field of molds, can solve the problems of easy interference and difficult core-pulling molding at the same time, and achieves the effects of simple structure, low manufacturing cost and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

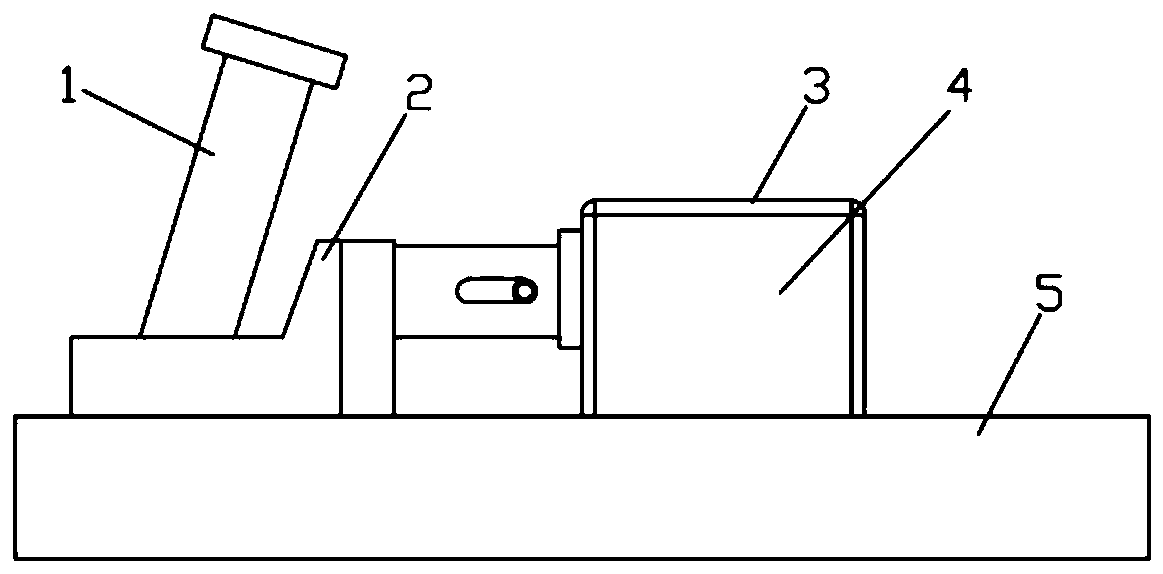

[0027] This embodiment provides a Figure 2-4 The two-way side core-pulling mechanism of the mold is shown.

[0028] The inclined guide post 1 is fixed on the fixed mold side of the mould.

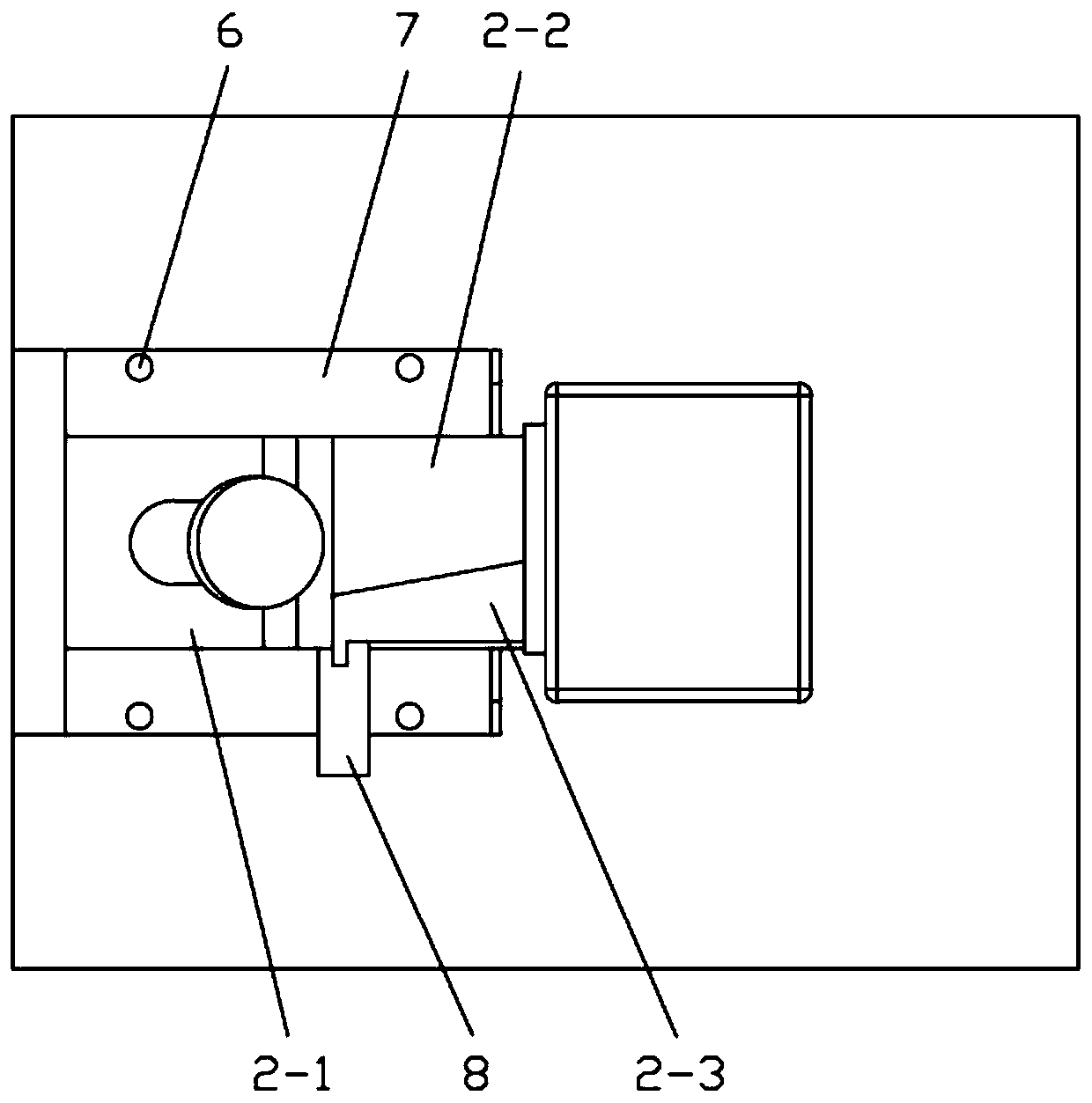

[0029] The movable template part includes a side drawing slider assembly 2 , a core 4 , a movable template 5 , a pressing plate 7 , and a guide limiting plate 8 . The core 4 is fixed on the movable template 5 . Two pressure plates 7 are fixed on the movable template 5 by bolts 6 to form a T-shaped groove matching the T-shaped structure at the bottom of the slider 2-1. Guide limit plate 8 (as Figure 8-9 shown) is also fixed on the corresponding position of the movable template 5 by bolts.

[0030] Side drawing slide block assembly 2 comprises slide block 2-1 (as Figure 5 shown), the fixed side core 2-2 (such as Figure 6 Shown), active side core 2-3 (such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com